It is often misunderstood how a blower works when connected to other components of a blower system, which can lead to the wrong tool selection for a procedure. In this article, we intend to clarify the issue in simple language by explaining the blowing system and the effect of a high-pressure blower in this system, so stay tuned for the rest of this article.

What is blowing system?

Many industries use the blowing system in different parts. The primary purpose of using this system is to remove scrap as well as drying and cooling. The function of this system is to use a blower such as a high-pressure blower to direct the flow of air or gas from one point to another. Any industry may require conveying, ventilating, cooling, aspirating, exhausting or other means of flow. In this case, this system is the most useful tool to blow them off quickly without stopping the line, which an industrial blower can do well.

How high-pressure blower is applied in the blowing system

Blowing system utilizes a mix of pressure and air to move materials through a line or pipe, from one area to another. The whole framework regularly includes a source of the high-pressure blower, a tube to transport the materials, and a collection vessel. Where the high-pressure blower is situated in the framework decides if it pushes the material by blowing it ahead, or making a vacuum that sucks it through the pipeline.

When situated at the framework’s beginning, the air mover pushes air through the system, and the system operates under pressure by blowing it forward. When located at the system’s end, the industrial blower pulls air through the system, and the system runs under vacuum, drawing the materials in reverse. By controlling the blowing pressure or vacuum and inside the lines, the course successfully and efficiently transfers materials.

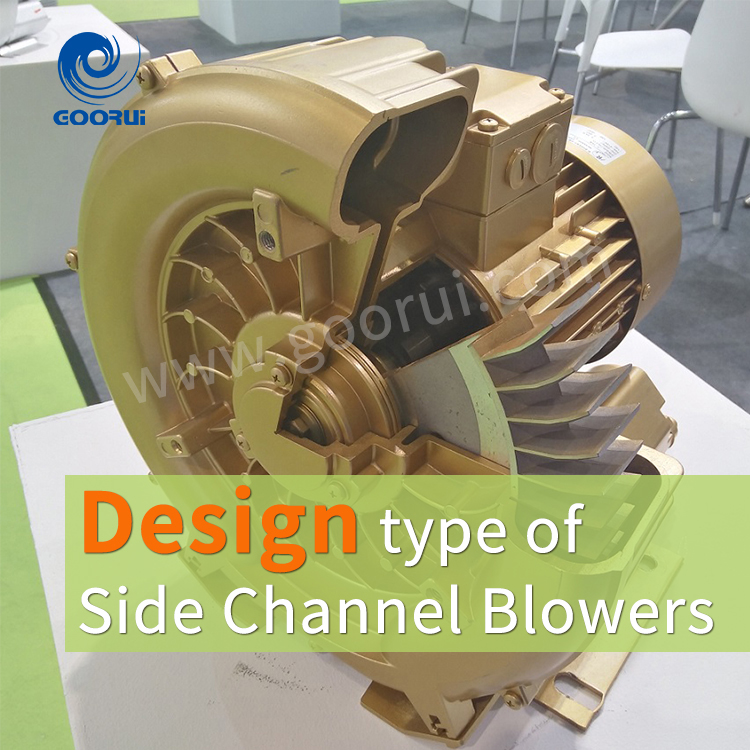

The high-pressure blower consists of dozens of blades that act like the impeller of a large gas turbine. This device places the air in the middle of the impeller blades, which is exposed to centrifugal force, and moves towards the edge of the impeller. As soon as the air enters the ring of the high-pressure blower body, its blade is rotated by a strong impeller inside the blower device and is pushed outwards and enters the system with airflow through a side channel of a very high energy air pump.

The advantages of the high-pressure blower

High-pressure blowers can be characterized as positive displacement, rotary machines used to move air or different gases. Their straightforward plan makes them low cost, and their non-contact design implies they have no wearing parts, so they are super dependable. The system is such that the bearings are outside the compression chamber so are shielded from the heat generated during compression. Accordingly, support is typically restricted to re-greasing the paths every 20,000 hours of running time (typical usage over 10–20 years).

High-pressure blowers, despite the structure and functional system mentioned, have found a good position among industries such as textiles, filtration, shallow wastewater treatment ponds, oxygen supply to aquaculture ponds, etc., which are popular. These industrial blowers are mainly due to the following advantages:

- Long shelf Life

- Low noise compared to other similar devices

- No need for lubrication and production of fresh air without pollution

- Low energy consumption and reduced costs

- Reasonable price and reduction of service and maintenance costs

GOORUI has a wide range of industrial blowers on offer. GOORUI blowers can generate turbo differential pressures up to 1000 mbar and airflows up to 2500 m³/h. There are affordable models in the product line that are not only easy to use but also very efficient. This point is because GOORUI is always trying to make the needs of its customer’s access to them. To receive advice, know the price list and order products, please contact GOORUI consultants and experts.