On the following article, we will provide you with more detailed information on mobile wastewater containers and how they operate.

Most wastewater container treatment containerized systems, incorporate different treatment processing stages. Their main function is to discharge liquid waste and other agents. This can be accomplished by mechanically pretreating the raw wastewater through the employment of screw screens worked by the side channel blower.

Usually installed on the containerized wastewater treatment plant, these screens are designed to eliminate large inorganic particles and other coarse aggregates such as sand and grease.

All of these processed inorganic wastes are ultimately further treated and disposed of. Depending on the plant size, waste disposal can be outsourced or collected into tanks along with other wastes to be later eliminated.

Occasionally following the mechanical screening by the side channel blower, wastewater may be needed to be buffered. Wastewater buffering is a process aimed to further purify the water by making it flow through the buffer tanks. Here we have listed the different types of waste watering buffering:

- Aerated buffering: intended for carbon-based compounds breakdown.

- Anoxic buffering: designed for pre-denitrification. (removal of nitrogen or its compounds)

- Unventilated buffering: thought to manage hydraulic peak flows.

Fully automated mobile wastewater treatment units

Fully automatic mobile wastewater treatment units differ from its counterparts as they are completely automated. Integrated with energy-saving modes they can better manage the wastewater volume. In addition, fully automatic systems are highly reliable and require minimal working personnel management and maintenance.

Wastewater treatment is required in urban drainage system and industrial processes (such as food, beverage, pulp and paper making). In many countries, the demand for wastewater treatment plants is growing rapidly to treat more and more wastewater while avoiding pollution.

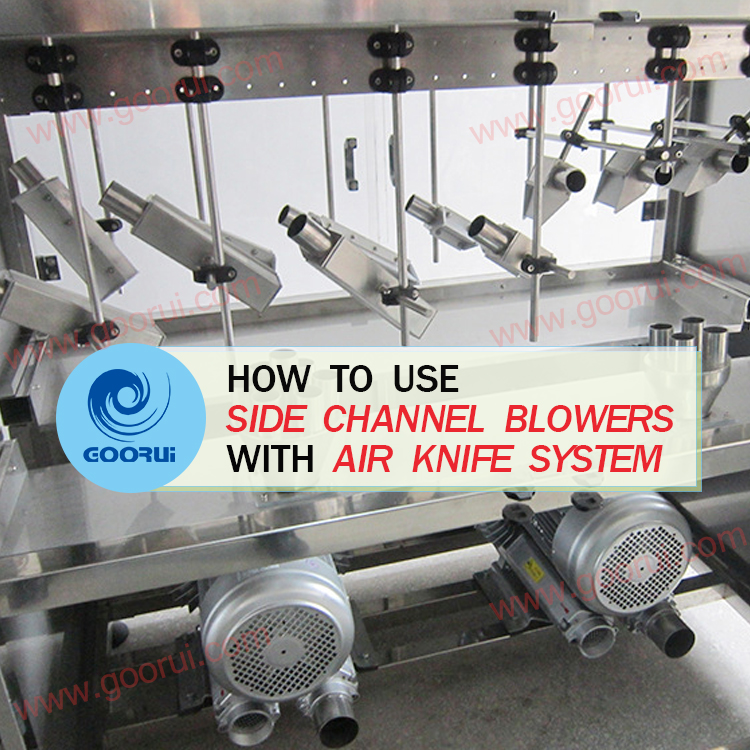

According to the specific needs of the wastewater treatment plant, GOORUI developed the side channel blower technology, which provides a reliable air source for the aeration in the wastewater treatment process. If you have any requirements for regenerative blowers, please feel free to contact GOORUI. We will provide you with the most effective solution for wastewater containers.