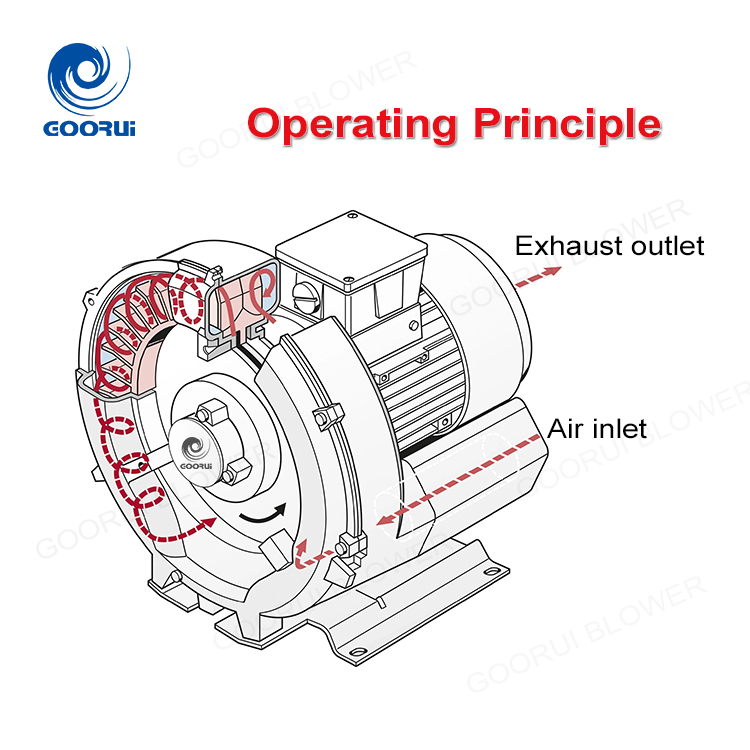

Regenerative blowers use a rotating impeller to accelerate air around a channel (or side channel) within the blower housing. This process regenerates the airflow multiple times, increasing the pressure and airflow.

Single-stage and two-stage regenerative blowers differ primarily in how they handle airflow to create pressure. Single-stage blowers pass air through the impeller once, while two-stage blowers redirect the air for a second pass, resulting in higher pressure and vacuum capabilities.

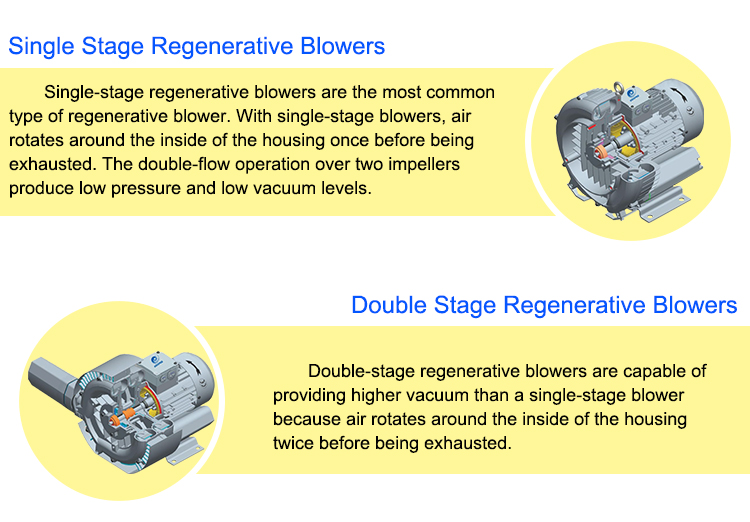

Single-Stage Regenerative Blowers:

Function:

Air flows through the blower housing and impeller only once before being exhausted.

Pressure/Vacuum:

Offer moderate pressure and vacuum levels, but generally lower than two-stage.

Flow Rate:

Typically provide higher flow rates compared to two-stage blowers.

Applications:

Well-suited for applications where air volume is more important than high pressure, such as aeration, pneumatic conveying, and some industrial processes.

Two-Stage Regenerative Blowers:

Function:

Air is channeled back around the impeller for a second rotation before being exhausted.

Pressure/Vacuum:

Deliver significantly higher pressure and vacuum capabilities.

Flow Rate:

Offer lower flow rates compared to single-stage blowers for the same size and power.

Applications:

Ideal for applications requiring higher pressure or vacuum, such as certain types of industrial equipment, medical devices, and some cleaning systems.

In essence:

·Single-stage: More flow, moderate pressure.

·Two-stage: Higher pressure and vacuum, but lower flow.

The choice between single-stage and two-stage regenerative blowers depends on the specific requirements of the application, with higher pressure needs favoring two-stage and higher volume needs favoring single-stage.