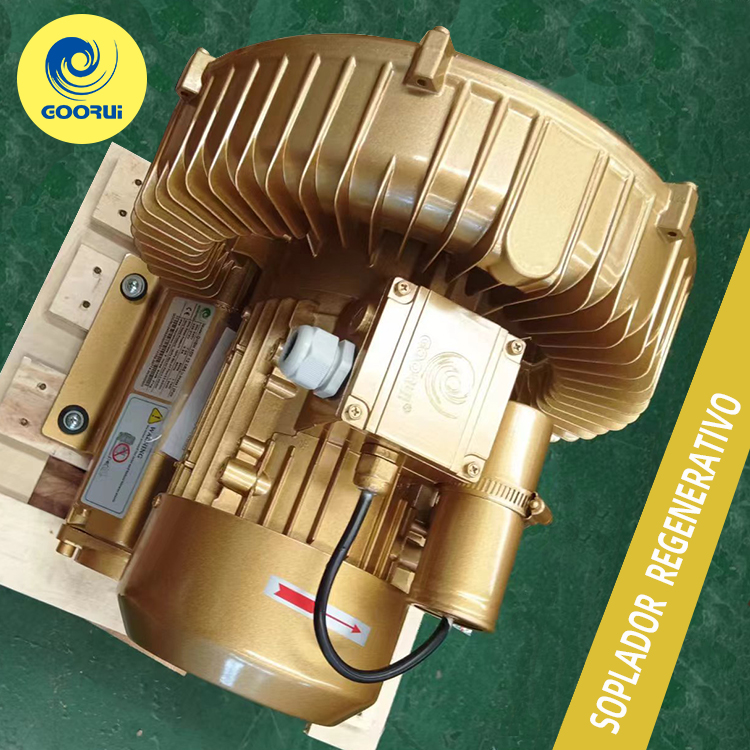

With their core characteristics of high pressure, large flow, clean, oil-free operation, and stable operation, high-pressure regenerative blowers perfectly meet the photovoltaic industry’s stringent requirements for process cleanliness, production stability, and product yield. They have deeply penetrated the entire photovoltaic module production process (silicon material → silicon wafer → cell → module). The main application scenarios can be broken down by production stage as follows:

I. Compatibility of Core Characteristics with Photovoltaic Industry Needs

Before deploying applications, it is important to first understand how the core advantages of high-pressure regenerative blowers align with photovoltaic production needs:

–Clean and oil-free: Photovoltaic silicon material, wafers, and cells are extremely sensitive to impurities (such as oil and dust). The slightest contamination can lead to reduced conversion efficiency or product rejection. The oil-free design ensures absolutely clean airflow.

–Stable pressure: Pneumatic conveying, vacuum adsorption, and drying and curing in photovoltaic production require constant pressure/negative pressure to prevent pressure fluctuations that can cause material blockage, workpiece dropout, or uneven drying.

–Adjustable flow: Variable frequency control can be used to adapt to different sizes (e.g., High-pressure blowers are used to meet the process requirements of 166mm, 182mm, and 210mm silicon wafers/modules, balancing efficiency and energy consumption.

– Low noise + long life: PV factories are mostly operated continuously (24/7). Low noise improves the workshop environment, while long life reduces the impact of maintenance downtime on production capacity.

II. Specific Application Scenarios by PV Production Process

PV production is divided into four core stages: silicon material preparation, silicon wafer processing, cell manufacturing, and module packaging. The application of high-pressure regenerative blowers focuses on each stage:

1. Silicon Material Preparation: Pneumatic Conveying and Pollution Prevention

Silicon material (polycrystalline silicon granules) is the raw material for PV production. It needs to be transported from the silo to the single crystal/multi-crystallization furnace for melting and drawing. The core requirements of this stage are “sealed conveying and contamination prevention.” Application Scenario: Pneumatic Conveying of Silicon Ingots

A high-pressure regenerative blower provides clean, positive air pressure of 0.05-0.2 MPa, pushing silicon ingots through a closed pipeline (pneumatic conveying), achieving contactless conveying from the silo to the furnace inlet.

· It prevents silicon ingots from coming into contact with air and dust, preventing the incorporation of impurities (such as metal ions) that could affect the purity of the ingots.

· Stable pressure allows for precise control of the conveying rate (e.g., 100-500 kg/h), preventing pipeline blockages or uneven feeding that could lead to furnace temperature fluctuations.

2. Silicon Wafer Processing: Cleaning, Drying, and Damage-Free Handling

Silicon wafers are the core substrate of photovoltaic modules. The processing process involves ingot cutting, wafer cleaning, and wafer sorting. This process requires addressing the issues of removing residue and preventing scratches.

Application Scenario: Drying Silicon Wafers After Cleaning

After slicing, residual cutting fluid (such as PEG-based coolant) remains on the surface of silicon wafers and requires cleaning before drying.

A high-pressure blower drives the air knife system, generating clean, dry air at a high velocity (30-50 m/s) that evenly blows across the front and back of the wafer, completely removing moisture within 1-2 seconds. This prevents residual water stains that could cause uneven surfaces and affect subsequent coating.

Application Scenario: Vacuum Handling of Silicon Wafers

Silicon wafers are only 160-200 μm thick (as thin as paper), and mechanical gripping can easily cause cracking and scratching.

The high-pressure regenerative blower generates a stable negative pressure (-0.06 to -0.08 MPa) through a vacuum generator, enabling the robotic gripper to firmly grasp the wafer, enabling non-destructive handling from the cleaning machine to the sorting machine to the temporary storage rack. This is particularly suitable for large 210 mm wafers.

3. Cell Manufacturing: Process Assistance and Quality Assurance

Cells are the “power generation core” of photovoltaic modules and undergo a series of precision processes, including texturing, diffusion, etching, PECVD coating, screen printing, and drying and curing. High-pressure regenerative blowers primarily serve the “pre-coating pretreatment and post-printing drying” phases.

Scenario 1: Plasma Cleaning Assistance Before PECVD Coating

PECVD (plasma-enhanced chemical vapor deposition) is a key process for depositing anti-reflective coatings (such as SiNx and Al2O3) on silicon wafers. Before coating, trace oil and oxide layers on the wafer surface must be removed (otherwise, the film has poor adhesion and is prone to detachment).

High-pressure regenerative blowers deliver clean compressed air into the plasma cleaner, where it mixes with process gases (such as Ar and O2) to generate plasma. The airflow disturbance ensures that the plasma is evenly applied to the wafer surface, enhancing cleaning effectiveness.

Scenario 2: Post-screen Printing Paste Drying

The solar cell requires printing silver paste (for the front electrode) and aluminum paste (for the back electrode). The printed paste needs to dry and solidify quickly to prevent diffusion and deformation of the electrode pattern.

A high-pressure regenerative blower, serving as the power source for the hot air drying oven, evenly delivers clean air heated to 80-120°C into the oven. By controlling the airflow velocity (1-3 m/s) and temperature stability (±2°C), the paste is ensured to dry evenly and solidify tightly, improving electrode conductivity (which directly impacts the cell conversion efficiency).

4. PV Module Encapsulation: Glass Cleaning and Sealing Testing

Module encapsulation is the process of assembling the glass, EVA film, solar cell, backsheet, and aluminum frame into a finished product. Key requirements include strong bonding and a waterproof seal.

Scenario 1: Cleaning and Drying Module Glass

The cover glass serves as the module’s protective layer. Dust and oil on the surface can weaken the adhesion between the EVA film and the glass (prone to delamination during long-term outdoor use).

A high-pressure regenerative blower drives multiple air knives to perform high-pressure drying on the cleaned glass surface, ensuring a surface cleanliness level of “≤5 particles larger than 0.5μm per square meter,” laying the foundation for the subsequent lamination process (bonding the glass to the EVA film).

Scenario 2: Module Sealing Performance Test

PV modules must pass IP67/IP68 waterproof testing (for outdoor use and protection against rainwater intrusion). This test relies on the positive/negative pressure control of a high-pressure regenerative blower:

a. The module is placed in a sealed chamber, and a high-pressure regenerative blower pumps clean air into the chamber (positive pressure test, 0.02-0.05 MPa).

b. After shutting off the air supply, a pressure sensor monitors the pressure change over 30 minutes. If the pressure drops by ≤5%, the seal is considered leak-free.

c. If the seal fails, leaks in the frame rubber strips, junction boxes, and other areas can be quickly located to prevent short circuits caused by water ingress during outdoor use.

III. Extended Applications: Key Selection Considerations

When selecting a high-pressure regenerative blower for the photovoltaic industry, focus on the following three points to avoid production disruptions due to equipment compatibility issues:

Cleanliness Level: For airflow that comes into direct contact with silicon wafers, solar cells, and glass, select an oil-free vortex or screw-type high-pressure blower, ensuring an oil content of ≤0.01 mg/m³.

Corrosion Resistance: Cell etching and PECVD processes may expose cells to trace amounts of corrosive gases (such as HF and NH3). Therefore, select a blower with a stainless steel core or anti-corrosion coating.

Variable Frequency Function: The process parameters for large-sized modules (such as 182mm and 210mm) differ significantly from those for smaller modules. Variable frequency high-pressure blowers can adjust their speed to meet varying flow/pressure requirements, reducing energy consumption (saving 15%-30% compared to fixed frequency models).

Summary

High-pressure regenerative blowers are common process auxiliary equipment in photovoltaic production. From preventing contamination at the source during silicon material transportation to ensuring lossless handling of silicon wafers and cells, and ensuring the sealing of modules, their stability and cleanliness directly impact the conversion efficiency, yield, and service life of photovoltaic products. As the photovoltaic industry evolves toward larger sizes, higher efficiencies, and increased cost savings, high-pressure regenerative blowers are also evolving toward higher pressure, greater flow rates, and lower energy consumption. If your business depends on quality performance from air technology equipment, then come and talk to GOORUI to find out more about our air technology services and solutions.