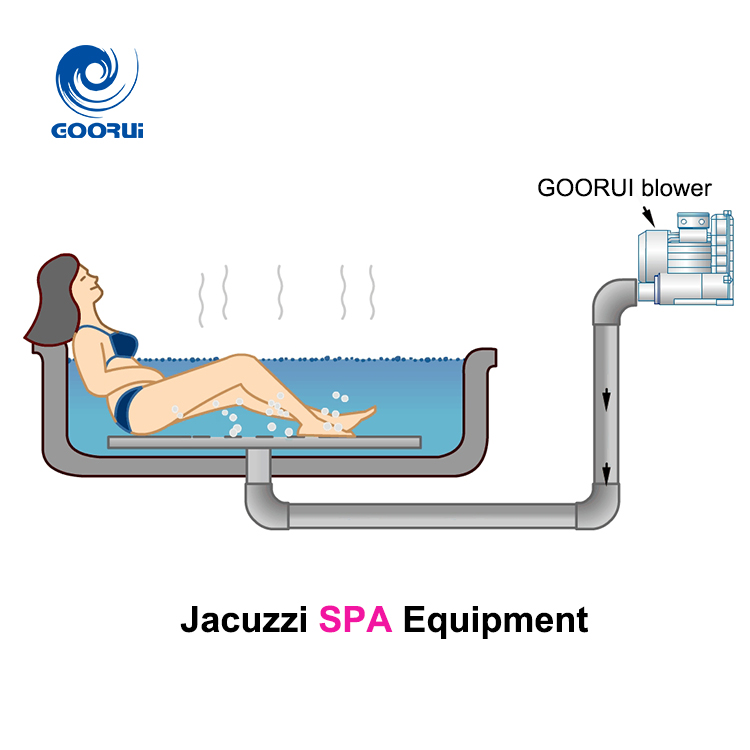

Ring blowers named as Side Channel Blowers, Regenerative Blowers, Vortex Blowers, they are suitable to all types of application which is necessary to move air, water, gas or materials (with vacuum or high pressure). Using them to help with such industrial activities as water treatment systems or sewage aeration, dust and smoke removal, vacuum systems vacuum lifting and packaging, printing equipment, aquaculture/pond aeration and soil vapor extraction etc.

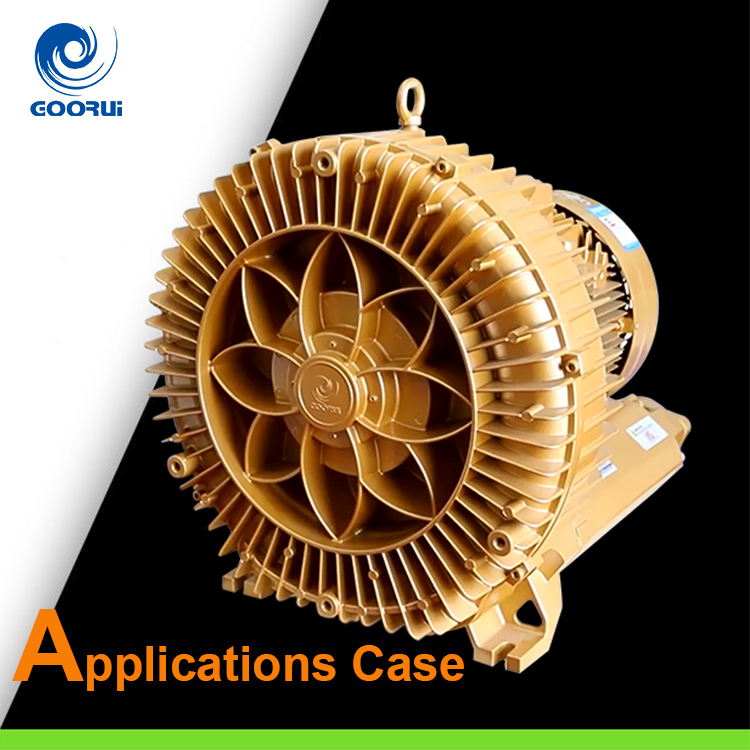

GOORUI manufactures three types of ring blower, they are available in single stage, double stage, three stage or multistage, and with motors single phase and three-phase. Normally, according to user’s application, and select the correct blower.

The ring blowers have several important advantages, which are easy to install, easy to use, long life and maintenance-fee, besides, comparing with centrifugal fans / blowers, the price of ring blowers are much economic.

Here we introduce the working principle of the ring blowers

The impeller of ring blowers are consist of many blades, it looks like a huge gas turbine impeller.

When the impeller rotates, due to the centrifugal force, the impeller would cause the gas to move forward in high speed. High-pressure blower thereby will form a series of spiral movements. The air between the impeller blades rotates in a spiral shape and squeezes the gas outside the pump body into the side channel (inhaled by the suction port). When the gas or air enter the side channel, it is compressed and then returned to the impeller blades again. And then speed up the rotation.

The air passes through the impeller and the side channel along a spiral track, each impeller blade increases the degree of compression and speed. As the rotation is continuing, the kinetic energy of the gas increases, causing the pressure of the gas passing along the side channel to further increase. When the air reaches the connection point between the side channel and the discharge flange, the gas is pushed out of the blade and the pump body through the outlet with high pressure and high speed to reach the final purpose.

The method of usage to blowers

During the high-pressure ring blowers running, the current consumed by the motor will increase with the increase of pressure and vacuum. If the current is too large, the contactor will trip off. In order to avoid tripping or to save power, please increase the cross-sectional area of the air outlet as possible as you can. Or install the adjustable valve of air pressure and air volume on the suction or exhaust side.

– In order to keep air supply, should install the appropriate filters at the entrance

1. The total cross-sectional area of the air outlet should be greater than 1/2 of the cross-sectional area of the fan outlet.

2. If use for air supply in water, the water depth pressure should be below 70% of the maximum static pressure value indicated on the model catalog.

3. When supplying air under pressure, the temperature of the outlet is normal due to the relationship of air friction greater than 10 degrees Celsius at room temperature. Therefore, should install an iron tube of more than 1m.

– Should install suction-silencers at the exit. And the total cross-sectional area of the suction hole should be greater than 1/2 of the cross-sectional area of the blower inlet.

– Simple filter cleaning method: Unscrew the filter adapter and use an air spray gun or brush to remove the dirt or dust on the filter. After cleaning, turn it back to use.