When selecting a blower for industrial applications, it’s crucial to understand the differences between a centrifugal blower and a vortex blower. Both types of blowers serve unique purposes and are designed to operate in specific environments, making the correct choice essential for optimal performance and efficiency.

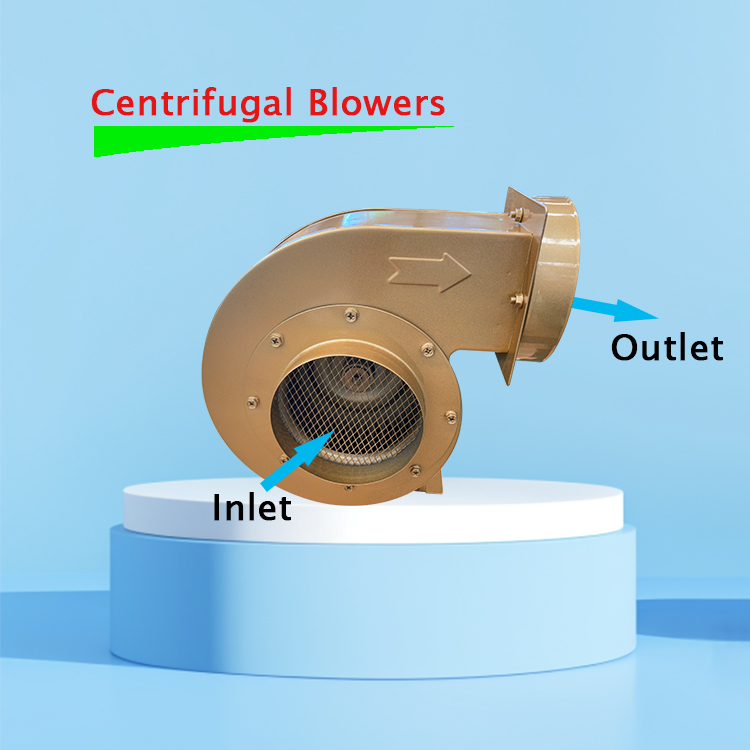

What is a Centrifugal Blower?

A centrifugal blower, also known as a radial blower, uses a rotating impeller to increase the velocity of air or gas, converting the kinetic energy into pressure. The air is drawn into the center of the impeller and then expelled outwards through the blades at high velocity. This type of blower is commonly used in air conditioning and refrigeration, fresh air systems, household appliances, air purification systems, automotive and office equipment, duct ventilation, clean rooms, engineering machinery, medical applications.

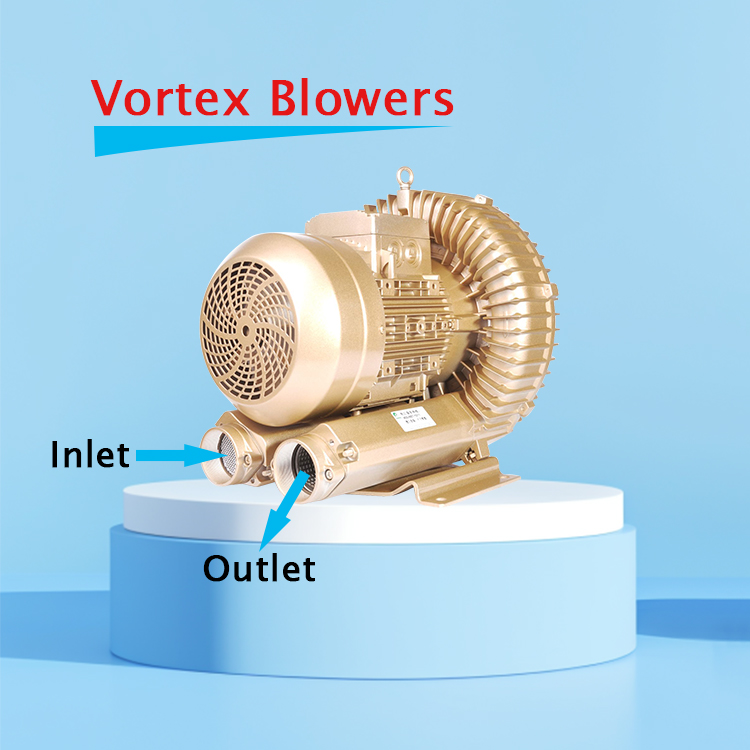

What is a Vortex Blower?

A vortex blower, also known as a regenerative blower, side channel blower, ring blower, operates differently from a centrifugal blower. It works by pulling air into the blower’s channel and using a rotating impeller to increase the pressure in small increments as the air circulates through the channel. This process allows the vortex blower to generate moderate pressure levels with high airflow rates.

Key Differences

Pressure and Airflow:

· Centrifugal Blower: Centrifugal blowers are typically more efficient at higher airflow rates and have relatively low pressure.

· Vortex Blower: Vortex blowers are often used in applications where a low air volume needs to be moved at high-pressure.

Application Suitability:

· Centrifugal Blower: For applications where high flow at low pressures is required.For example HVAC, ovens, tunnels, filter flushing, gas boosting, dust control, air conveyor systems, fluid bed aerators, etc.

· Vortex Blower: For applications where moderate flows with significant pressure are needed. For example Aquatics (spas and pools), pond aeration, vacuum evacuation of gases and dust, packaging, drying processes in wine production, pneumatic conveying, sewage aeration, etc.

Conclusion

Understanding these differences will help you select the most suitable blower for your industrial application, ensuring efficiency and longevity in your system. This knowledge of the differences between centrifugal and side channel blowers will assist you in making an informed decision that aligns with your operational requirements and optimizes performance.

GOORUI is a world-class manufacturer of premium vortex blowers and accessories with designing producing and marketing experience for 20 years , our programme of continuous investment and innovation places us at the forefront of blowers manufacture. To learn more, or if you have a specific application, send us an email with your requirements. Please be sure to include required Flow Rate and Pressure/Vacuum Requirements.

You can email us at: service@goorui.com