Side channel blowers are widely used in glass machinery. Their core purpose is to leverage their high-pressure, high-speed airflow to facilitate critical processes such as material conveying, positioning, cleaning, drying, and cooling during glass production, processing, and handling. Their application covers the entire glass industry chain, from raw glass production to further processing, and different types of high-pressure blowers (such as vortex and centrifugal blowers) can be adapted to meet specific process requirements.

I. Core Application Scenarios and Operating Principles

The application of high-pressure side channel blowers in glass machinery essentially replaces traditional mechanical contact operations with the “thrust,” “suction,” or “impact” of airflow, preventing scratches and breakage on the glass surface while improving efficiency. Specific application scenarios are as follows:

1. Sheet Glass Production: Cooling and Conveying

In sheet glass production lines for float glass and photovoltaic glass, high-pressure side channel blowers are primarily used for cooling and conveying glass after forming to ensure consistent glass quality.

Lehr Cooling: After forming glass in the tin bath and entering the annealing lehr, the temperature must be gradually reduced to eliminate internal stresses. High-pressure side channel blowers deliver ambient or low-temperature air into the annealing lehr through pipes, creating a uniform “air curtain” that controls the cooling rate of the glass (to prevent excessive cooling and shattering). In some applications, a heat exchanger is used to pre-cool the air before delivery, improving cooling efficiency.

Sheet conveying and positioning: After cutting, the glass sheets are transported contactlessly via a “high-pressure air support conveyor table.” The high-pressure air generated by the blowers is ejected through tiny pores on the conveyor table’s surface, forming a thin “air cushion” between the glass and the tabletop. This suspends the glass and allows it to move smoothly with the airflow, preventing scratches caused by friction with the tabletop. This is particularly suitable for delicate sheets such as ultra-thin and coated glass.

2. Glass Deep Processing: Core Process Support

Glass deep processing (such as tempering, insulating glass, laminating, coating, and edging) is the most concentrated application area for high-pressure side channel blowers, directly affecting processing precision and finished product quality.

| Application process | Specific role | How it works |

| Glass cutting | Fixing glass and removing cutting debris | A high-pressure air suction port is set under the cutting table to firmly adsorb the glass on the table through negative pressure (to avoid displacement during cutting); at the same time, the side fan sprays high-pressure air to blow away the glass debris produced by cutting in time to prevent the debris from scratching the glass surface. |

| Glass edging/polishing | Cooling the grinding head and removing grinding dust | When the edge grinder is operating, the high-speed friction between the grinding head and the glass generates high temperatures and dust. A high-pressure blower sprays air through a nozzle at the contact point between the grinding head and the glass, cooling the grinding head (extending its service life) and blowing away the dust (preventing dust from attaching and affecting the polishing effect). |

| Tempered glass production | Wind grid cooling (core process) | After the glass is heated to its softening point, it enters the tempering air grid. High-pressure fans spray even, high-speed cold air through thousands of small holes within the grid onto the upper and lower surfaces of the glass. This rapidly cools and hardens the glass surface, creating tensile stress within the glass, resulting in a high-strength tempering effect (the fan pressure and wind speed directly determine the strength grade of the tempered glass). |

| Insulating glass production | Glass cleaning, spacer positioning, gas filling assistance | – Cleaning: The dry airflow from the high-pressure side channel blower removes dust and water stains from the glass surface (preventing impurities from forming in the hollow layer and affecting light transmittance). – Positioning: Negative pressure is used to precisely secure the spacers to the glass surface. – Inflation: When filling the hollow layer with an inert gas such as argon, the fan assists in controlling the airflow speed to ensure even gas distribution. |

| Glass coating | Cleaning before coating, airflow control during coating, cooling after coating | – Cleaning: A combination of high-pressure air and vacuum suction is used to thoroughly remove tiny particles from the glass surface (coating requires extremely clean glass; impurities can cause the coating to flake off). – Temperature Control: Airflow regulates the temperature within the coating chamber to ensure a uniform coating layer. – Cooling: After coating, low-pressure, high-speed airflow is used for rapid cooling to improve coating adhesion. |

| Glass Printing | Positioning before printing, drying after printing | – Positioning: Negative pressure secures the glass to the printing table, ensuring precise alignment of the printed pattern. – Drying: Hot air from a high-pressure blower (incorporating a heating device) accelerates the curing and drying of the printed ink, shortening production cycles. |

3. Finished Glass Product Processing: Packaging and Inspection

Finished Product Conveying and Sorting: A combination of “air supports and air curtains” ensures contactless conveyance of finished glass along the sorting line, preventing secondary damage before packaging. During sorting, airflow propels glass of different specifications into corresponding channels.

Pre-Packaging Cleaning: High-pressure cold air (to avoid damaging the glass surface) is used to remove dust from the surface of the finished glass, ensuring a clean finish after packaging.

Inspection Assistance: During surface defect inspection (such as scratch and bubble detection), the steady airflow from the high-pressure blower disperses interfering objects (such as fibers and dust) from the glass surface, ensuring accurate defect detection by inspection equipment (such as CCD cameras).

II. Key Selection Parameters

The requirements for high-pressure side channel blowers in glass machinery vary depending on the process. When selecting a blower, pay special attention to the following parameters to avoid overkill or insufficient pressure:

1. Air pressure (static pressure): This determines the “force” of the airflow.

· Tempered wind screens and negative pressure positioning applications require high air pressure (typically 5-15kPa) to ensure the glass is securely fixed or cool quickly.

· Lower air pressure (1-3kPa) is sufficient for cleaning and drying applications.

2. Air volume: This determines the airflow’s coverage and sustainability.

· Large-sized glass (such as building curtain wall glass) requires high air volumes (typically 10-50 m³/min) for conveying and cooling, ensuring airflow covers the entire glass surface.

· Small-sized glass (such as mobile phone screens) can require lower air volumes.

3. Airflow stability: Airflow fluctuations can directly impact process accuracy (e.g., uneven cooling of tempered glass leading to poor flatness and offset printing positioning). Therefore, it’s important to select a fan with minimal pressure/volume fluctuation (typically ≤±5%). Some high-end equipment is equipped with an airflow pressure stabilizing valve.

4. Noise and vibration: Glass machinery mostly operates in continuous production. Excessive fan noise (e.g., exceeding 85dB) can affect the workshop environment. Low-noise fans (such as vortex fans with silencers, which can reduce noise to below 65dB) should be preferred. Low vibration can also prevent interference with glass positioning accuracy during fan operation.

5. Corrosion resistance and dust resistance: In dusty environments such as glass edging and cutting, the fan must have a good dust-proof structure (such as an air filter). If it comes into contact with moisture after glass cleaning, it must also be made of rust-resistant materials (such as a stainless steel casing).

III. Application Advantages

Compared to traditional mechanical and hydraulic drive systems, the application of high-pressure side channel blowers in glass machinery offers significant advantages:

· Contactless Operation: Airflow secures, transports, and cools the glass, eliminating direct contact between mechanical components and the glass surface. This fundamentally reduces defects like scratches and indentations, making it particularly suitable for high-precision, delicate glass (such as ultra-thin glass and coated glass).

· High Efficiency: The airflow response speed is fast (in milliseconds), enabling rapid positioning and cooling of the glass (for example, the cooling time of tempered glass can be reduced by over 30%), improving production line cycle times.

· Adaptability: By adjusting air pressure and air volume, it can accommodate glass processing requirements of varying thicknesses (0.15mm-20mm) and specifications (from mobile phone screens to ultra-large curtain wall glass), eliminating the need for frequent replacement of mechanical components.

· Low Maintenance Cost: High-pressure side channel blowers (especially vortex blowers) have a simple structure and few wearing parts (primarily bearings). Routine maintenance requires only filter cleaning and lubricant replacement, reducing maintenance costs by approximately 40% compared to complex mechanical transmission systems.

IV. Precautions

· Airflow Uniformity Control: In tempering furnace air grilles, wind support conveying, and other applications, ensure uniform airflow at the blower outlet (this can be achieved by installing an air distributor and regularly cleaning dust from the outlet). Failure to do so can easily lead to uneven cooling and misaligned conveying of the glass.

· Dust Protection: Dust generated by glass edging and cutting can easily enter the blower, causing impeller wear and a drop in air pressure. Therefore, a high-precision air filter (filtration accuracy ≥ 5μm) should be installed at the blower inlet and cleaned or replaced regularly.

· Pressure Matching: Different glass processing machines have different air pressure requirements (e.g., tempering furnace air grilles require high pressure, while cleaning processes require low pressure). A blower must be selected based on the equipment’s parameters to avoid excessive air pressure that could cause glass deformation, or insufficient air pressure that could affect process results.

· Heat Dissipation: High-pressure side channel blowers generate heat when running for extended periods (e.g., a glass production line operating continuously for 24 hours). Ensure the fan’s installation environment is well-ventilated to prevent overheating and burnout of the motor. Install a cooling fan or cooling jacket if necessary.

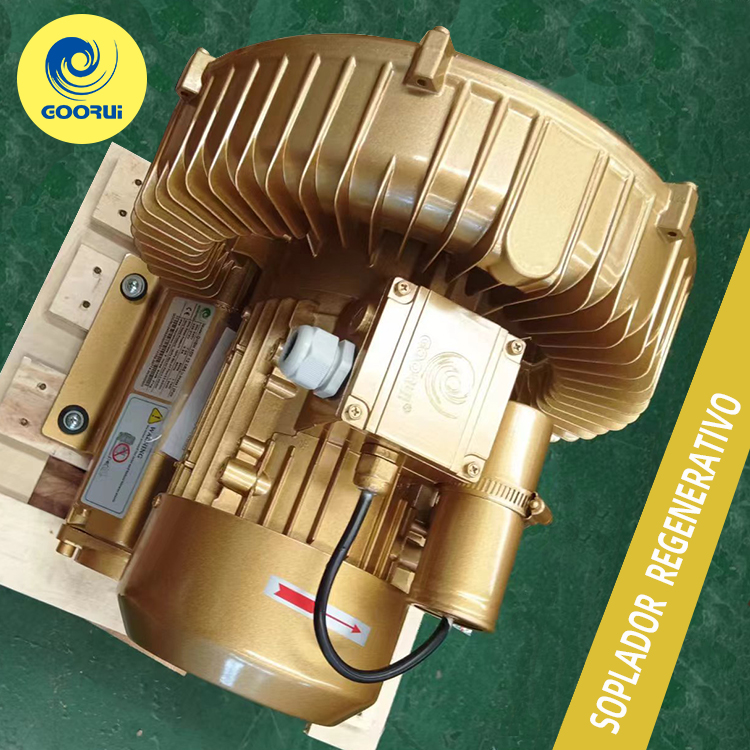

In short, high-pressure side channel blowers have become the core auxiliary equipment for glass machinery to achieve high-efficiency, high-precision and low-damage processing due to their flexible airflow control capabilities. Their application effect is directly related to the quality and production efficiency of glass products. If your business depends on quality performance from air technology equipment, then come and talk to GOORUI to find out more about our air technology services and solutions.