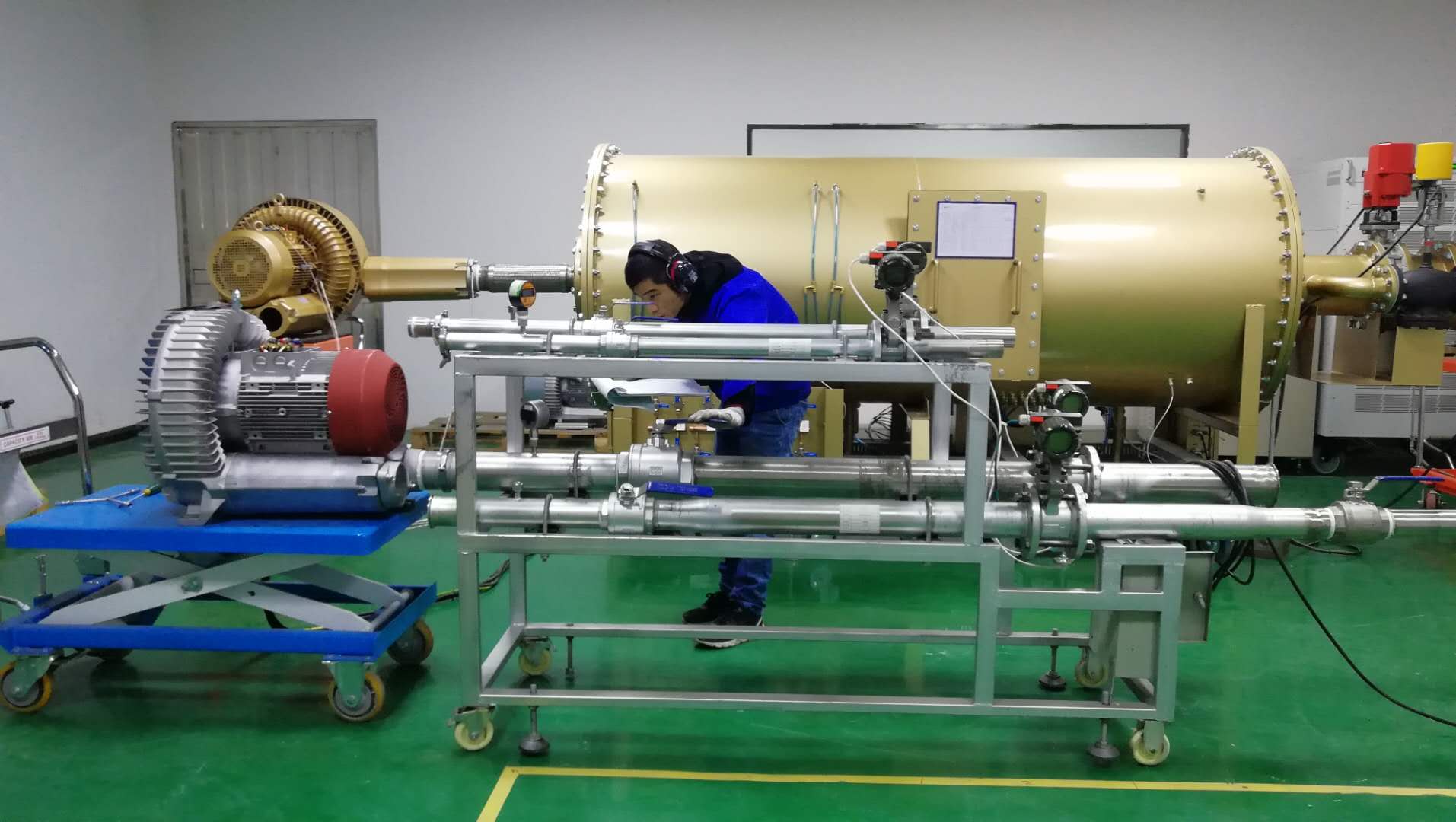

The application of blowers is now more and more extensive, and it can be seen almost everywhere in our daily life, such as aquaculture, hot spring pools, textile equipment, and even in blowing systems. So, when we operate the GOORUI blower, what should we pay attention to ensure the smooth operation of the system?

Before starting operating the regenerative blower, it would be best if you check to make sure all the parts of the blower are normal. The aspects you need to make sure are as follows:

- Make sure that you had read through the operating manual and figure out the contents very well.

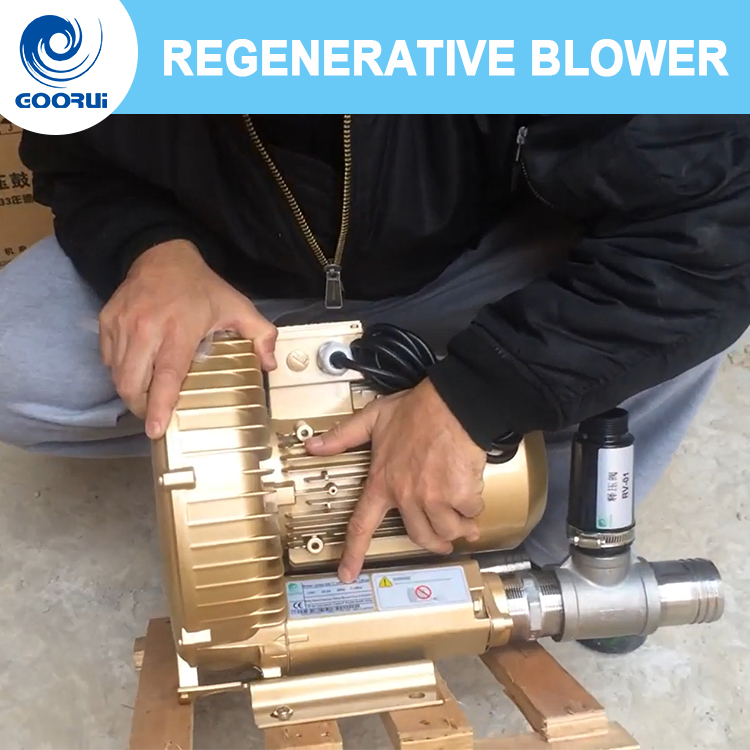

- Make sure the specification of the blower meets the design requirements.

- Make sure the appearance of the blower is intact.

- Ensure that the voltage of the blower is stable; if not, a voltage regulator needs to install.

- Ensure the inlet of blowers without any impurities.

Next, you may want to know the cautions of the installation of the blower, which you can look up in the installation manual of a regenerative blower.

- When installing, it needs to confirm double that the applied voltage of the blower is the same as that of the power supply. In the case of the same voltage, the connection of the terminal of the blower shall also be correct. The connection method can refer to the instructions on the nameplate of the blower. When each wire is locked, and there is no break, you can install the ground wire.

- The blower shall be installed in the room with a temperature below 40 ℃ and relative humidity below 80%. If it has to be installed outdoors, it needs to be covered and protected from wind and rain for that the parts may be damaged by rain, causing the machine not to work usually.

- Because the blower is made of ADC 12 (Aluminum – Alloy Die Castings), corrosive gas can not be inhaled and transmitted by blowers; otherwise explosion will occur. If you need the explosion-proof function, you can contact GOORUI to design a unique explosion-proof blower.

- The blower is not allowed to be installed in the dusty environment. If it has to be installed, the air filter and air filter barrel need to be added. Meanwhile, it is necessary to ensure that no dust falls into the cooling fan of the blower.

- When using the blower, it is necessary to go to a well-ventilated place, and it cannot be used in a closed room or a sealed box.

- The blower should be installed in a spacious place for the convenience of maintenance.

- The blower shall be installed in a place without vibration. If necessary, a shockproof gasket shall be added around the blower, and the hose shall be used to connect the blower.

- When selecting the connecting pipe, the one with thermal stability is recommended, and you have to ensure that the pipe will not leak when working.

- When testing the side channel blower, you also need to check out that if there is debris trapped in the air outlet of the blower.

- Refer to the arrow on the inlet and outlet of blower, make sure the blower will not run reversal. Otherwise, it will run with low efficiency and may cause serious problems.

Improper operation of the blower can easily lead to safety accidents. Therefore, when the previous inspection work is done, we cannot operate the blower lightly. There are also some points we need to pay attention to during operation.

- Please do not touch the blower by hand when the blower is running as it may produce high temperatures.

- A suitable overload switch needs to install to prevent the blower from burning out as the current of the blower may change while running.

- It is better to install a vacuum or pressure relief valve to protect the blower from burning out since the blower should work within the pressure it can bear.

- Filter bags are needed if the water, dust, hard material, powder need to be filtered before using the blower.

- If an air filter needs to be installed in the connecting pipe, it should be installed in a large area to prevent excessive pressure loss of the blower.

- The air filter, filter bag, and interior of the blower need to be cleaned regularly.

- The bearing, oil-seal, silencer need to replaced regularly, and the impeller, cover, metal mesh also need to be replaced periodically according to the service condition.

- Turn off the power and check the blower in time if the blower runs unsteadily or with big and un-normal noise.

If you need more information about the GOORUI blower, call us or email us;we GOORUI team will be happy to help you!