As an essential tool of industrial production, the side channel blower, also known as the regenerative blower, has been widely used in our daily life. However, it is a machine that is often neglected by us, let alone its working principles.

Keep reading, and this article will walk you through how does a side channel blower works and where you can find it.

Working principle of side channel blowers (regenerative blowers)

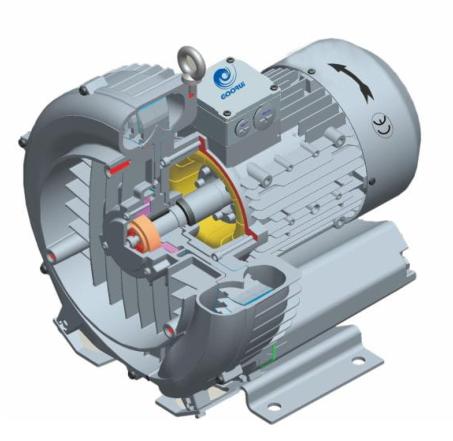

The blower is a kind of machine that uses the air pressure difference to draw in, compress, and finally spit out the air. The structure of a blower is usually composed of an impeller, an inlet door, a frame, a transmission housing, a coupling or pulley (triangle belt), and a motor.

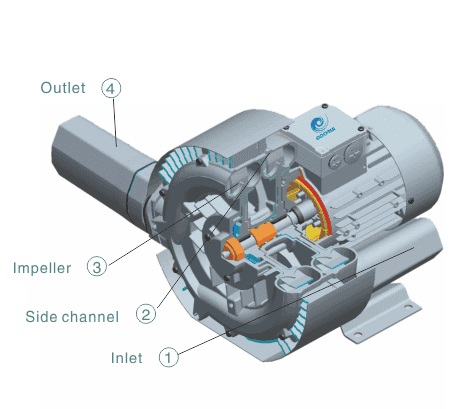

When the power is on, the air enters the machine through the channel on the left side of the blower (Figure 1). When the air enters the side channel (Figure 2), it will be compressed due to the rotation of the impeller. Rotating impeller (Figure 3) gives the gas speed in the direction of rotation. At the same time, the centrifugal force on the blade accelerates the gas outward and increases the pressure.

After numerous times of rotary and compression, the air between the blades of the impeller rotates spirally, and the kinetic energy of the gas increases, driving the gas pressure along the side channel to further increase until the air can be discharged out of the blower through the air outlet (Figure 4).

The impeller is directly installed on the motor rotor, which achieves an entirely non-contact compression. When the impeller starts to rotate, there will be pressure in the machine body, and the unique design in the blower will not make the air backflow.

This means that regenerative blowers can be used to blow air or draw in the air with positive, and can also be used to inhale positive or negative pressure (vacuum) air.

Application of side channel blowers (regenerative blowers)

As we don’t know about the blower, we have no ideas even though there is a blower working nearby. Since the blower can blow or inhale air and widely applied in industrial production, we can find it everywhere:

- Pond aeration equipment

- CNC machines

- Engraving equipment

- Industrial vacuum systems

- Packaging

- Printing presses

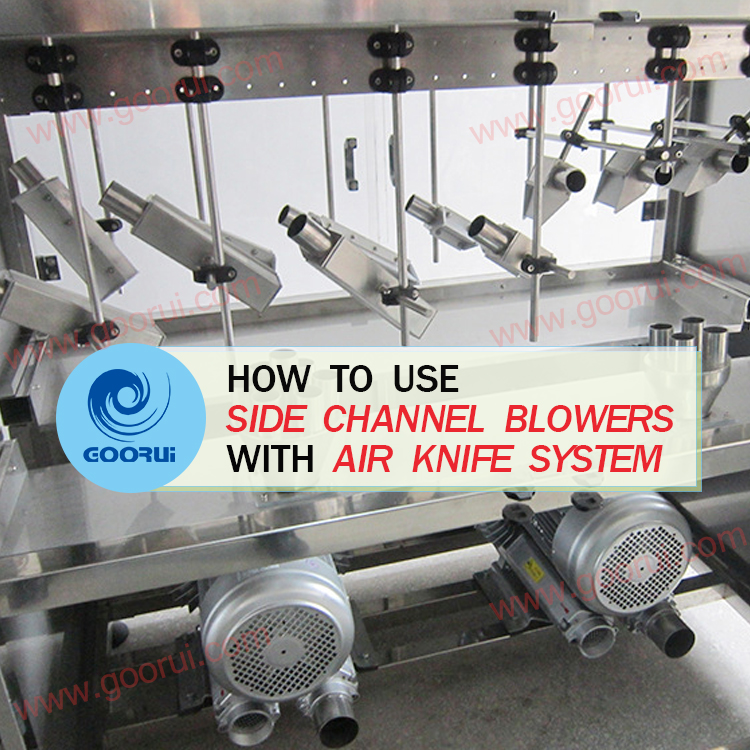

- Air knife system

- WWPT/SEP wastewater treatment plant

One of the reasons why regenerative blowers are applied so frequently is that they are virtually maintenance-free. They can be operated up to 30,000 hours without maintenance. Besides, a regenerative blower is considered as a contact-free machine, which ultimately ensures the personal safety of the operator.

Regenerative blowers are an essential component to many types of machines and in a wide variety of industries; thus, understanding their functions and applications is incredibly helpful. If you have any questions about blowers, you are welcome to consult GOORUI. GOORUI, a company with 10 years of experience specializing in the production of blowers, can provide you with not only professional services but also high-quality blowers.

Looking for regenerative blower manufacturers to supply this essential machine for your company?

Contact GOORUI team for more information on regenerative blowers.