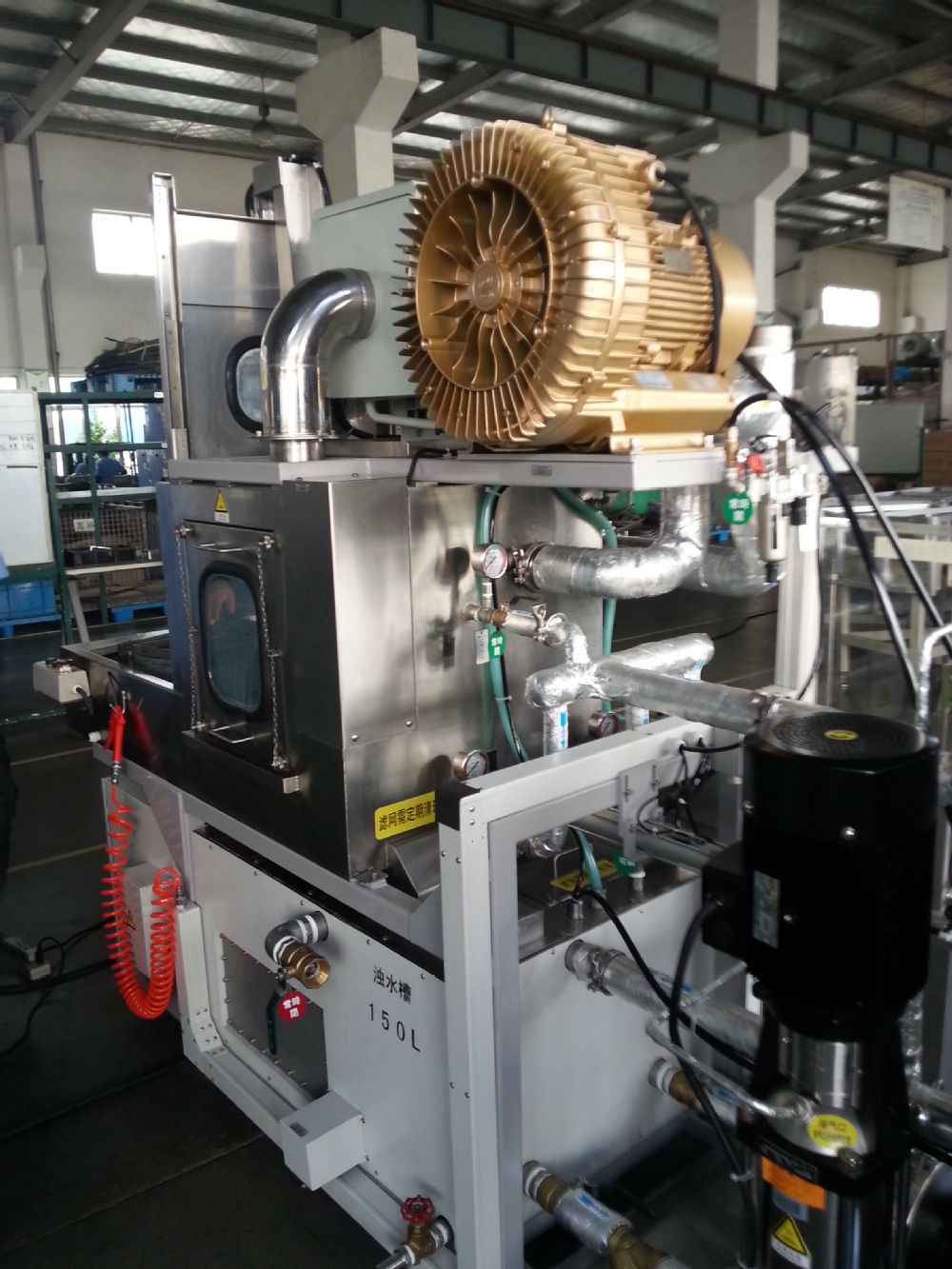

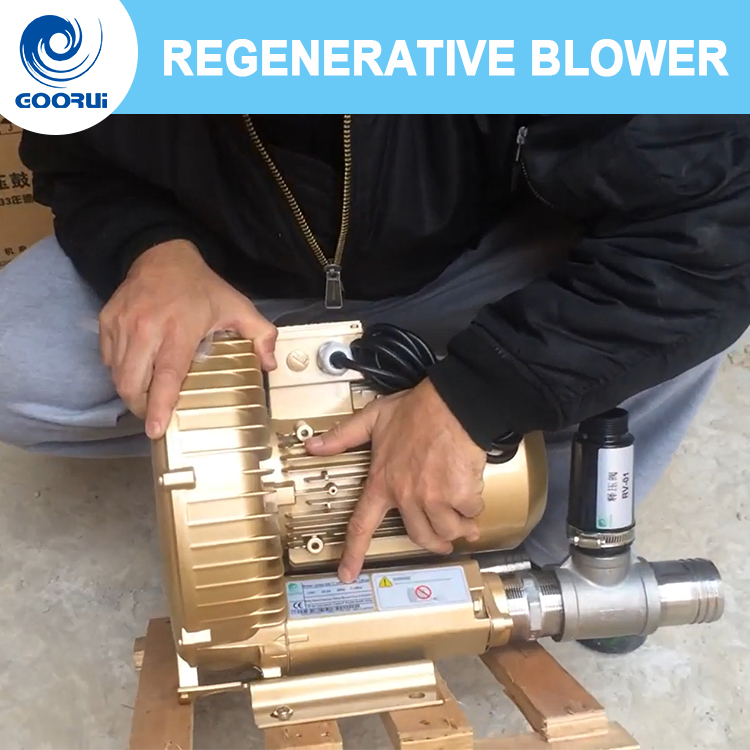

GOORUI blowers have been replaced compressed air and other high-pressure air-moving devices in thousands of metal-finishing lines and furnishclean, oil-free, stable air for reliable energy-efficient air agitation of tanks. Eachinstallation of a regenerative blower has decreased a plant’s operating expensesand improved plating quality.

The use of low-pressure air to agitate metal finishing plating, anodizing, rinse-and-wash tank solutions represents a milestone in the advancement of electro-plating technique. While decreasing your operating costs, you can expect low-pressure air agitation to:

(1) Enhance plating quality,

(2) Increase production,

(3) Permit a more continuous plating process.

Enhances Plating Quality.

Low-pressure air from GOORUI regenerative blower provides efficient removal of cathode films with higher speed plating,thus decreasing polarization. Polarization is the increase in resistance of the elec-trodes that results from the chemical reactions of metal finishing, and causes adrastic slowdown of the electrolytic reaction needed to produce the process.

Increases Production.

Low-pressure air helps dislodge dirt particles,flushes away dissolved grease, and ensures contact with the plating solution. Theair also increases rinsing efficiency, which reduces the amount of rinse waterrequired, thus minimizing demands on a plant’s waste treatment system.

Permits Continuous Plating Process.

Air agitation also preventsexcess collection concentration, thus lowering drag out. Concentration circula-tion will keep the solution fresh and minimize the required solution change. Inaddition, agitation will maintain an even solution concentration and prevent stratification in the separation and division of chemicals in solution.