What is Pneumatic Conveying?

Pneumatic conveying uses compressed air, or gas, to transfer bulk materials, like powders and granules, from one processing center to another. Material is moved through an enclosed conveying line or tube using a combination of pressure differential and airflow from a blower or fan. The positive or negative pressure, inside the conveying line, moves materials safely with little damage or loss.

Vacuum Pneumatic Conveying System with a Container System

The process of pneumatic conveying can be seen in the image below, where plastic flakes are being conveyed in a dilute phase pneumatic system using an eductor valve.

The process of pneumatic conveying is a combination of well-engineered components that work together to move substances and materials safely, efficiently, and economically.

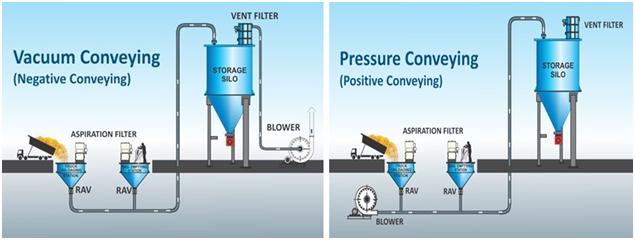

Vacuum vs Pressure

A vacuum system sucks materials through the pipeline and is ideal for pressure sensitive non- abrasive materials. A pressure system pushes material through the pipeline and can move abrasive materials. Quartz and copper sulfate are the types of abrasive materials that a pressure system will move.

Vacuum Conveying vs. Pressure Conveying

High Pressure blower

High Pressure blower is one of the two methods for moving material using a pneumatic conveying system. When designing a system, a major factor is the amount of pressure drop throughout the system, which is the most extensive at the end of the system. The force of the blower determines the flow rate at cubic feet per minute (CFM), velocity in meters or feet per second, and the pressure. It pushes the material down the pipeline.

Vacuum pump

Vacuum pump is another method of moving material. Vacuum systems are often used as part of a dilute phase system but can also be applied to dense phase systems. An electric driven vacuum pump is the most efficient and recommended method for producing the vacuum. As can be seen in the diagram, the vacuum conveyor is located to the right at the end of the pneumatic pipeline and pulls the material through.

Conclusion

- Pneumatic conveying systems use compressed air, or gas, to transfer bulk materials, like powders and granules, from one processing center to another.

- The positive or negative pressure in a pneumatic conveying line moves materials safely with little damage or loss.

- Pneumatic conveying systems use pipes or ducts to transport materials on a stream of air.

- Materials transported by pneumatic conveying systems include cement, fly ash, starch, sugar, salt, sand, plastic pellets, oats, polymers, lime, soda ash, plastic resin, plastic powder, dry milk, and feeds.

- Pneumatic conveying systems are widely used because of their efficiency, cost effectiveness, and flexibility.