When it comes to air handling equipment, side channel blower has given this industry a new definition. The blower is used extensively in different industries including the chemical industry and heavy industry. Also known as the regenerative blower, it works on the principle of moving volumes of air through low pressure created on the vacuum. You may use this device in place of a vacuum pump if you want.

Wherever there is a need to remove smoke, dust, or carry out operations like vapor extraction from soil, sewage aeration, or lifting and packaging, side channel blower can be used comfortably. The main task of a regenerative blower is to deliver oil-free and clean air by subjecting it through a displacement technique. Well, the displacement technique to which the air is subjected to can be either positive or non-positive technique.

The unit or compact machine carries a positive displacement device to trap air and to channelize in the given direction. So, we can say that such a blower machine is just the replacement or substitute for the vacuum pump.

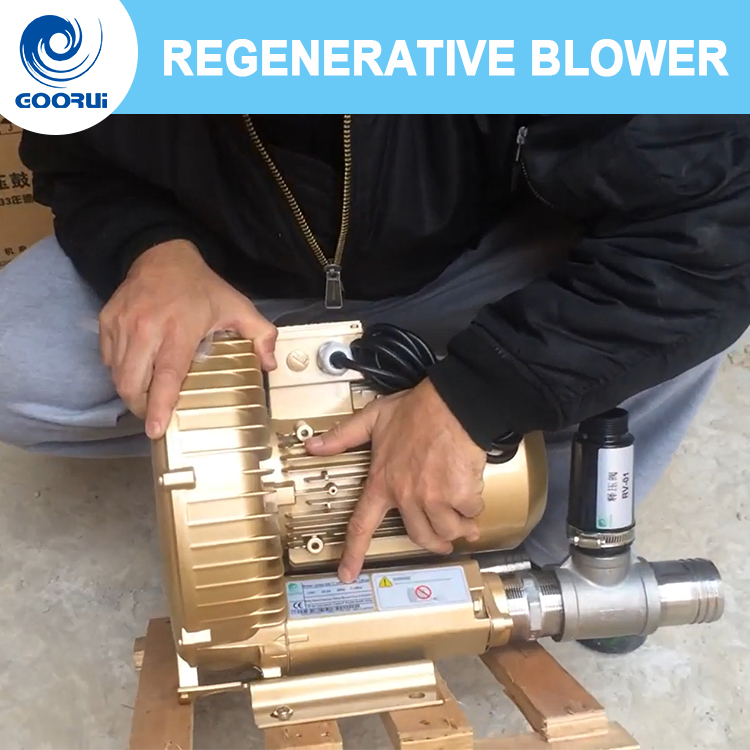

Side channel blower

A Side channel blower has the impeller which is driven or led by the electric motor. Carrying blades, the impeller moves around its perimeter or rotates inside the housing. Its main component is the inlet port through which the air enters. When the blades of the impeller move, it comes in contact with the air and this initiates centrifugal force to move air outwards and towards housing.

Henceforth, the compressed or pressurized air moves to the base of the blower housing. To repeat the same action again and again, the impeller moves multiple times. Finally, the compressed air gets discharged from the exhaust outlet.

There Are Various Benefits Of Using Side Channel Blower

The use of a side-channel blower can offer several advantages. They are:

-As the blower is designed in an efficient manner, there is minimum energy wastage in the process.

-The air that you get is clean and contaminant free. This is all due to the fact that it does not need any oil as the lubricant. There is no moisture content in the air or any compressor-induced impurity or contaminant.

-As the movement of the air inside the chamber is intense, a lot of heat is produced in the process. This heat may also be used for the drying process.

-They create the vacuum and this helps to hold the components and parts of the blower together.

-The machine is reliable and carries fewer moving parts. Thus, you do not need that much of part replacement.

-It is all due to the working system of the side channel blower that it benefits the engineers and users so much. There is no need for such maintenance or constant monitoring of the blower. Here the only moving part is the impeller that makes no contact with the blower housing channel. Hence, it is wear-free. The blower is oil-less and there is no need for any lubricant to keep the components moving. You may mount the blower on any of the surfaces and there will not be any noise.

The Installation Of The Blower Should Be Proper

Most of the blowers fail when there is poor installation or set up. The operator must know how to use it. Since the moving parts are less in number, there is less chance of components getting inactive. However, at least, the air passing must be smooth and efficient. If the air passing system is improper, it means that the machine is faulty.

A regenerative blower is used in several sectors for the advantages they offer. Some of the sectors include vacuum lifting and vacuum packing, printing press, spa, sewage aeration, etc. The side channel blower does not need any such maintenance and this is the greatest advantage.