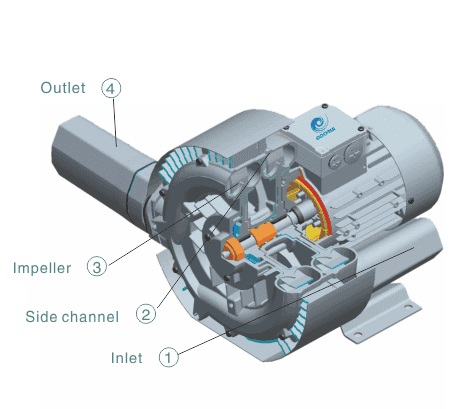

Sometimes users don’t pay much attention to some minor problems on side channel blowers, because they know that these will not pose a threat to the overall operation state of the equipment. As everyone knows, these small faults can very well become the source of major problems in the later period. This is also true for important equipment such as side channel blower, so any minor anomalies cannot be taken lightly, and the problem will become more and more serious if not resolved in time.

If observed carefully, you can find that there are still many abnormal performances that often occur on side channel blower, such as the following two situations:

1. Undesirable phenomena on side channel blowers’ bearings, including high temperature, turn cover, twist, angle error, etc., may cause abnormal bearings. Therefore, once a similar situation is found, the best way to deal with it is to use spherical roller bearings that can be automatically adjusted to the centre to avoid problems.

2. In addition to the above-mentioned phenomena, there is another phenomenon that is not easy to find, that is, the clearance of the bearing does not meet the requirements. Since the clearance inside the bearing is extremely important to the tightness of the bearing, when most of the bearing clearance gradually decreases with increasing temperature, the heat generated by the bearing will be greater than the heat dissipated, resulting in a The serious consequences of the series.

The two cases mentioned above must be given more attention. The failure rate of the side channel blowers depends on the importance of these cases.