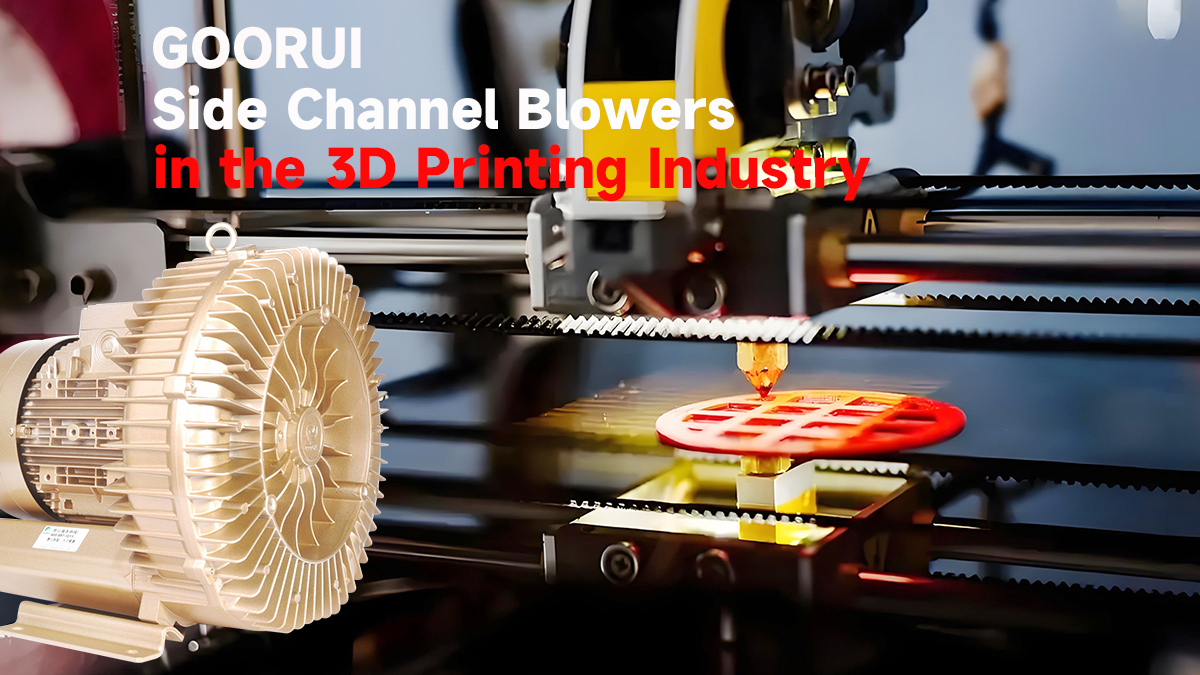

Side channel blowers, known for their high-pressure efficiency and compact design, play a critical role in supporting various processes within the 3D printing industry. Below are key applications where these blowers are utilized:

1. Cooling and Thermal Management

· Rapid Cooling of Printed Layers: Side channel blowers are used to accelerate the cooling of 3D-printed layers, particularly in high-speed printing processes. This ensures dimensional stability and reduces warping in materials like polymers and metals.

· Temperature Control in Enclosed Chambers: For industrial-grade 3D printers operating in controlled environments, blowers maintain consistent airflow to regulate temperature, preventing overheating during prolonged printing sessions.

2. Powder Handling and Recycling

· Removing Excess Powder: In powder-based 3D printing technologies (e.g., selective laser sintering), side channel blowers generate airflow to remove excess powder from printed parts, improving surface finish and reducing material waste.

· Powder Conveyance Systems: These blowers facilitate the transport of powdered materials (e.g., metal or polymer powders) through pneumatic systems, ensuring efficient supply to the printing bed.

3. Vacuum and Fume Extraction

· Eliminating Harmful Emissions: During printing with resins or high-temperature materials, side channel blowers are integrated into fume extraction systems to remove volatile organic compounds (VOCs) and particulates, ensuring workplace safety.

· Vacuum Bed Adhesion: Some 3D printers use vacuum systems to secure printing substrates. Side channel blowers provide the necessary vacuum pressure to hold materials in place, enhancing print accuracy.

4. Post-Processing Support

· Cleaning and Surface Finishing: Post-printing, blowers assist in cleaning residual debris from printed parts using high-velocity air streams. This is critical for applications requiring high precision, such as aerospace or medical devices.

· Drying and Curing: In resin-based 3D printing, side channel blowers aid in accelerating the drying or UV-curing processes by maintaining controlled airflow around the components.

5. Automation and Material Handling

· Automated Conveyor Systems: Integrated with robotic arms, side channel blowers enable automated material handling, such as transferring printed parts between stages or removing support structures.

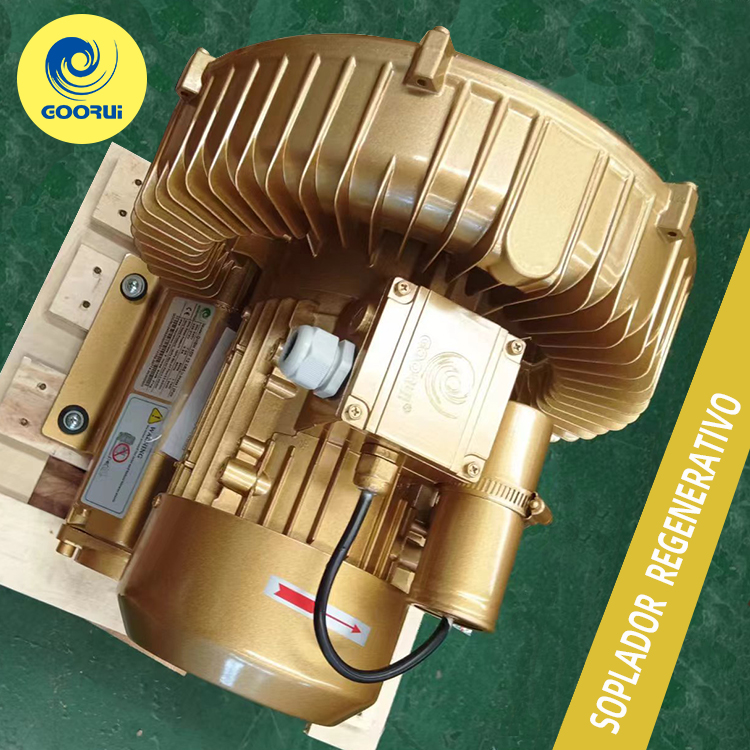

· Technical Advantages of Side Channel Blowers

· Energy Efficiency: Their design minimizes energy consumption while delivering high airflow rates (up to 2,480 m/h) and pressure ranges (-500 mbar to 98,000 Pa), making them ideal for continuous industrial operations.

· Low Noise and Vibration: Advanced balancing of impellers ensures quiet operation, crucial for lab and factory environments.

For detailed specifications contact GOORUI.