The reasons for blowers getting hot & Solutions

1. Motor overload

If the blower motor carries too much load, it will cause the motor to be overloaded, which in turn generates a large amount of heat, resulting in the motor getting hot. At this time, you need to check whether the rated power of the motor and the load are matched, and if they are not matched, you need to replace the motor with a suitable one.

2. Damaged bearings

If the bearing of the blower motor is damaged, it will cause the motor to rotate poorly and generate a lot of friction heat, resulting in motor heating. At this point, you need to check whether the bearings are damaged, if so, they need to be replaced.

3. Winding failure

If the winding of the blower motor fails, it will lead to excessive current of the motor and generate a lot of heat, resulting in heating of the motor. At this time, you need to check whether the winding is damaged, if it is damaged, it needs to be repaired or replaced.

4. Unstable power supply voltage

If the power supply voltage of the blower motor is unstable, it will lead to unstable operation of the motor and generate a lot of heat, resulting in motor heating. At this time you need to check whether the power supply voltage is stable, if it is not stable, you need to adjust or replace the power supply.

5. In & out Air not smooth, too much resistance

If the blower’s in or air outlet not smooth, then the resistance of the blower will increase, the Current will also increase, then at this time the blower needs to do a higher function to do, indirectly, the temperature also rises. Simply put, that is, the higher the pressure when running, the temperature will also rise, the solution is to clean up the air inlet and outlet pipe, keep the pipe smooth, reduce losses.

6. Intake air temperature too high

Some customers have a high intake temperature, not the atmospheric temperature, such as is pumping steam and so on, then the intake temperature has been very high, plus the blower itself produces the temperature, hot is normal. Then we can only find ways to reduce the intake temperature.

7. Too low running voltage frequency

If the frequency too low, the rotational speed is reduced, the heat dissipation is not timely, will also make the high-pressure vortex blower hot hot, common is to use the frequency converter to adjust the blower frequency without paying attention to the heat dissipation.

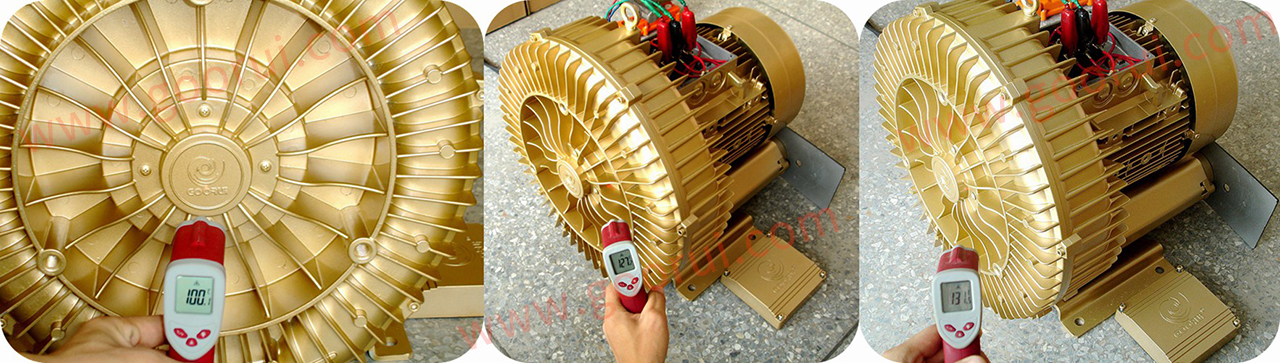

The solutions of heat reduce

There are many solutions to the hear of the blower, below listed a few common solutions:

1. Increase the heat dissipation area

The main reason for high pressure blower heat is poor heat dissipation, so you can increase the heat dissipation area to solve the heat problem. Can be installed in the high-pressure blower shell heat sink or radiator, increase the heat dissipation area, improve the heat dissipation effect.

2. Improve ventilation conditions

Poor ventilation is also one of the causes of high pressure blower heating, can improve ventilation to solve the heating problem. You can increase the number or size of vents, or increase the ventilation equipment around the high-pressure blower to improve the ventilation effect.

3. Reduce the load

Excessive load of blower is also one of the causes of heating, you can reduce the load to solve the heating problem. You can reduce the working time of the blower or increase the number of blowers , load sharing, reduce the load of a single blower.

4. Optimise the process flow

In some cases, blower is the cause of the process is unreasonable, you can optimise the process to solve the heat problem. You can adjust the process parameters or replace the process equipment, so that the process is more reasonable, reduce the load and heat of the blower .

In short, the blower motor heat and high pressure fan heat is a common problem in modern industry, but as long as we find the root cause of the problem, take the right solution, we can effectively solve these problems, improve the service life of the equipment and production efficiency!