Side channel blowers play a critical role in pneumatic conveying systems, offering efficient material handling solutions across industries. Here’s an in-depth analysis of their application and benefits:

1. Mechanism and Functionality

Side channel blowers generate vacuum or pressure to transport materials through pipelines. They use a rotating impeller to transfer kinetic energy to the gas (air), which is then converted into pressure. This process enables the movement of dry, powdered, or granular materials in both dilute-phase and dense-phase conveying systems.

Single-stage vs. two-stage: Single-stage blowers discharge material after one rotation, while two-stage models compress gas further for higher differential pressures, suitable for longer-distance conveying.

Oil-free operation: Their contact-free design ensures no lubrication is needed, making them ideal for food, pharmaceuticals, and other contamination-sensitive industries.

2. Applications in Material Handling

Dilute-phase conveying: Utilizes high airflow at low pressure (below 1 bar) for lightweight or non-abrasive materials like grains, plastics, or flour. Side channel blowers (e.g., ring blowers) serve as prime movers here, offering high throughput and cost-effectiveness.

Dense-phase conveying: For fragile or abrasive materials (e.g., chemicals, minerals), higher pressure (above 1 bar) is required. Two-stage blowers provide the necessary force with minimal material degradation.

Industry-specific uses:

Food and pharmaceuticals: Ensures sanitary, dust-free transport of ingredients.

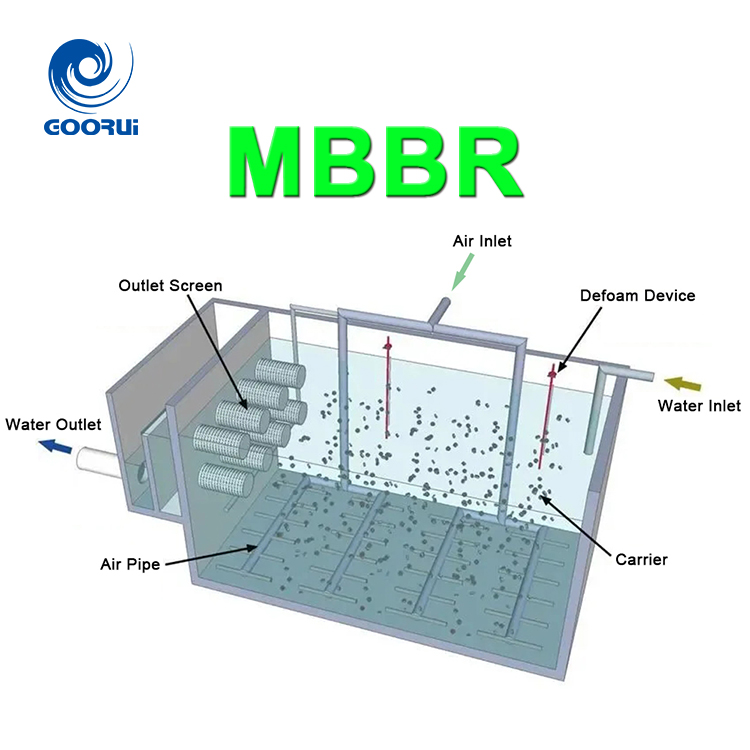

Wastewater treatment: Aeration and sludge handling.

Packaging and textiles: Moves fibers, powders, or finished products efficiently.

3. Key Advantages

Energy efficiency: Modern designs, such as maglev turbo blowers, reduce energy consumption by 30–40% compared to traditional Roots blowers.

Low maintenance: Open impeller design prevents dust buildup, reducing vibration and wear.

Versatility: Handles diverse materials, including free-flowing, non-free-flowing, and fragile products.

Noise reduction: Operates below 80 dB, suitable for indoor environments.

4. Technical Specifications

Flow rates: Ranges from 40 m³/h to 2,200 m³/h, accommodating small-scale and industrial needs .

Pressure capabilities: Up to 10,000 Pa (1 bar) for standard models.

Material construction: Aluminum or cast-iron housing ensures durability, while stainless steel variants meet hygiene standards.

Conclusion

Side channel blowers are integral to modern pneumatic conveying solutions, offering flexibility, efficiency, and reliability. Their ability to handle diverse materials and operational demands makes them a cornerstone in industries ranging from food processing to wastewater management. For tailored solutions, consulting with manufacturers like Pneucon or Busch ensures optimal system design.