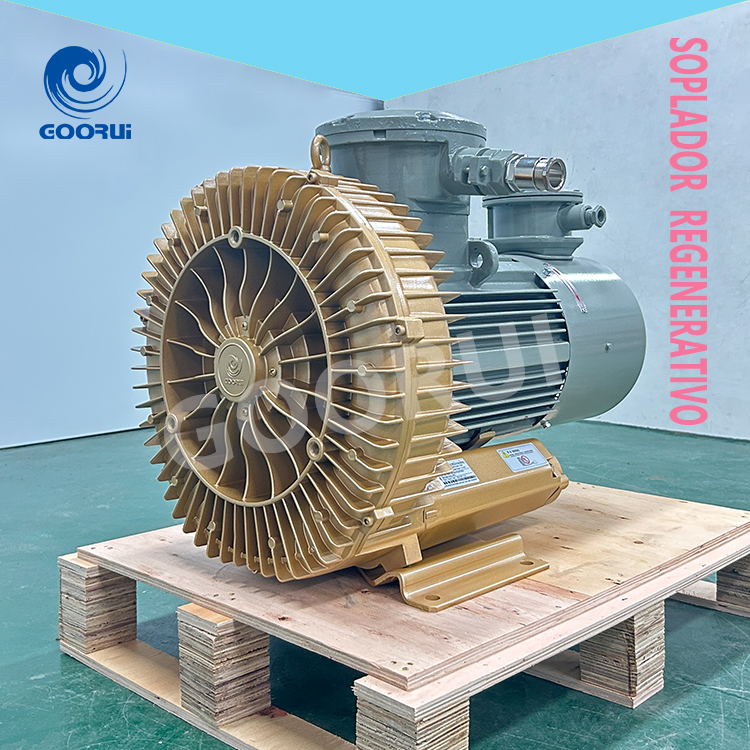

Regenerative blower ( also named side channel blower ,ring blower , vortex blower ) are one of the most versatile industrial blower types within the packaging industry. They provide high pressure or vacuum utilizing non-positive displacement flow, meaning air passes from one impeller blade to the other. Their design is contact free which causes no wear and makes them virtually maintenance free. They are oil-free and have a small footprint. They provide pulsation-free flow for a low vibration level and noise level. Their high-efficiency motors make their operational cost very low. Such features can be utilized by the packaging industry in many ways.

Processing:

- Bag & Packaging Filling– Open the bag/packaging and then place the product inside the bag/packaging; e.g. cereal, cookies, cinnamon buns.

- Cap Bottles – Position cap on bottles as they move along the product line; e.g. beverages, supplements, pharmaceuticals.

- Fill Bottles – Place product inside bottles as they move along the conveying line; e.g. beverages, supplements, pharmaceuticals.

Removal:

- Bottle Evacuation – Remove oxygen and contaminants from bottles prior to filling to provide hygienic conditions; e.g. beverages, cosmetics, pharmaceuticals.

- Drying – Often combined with air knife systems to remove moisture and debris prior to packaging; e.g. beverages, food cans, pharmaceutical bottles.

- Dust & Debris Collection – Remove and collect dust and debris from the area surrounding packaging machines.

- Excess Product Removal – Remove and collect packaging scraps, and remove imperfect packaging prior to filling; e.g. trim from plastic wrapped products, cardboard boxes not suitable for filling.

- Gas Removal – Evacuate air and other gases from packaging prior to filling to provide hygienic conditions; e.g. cereal, baked goods.