Vortex blowers (also known as ring blowers or regenerative blowers) play an important role in environmental waste sorting systems. They mainly use their strong wind force and negative pressure suction to achieve key links such as waste transportation, sorting, and dust removal. The following is an analysis of its specific applications and advantages:

Main application scenarios

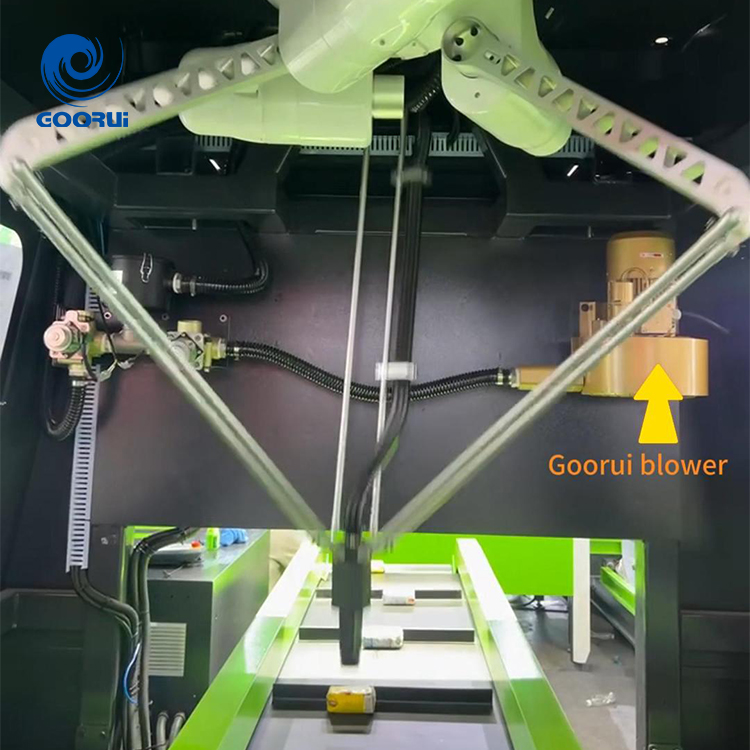

(1) Airflow sorting (wind sorting)

Principle: Utilize the density difference of different components in the waste (such as plastic, paper, metal, etc.) to separate light materials (such as plastic film, foam) from heavy materials (metal, glass) through the airflow generated by the vortex blower.

Advantages: No need for water washing, reduce secondary pollution, suitable for dry sorting.

(2) Negative pressure adsorption and transportation

Material collection: The scattered garbage (such as crushed light plastic and fiber) is sucked into the sorting pipeline through the negative pressure suction nozzle and concentrated to the designated location.

Anti-blocking: High-pressure airflow can prevent pipeline blockage and is suitable for long-distance transportation.

(3) Dust removal system

Dust suppression: In the crushing and screening process, the blower cooperates with dust removal equipment (such as cyclone separator, bag filter) to absorb dust and improve the working environment.

(4) Vibrating screen auxiliary

Auxiliary screening: Blow air under the vibrating screen to help light materials (such as plastic bags) float up and improve screening efficiency.

Advantages of vortex blowers

·High air pressure/suction: Suitable for handling loose and light garbage (such as PET bottles and packaging bags).

·Oil-free operation: Avoid lubricating oil contamination of garbage, meet environmental protection requirements.

·Compact structure: Easy to integrate into automated sorting lines.

·Low maintenance: No internal mechanical friction, suitable for long-term continuous operation.

Actual case reference

·Plastic sorting: In the waste plastic recycling line, the blower blows the crushed plastic pieces to different heights and sorts them through sensors (such as near-infrared sorting machine to identify materials).

·Paper sorting: Air flow separates paper and impurities (such as staples and sand).

·RDF (Refuse Derived Fuel) Preparation: Sorting out combustibles (such as wood chips, textiles) for energy utilization.

Selection considerations

·Air volume and air pressure: Select according to garbage density and conveying distance (such as lower air pressure for plastic sorting, higher suction for metal chips).

·Corrosion resistance: Stainless steel or anti-corrosion coating is required when handling wet garbage.

·Noise control: Install a muffler to meet environmental standards.

Supporting equipment recommendations

·Cyclone separator: Cooperate with the blower to achieve gas-solid separation.

·Intelligent sorting machine: Combine AI vision or sensors to improve sorting accuracy.

·Frequency conversion control: Adjust air volume to adapt to different types of garbage.

Summary

The vortex blower significantly improves the sorting efficiency and automation level through efficient and clean airflow control in garbage sorting, especially for the refined sorting of recyclables (plastics, paper). Reasonable selection and system integration can reduce energy consumption and help achieve the goal of reducing and recycling garbage sorting.