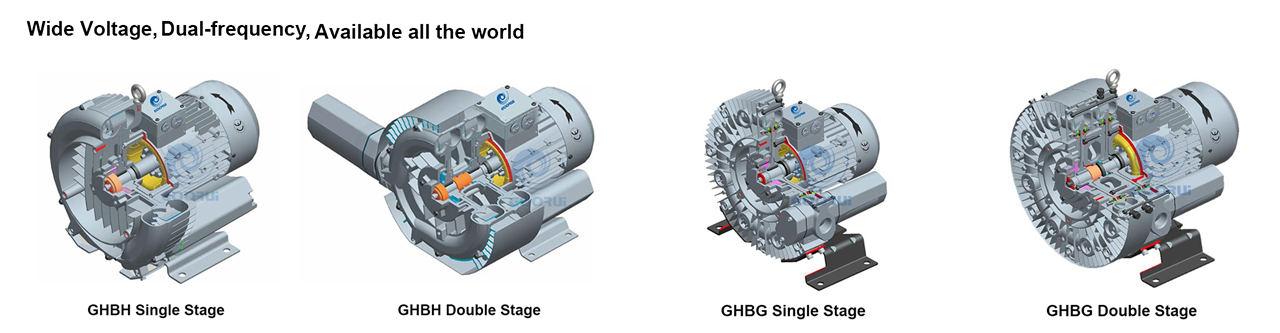

Goorui Regenerative Blowers, also known as Side Channel Blower, Ring Blower, Vortex Blower, Turbine Blower, Vacuum Pump, Ring Compressor are designed for all areas where pulsation-free vacuum and pressure services are required. Units may be installed horizontally or vertically. The die-cast Aluminium construction makes this a very robust product. Sealed-for-life bearings, a fan-cooled drive and a non-contact impeller all ensure that the regenerative blower are maintenance-free. Goorui regenerative blower are exceptionally environment-friendly, as they require no operating fluids. An internal silencer allows the regenerative blower to run very quietly, whilst the drive has energy-efficient motors. Special Anti-Corrosion blowers for highly corrosive environments & Anti-Explosion blowers for highly explosive environments are also available.

Choosing a high-pressure regenerative blower that suits you requires comprehensive consideration of many factors. Here are some suggestions:

1. Clarify the use requirements:

Functional requirements: Determine whether you need a blowing function or a suction function. If it is blowing, focus on the wind pressure of the blower; if it is suction, focus on the vacuum degree of the blower. For example, when aerating in sewage treatment, the blowing function of the high-pressure regenerative blower is mainly used; in scenarios such as industrial dust collection, the suction capacity is more important.

Usage scenario: Consider the use environment and application scenario of the blower. For example, in flammable and explosive environments such as petroleum and chemical industries, it is necessary to choose a high-pressure regenerative blower with explosion-proof performance; in situations with corrosive gases or liquids, a blower made of corrosion-resistant materials should be selected; if the use environment has strict requirements on noise, a low-noise blower should be selected.

2. Calculate the required parameters:

Air volume: Determine the air volume of the blower based on the gas flow required in the actual application scenario. This requires analysis and calculation of specific requirements such as gas transportation, ventilation and air exchange in the use scenario. If the air volume is insufficient, it may not meet the working requirements; if the air volume is too large, it will cause energy waste and increase equipment costs.

Wind pressure: Calculate the required wind pressure based on factors such as the distance of gas transmission, pipeline resistance, and resistance of the working object. Wind pressure is a key parameter to overcome pipeline resistance and working object resistance. Insufficient wind pressure will cause the gas to be unable to be transported normally or the working effect will be poor.

3. Evaluate the performance of the fan:

Efficiency: Selecting a fan with high efficiency can reduce energy consumption and reduce operating costs. When comparing high-pressure fans of different models, check their performance curves and efficiency parameters, and select fans with higher efficiency near the working point.

Speed: The speed will affect the fan’s performance such as air volume, air pressure, and noise. Generally speaking, the higher the speed, the greater the air volume and air pressure, but the noise will also increase accordingly. Select a fan with a suitable speed according to actual needs.

Reliability and stability: Understand the information on the fan’s manufacturing quality, structural design, and component quality, and select a fan with high reliability and stability. You can check the manufacturer’s production qualifications, product certification, user evaluation, and other information to evaluate the reliability of the fan.

4. Consider installation and maintenance:

Installation size and method: Choose a fan of appropriate size and installation method according to the space size and installation conditions of the use scenario. Ensure that the fan can be installed smoothly and will not affect the surrounding equipment and space.

Maintenance convenience: Choosing a fan that is easy to maintain can reduce maintenance costs and downtime. Understand the maintenance cycle, maintenance methods, required maintenance tools and other information of the fan, and choose a fan that is easy to maintain.

5. Choose the right brand and supplier:

Brand reputation: Choose a high-pressure regenerative blower from a well-known brand, and its product quality and after-sales service are more guaranteed. You can learn about the reputation and reputation of different brands through online searches, industry recommendations, user reviews, etc.

Supplier service: Choose a supplier with good after-sales service, who can provide technical support, maintenance services and spare parts supply in a timely manner. Communicate with the supplier before purchasing to understand its after-sales service policy and response speed.