High-pressure regenerative blowers (sopladores regenerativos) are a key piece of equipment in aquaculture, especially high-density, intensive farming. Their core function is to oxygenate and improve water quality through forced air flow, directly impacting the survival rate, growth rate, and overall profitability of farmed animals. The following article comprehensively analyzes high-pressure fans in aquaculture, focusing on their functions, principles, applicable scenarios, key selection criteria, and precautions.

Core Functions: Why are high-pressure fans essential for aquaculture?

The functions of high-pressure fans revolve around two key areas: “maintaining dissolved oxygen” and “optimizing water quality.” They can be categorized into three types:

Water Oxygenation (Core Function)

Aquacultured animals (fish, shrimp, crabs, and shellfish, among others) breathe dissolved oxygen (DO) in the water through their gills. When DO falls below a critical value (e.g., fish typically require ≥3 mg/L, shrimp ≥5 mg/L), they will float, stop feeding, and even suffer widespread mortality.

High-pressure blowers deliver high-pressure air into the water, which is then converted into tiny bubbles by aeration devices (such as aeration discs, aeration tubes, and nanotubes). As the bubbles rise, they fully interact with the water, significantly increasing DO efficiency (more uniformly and at a deeper depth than traditional waterwheel-type aerators).

Water Quality Improvement (Auxiliary Function)

Aeration: High-pressure airflow promotes upward and downward circulation of water, breaking down water stratification (such as the thermocline in a pond in summer) and preventing “pond flooding” caused by hypoxia in the bottom water.

Decomposition of Harmful Substances: Sufficient dissolved oxygen promotes the activity of beneficial bacteria (such as nitrifying bacteria), accelerating the decomposition of toxic substances such as ammonia nitrogen, nitrite, and hydrogen sulfide, thereby reducing the risk of water pollution.

Suitable for Special Scenarios

For applications such as factory-scale recirculating aquaculture (RAS), fish and shrimp nursery ponds, and deep-water cages, continuous and stable oxygenation is required. High-pressure blowers can be used in conjunction with the circulation system to achieve an integrated “oxygen supply and water purification” solution.

Working Principle: How do high-pressure blowers achieve efficient oxygenation?

High-pressure blowers used in aquaculture are mostly positive displacement blowers (such as vortex high-pressure blowers and Roots blowers). Their working process can be simplified into three steps:

1. Intake Phase: The motor drives the impeller/rotor to rotate, creating a negative pressure inside the blower housing and drawing air in from the outside (impurities must be filtered to prevent clogging of the aeration system).

2. Compression Phase: The impeller/rotor compresses the air through volume changes (such as the centrifugal force of a vortex blower or the meshing of the rotors of a Roots blower), generating a high-pressure airflow of 0.01-0.15 MPa (the pressure must match the aquaculture water depth and pipe resistance).

3. Aeration and Dissolved Oxygen: The high-pressure airflow is transported through PVC/PE pipes to the underwater aeration system, where it is converted into tiny bubbles with a diameter of 0.1-1 mm (the smaller the bubbles, the greater the contact area with the water, and the higher the oxygen dissolution efficiency), ultimately dissolving oxygen.

Applicable Scenarios: Which farming methods require high-pressure blowers?

High-pressure blowers aren’t required in all farming scenarios. They are more suitable for farming methods with high oxygen consumption and high density, including:

| Breeding model | Adaptation reasons |

| Industrial recirculating aquaculture (RAS) | Closed water bodies and high density (such as 50-100 fish per cubic meter) require 24-hour stable oxygenation and aeration in conjunction with biological filters. |

| Pond high-level pond aquaculture | Intensive shrimp/fish farming (e.g., high-level ponds for whiteleg shrimp) with a water depth of 2-4 meters (traditional aerators cannot reach the bottom layer) requires bottom aeration to prevent hypoxia. |

| Fish and shrimp nursery | Seedlings are sensitive to dissolved oxygen (requires ≥6 mg/L), and the water body is shallow and the density is high, so uniform oxygenation is required to avoid local hypoxia. |

| Deep water cage aquaculture | The water depth is 5-15 meters. Traditional aerators are inefficient. High-pressure fans combined with deep-water aeration plates can achieve bottom-level oxygenation. |

| Benthic aquaculture (such as crabs and shellfish) | Benthic animals (such as blue crabs and clams) require sufficient dissolved oxygen in the bottom layer. High-pressure fans can improve the bottom environment and reduce diseases. |

Selection Tips: How to Choose the Right High-Pressure Blower for Your Application?

Incorrect selection can result in insufficient oxygen enrichment or excessive energy consumption. Pay special attention to the following five parameters:

Calculating “Oxygen Demand”: Determine Blower Flowrate

Oxygen demand (m³/h) = aquaculture water volume (m³) × dissolved oxygen demand coefficient (depending on the species).

For example, a 100m³ whiteleg shrimp nursery pond (with a density of 100,000 shrimp/mu) requires approximately 15-20m³/h of oxygen. Therefore, a fan with a flowrate of ≥20m³/h should be selected.

Note: A 20% margin of flowrate is required to account for sudden weather changes, increased oxygen consumption after feeding, and other factors.

Matching “Water Depth and Pipeline”: Determining Blower Pressure

The blower pressure (kPa) must overcome “water depth pressure” + “pipeline resistance”:

Water depth pressure: 1 meter water depth ≈ 10 kPa (e.g., 3 meters water depth requires 30 kPa pressure);

Pipeline resistance: Calculate based on pipeline length (approximately 5 kPa per 10 meters) and the number of elbows (approximately 2 kPa per elbow).

Example: 3 meters water depth + 20 meters pipeline + 2 elbows: Required pressure = 30 + 10 + 4 = 44 kPa. Select a fan with a pressure ≥ 50 kPa (allowing 10% margin).

Select materials based on water quality.

Aquaculture environments are humid and saline, requiring corrosion protection:

For ordinary ponds: Choose a “cast iron housing + stainless steel impeller”;

For marine aquaculture/factory RAS: Choose an “all-stainless steel housing” (to prevent salt corrosion).

Focus on “Energy Consumption and Noise”: Choose an energy-efficient blower.

Energy Consumption: Prefer variable-frequency high-pressure fans (which adjust speed in real time based on dissolved oxygen, saving over 30% energy compared to fixed-frequency fans).

Noise: For factory farms or near residential areas, choose a fan with a noise level of 75dB or less (preferably with a silencer).

Compatible with “Aeration Devices”

If using nano-aerators (small bubbles, high dissolved oxygen efficiency), fan pressure must be ≥ 50 kPa (nanotubes have greater resistance).

If using standard aeration tubes, pressure ≥ 30 kPa is sufficient.

Usage and maintenance precautions: Extend life + ensure safety

Installation Specifications

The fan must be installed in a well-ventilated, dry room (to avoid rain damage) and on a flat surface to reduce vibration and noise.

The air inlet must be equipped with an “air filter” (to filter dust and insects and prevent clogging of the aeration system).

Pipe connections must be sealed (using silicone sealing rings to prevent air leaks that could reduce oxygenation efficiency).

Operation Management

Avoid frequent starts and stops: excessive current during starts and stops can damage the motor; sudden changes in dissolved oxygen can also stress the animals.

Real-time dissolved oxygen monitoring: Use a dissolved oxygen meter. When dissolved oxygen is ≥8 mg/L, reduce the fan speed appropriately; when it is ≤5 mg/L, increase the fan speed (for variable frequency fans).

On rainy/hot days: Start the fan early (to avoid sudden drops in dissolved oxygen at night, which can cause floating heads).

Daily Maintenance

Clean the air filter (to prevent clogging that could reduce airflow);

Check the engine oil level (Roots blowers require regular oil changes, while vortex blowers are maintenance-free);

Inspect the piping and aeration plate: If the aeration plate is emitting uneven air bubbles, it may be clogged and needs to be removed, cleaned, or replaced.

Safety Warnings

The fan motor must be grounded (to prevent electrical leakage).

Do not disassemble the piping while the fan is running (high-pressure airflow may injure people).

Before long-term shutdown, run the fan at no load for 5 minutes to remove moisture from the fan (to prevent rust).

Common Problems and Solutions

| Frequently Asked Questions | Possible Causes | Solutions |

| Sudden drop in air volume | 1. Air filter clogged; 2. Aeration plate/pipe clogged; 3. Pipeline leak | 1. Clean the filter; 2. Backflush the aeration device; 3. Check the seal |

| The blower noise becomes louder | 1. Motor bearing wear; 2. Pipeline vibration; 3. Lack of engine oil | 1. Replace the bearing; 2. Install the shock absorber; 3. Add engine oil |

| Motor overheating (tripping) | 1. Overload; 2. Cooling fan damage; 3. Unstable voltage | 1. Reduce the load (e.g. reduce the number of aeration discs); 2. Repair the fan; 3. Install a voltage stabilizer |

| Dissolved oxygen meets standards but farmed animals still experience stress | 1. Uneven aeration (localized lack of oxygen); 2. Excessive bubbles (irritating the fish gills) | 1. Rearrange the aeration discs (2-3 meters apart); 2. Replace the nano aeration discs |

Summary

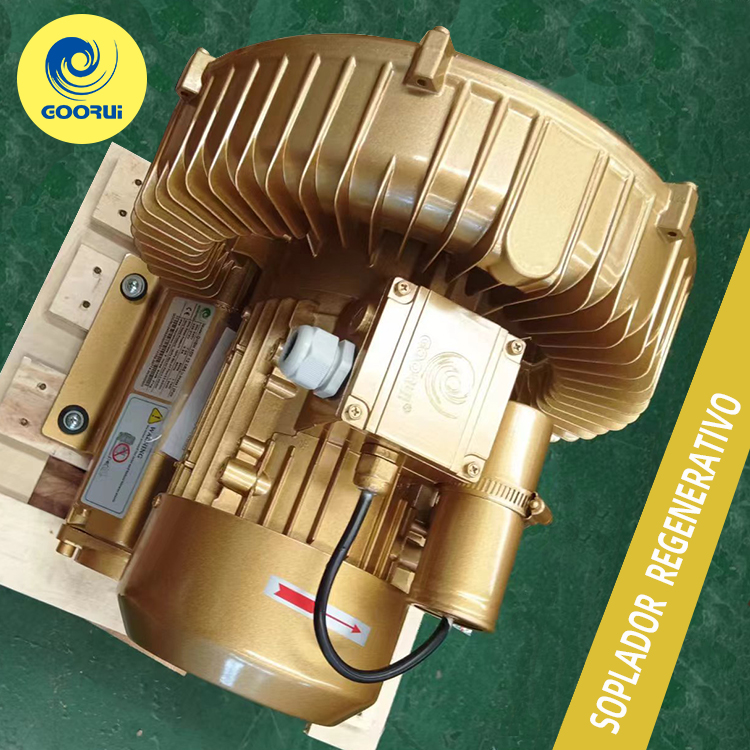

High-pressure blowers are the lifeline of modern high-density aquaculture. Their core value lies in their stable, uniform, and efficient oxygenation capabilities. When selecting a blower, careful consideration should be given to factors such as the aquaculture species, the size of the water body, and the depth. During operation, attention should be paid to routine maintenance and dissolved oxygen monitoring to maximize their effectiveness, reduce aquaculture risks, and improve profitability. If your business depends on quality performance from air technology equipment, then come and talk to GOORUI to find out more about our air technology services and solutions.

Topic

#Aquaculture #FishPond #FishFarm #ShrimpFarming #Aeration #AirSupply #Oxygenation #Agitation #RAS #MBR #WaterPurification