Regenerative blowers are widely used in the food industry. Their core value lies in high efficiency, hygiene, and energy saving, which can meet the stringent requirements of food processing for cleanliness, safety, and production efficiency.

I. Core application scenarios

1. Pneumatic conveying system

Applicable materials: powder (flour, milk powder, additives), granules (sugar, grains, coffee beans), flakes (potato chips, dried fruits).

Advantages: avoid mechanical contact pollution, reduce material breakage, and are suitable for long-distance, closed transportation.

Case: cocoa powder transportation in chocolate production, flour feeding in biscuit production.

2. Drying and cooling

Drying: spray drying (milk powder, protein powder), hot air drying (dried fruits and vegetables, meat products).

Cooling: rapid cooling of baked foods (bread, biscuits) after they are out of the oven to prevent deterioration.

Technical requirements: precise control of wind temperature (high temperature resistant blower) and wind speed to avoid damage to food quality.

3. Cleaning and drying

CIP (cleaning in place) system: use high-pressure airflow to remove pipe residues.

Packaging: drying before filling bottled beverages (such as PET bottles), dust removal before can capping.

4. Vacuum packaging and controlled atmosphere preservation

Vacuum pump matching: extract air from the package to extend the shelf life (such as cooked food, cheese).

Controlled atmosphere preservation: inject nitrogen/CO₂ mixed gas to inhibit microorganisms (fresh-cut fruits and vegetables, pre-prepared dishes).

5. Waste gas and odor treatment

Oil fume emission: oil fume collection in fried and grilled food processing.

Odor control: exhaust gas extraction in fermentation workshops (soy sauce, wine).

II. Technical requirements for food-grade regenerative blowers

1. Material safety

Contact parts: 304/316 stainless steel, in line with FDA and EU 1935/2004 standards.

Sealing material: food-grade silicone or EPDM rubber, corrosion-resistant and non-toxic.

2. Hygienic design

Structure without dead corners: easy to disassemble and clean to avoid bacterial growth (such as IP69K protection level).

Surface treatment: polishing or antibacterial coating (such as Ag+ ion coating).

3. Performance adaptation

Explosion-proof requirements: ATEX certification is required when handling flammable materials such as alcohol and flour.

Low noise: workshop environment requirements (usually ≤75dB).

4. Energy efficiency standards

IE3/IE4 high-efficiency motors: reduce long-term energy consumption costs.

Frequency control: adjust air volume according to load (such as intermittent operation of conveying system).

III. Market driving factors

1. Upgrade of food safety regulations

For example, China’s GB 14881-2013 mandatory requirements for the cleanliness of food equipment promote the replacement of old equipment.

2. Explosion of pre-prepared meals and convenience foods

In 2023, the scale of China’s pre-prepared food market will reach 500 billion yuan, driving the demand for blowers in the drying and packaging links.

3. Automation and intelligent transformation

Food factories reduce manual intervention, and regenerative blowers become key components of pneumatic automation systems.

4. Sustainable development pressure

Energy-saving blowers can reduce carbon emissions.

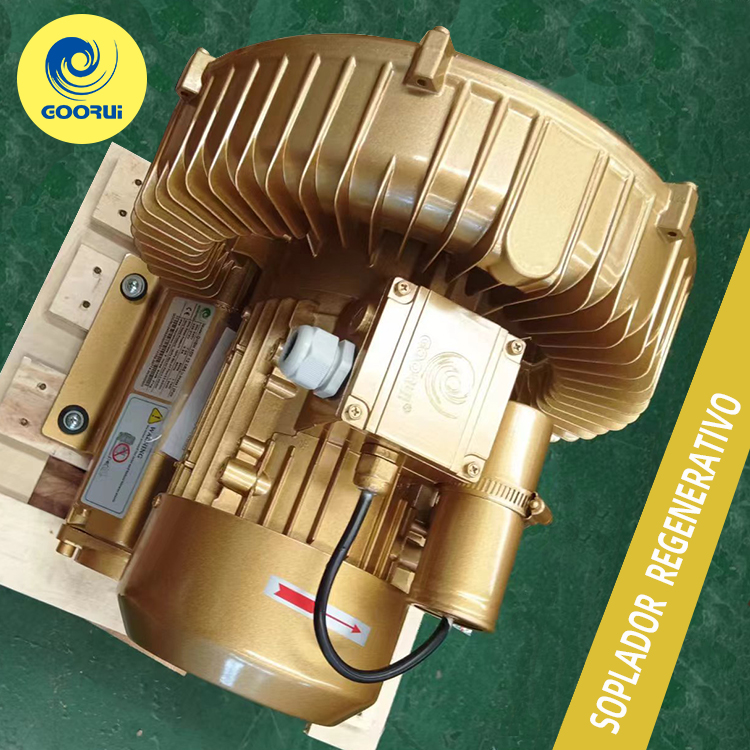

If your business depends on quality performance from air technology equipment, then come and talk to GOORUI to find out more about our air technology services and solutions.