The air is diffused into thousands of tiny bubbles. As these bubbles move through the wastewater, oxygen is captured and the purification process takes place just like the stream. The air compressor is located outside the treatment system for ease of service. This keeps the compressor away from the corrosive environment and the potential problem of flooding.

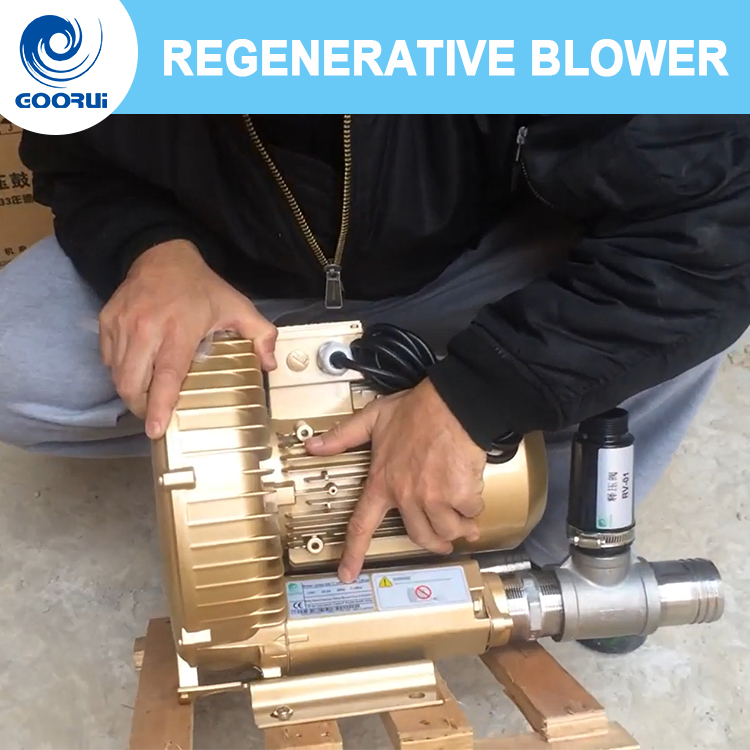

Microorganisms in an aquatic system require oxygen to breakdown waste material. This process is just one step in waste water treatment that ultimately results in a clean water source. When using our regenerative blowers and diffusers for aeration, we can assure maximum oxygen transfer efficiency in any waste water system.

To accomplish this aeration and purification, most systems use two separate compartments within a single treatment tank. Effluent from the home will enter the aeration compartment of the system. In this area, thousands of tiny air bubbles provide oxygen for the aerobic digestion process and mixes the compartment’s entire contents. These tiny bubbles quicken the aerobic digestion process. Aerobic bacteria then use the oxygen in the solution to break down the wastewater, converting it to an odorless liquid.

Flow Volume – is the hydraulic load or flow which is referenced as GPD or Gallons per Day. A typical three bedroom home with four people will have an approximate system flow volume of 360 GPD. Many factors contribute to flow volume such as flush toilets, sinks, showers, dishwashers and floor drains. Also to consider is the condition of these areas. Do the faucets leak? Do the toilets run? Is the homeowner conscious of water usage? There are systems available from several manufacturers as high as 1000 GPD and even 1500 GPD.

Waste Strength – The waste strength is referred to as the biological load on the system. The primary parameters used to measure the waste strength are: Biochemical Oxygen Demand or BOD, Total Suspended Solids or TSS and Fats, Oils, and Greases or FOG’s.