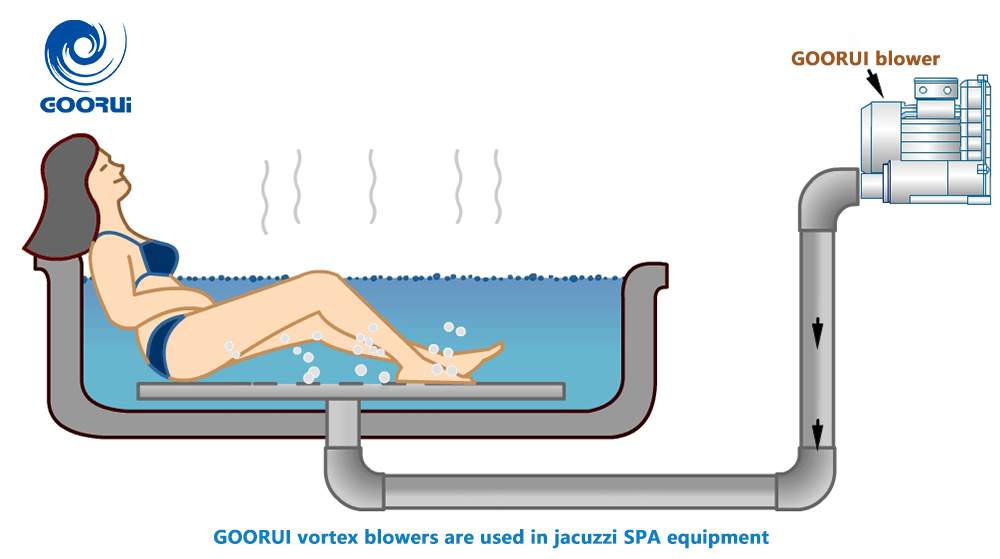

The application of vortex blowers (also known as vortex air pumps and side channel blowers) in jacuzzi SPA equipment mainly relies on their high-pressure airflow, low noise, energy-saving and high-efficiency characteristics. They are often used in hot spring pool aeration, water circulation, massage and other scenarios.

Common application scenarios

(1) Hot spring aeration and oxygenation

Function: Inject air into hot spring water through vortex blowers to increase dissolved oxygen in the water, improve water quality, and inhibit the growth of anaerobic bacteria.

Advantages: Compared with ordinary air pumps, vortex blowers provide more stable airflow and higher pressure (especially suitable for aeration in deep water areas).

(2) Massage bubble system

Function: Provide high-pressure airflow for hot spring massage pools (such as bubble baths and reclining chair massage holes) to generate dense bubbles and enhance comfort.

Design points: It needs to be used with air stones or diffusers, and the fan pressure needs to be selected according to the water depth (for example, a water depth of 1 meter requires at least 10kPa pressure).

(3) Water circulation assistance

Function: Cooperate with the water pump to promote the flow of water through airflow to avoid uneven temperature or dead water in the hot spring.

(4) Ozone mixing system

Function: Some hot spring equipment will use vortex fans to inject ozone (O₃) into the water for sterilization. A fan made of corrosion-resistant material (such as stainless steel) must be selected.

Installation and maintenance precautions

Installation position: Above the water surface (to prevent backflow), or install a check valve; away from the area directly in contact with the hot spring moisture.

Pipeline design: Use high temperature and corrosion resistant PVC or silicone tubes to avoid right-angle elbows to reduce pressure loss.

Maintenance:

1. Clean the air intake filter regularly (to avoid sulfide or scale blockage).

2. Check the lubrication of the motor bearing (the hot spring environment can easily accelerate the rust of metal parts).

3. Empty the water in the pipe when it is not used for a long time.

Common problem solving

Problem 1: Insufficient airflow

→ Check whether the pipeline is leaking or blocked, and confirm whether the fan pressure matches the water depth.

Problem 2: Fan overheating

→ It may be due to continuous operation or inhalation of high temperature moisture. It is necessary to increase heat dissipation or switch to a high temperature resistant model.

Problem 3: Abnormal noise

→ Check whether the impeller is worn (hot spring moisture may accelerate corrosion).