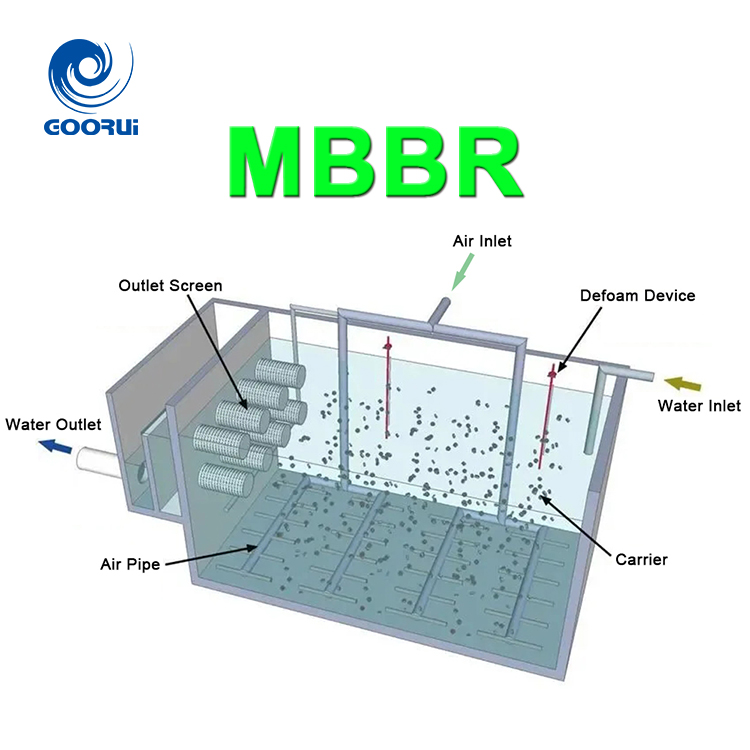

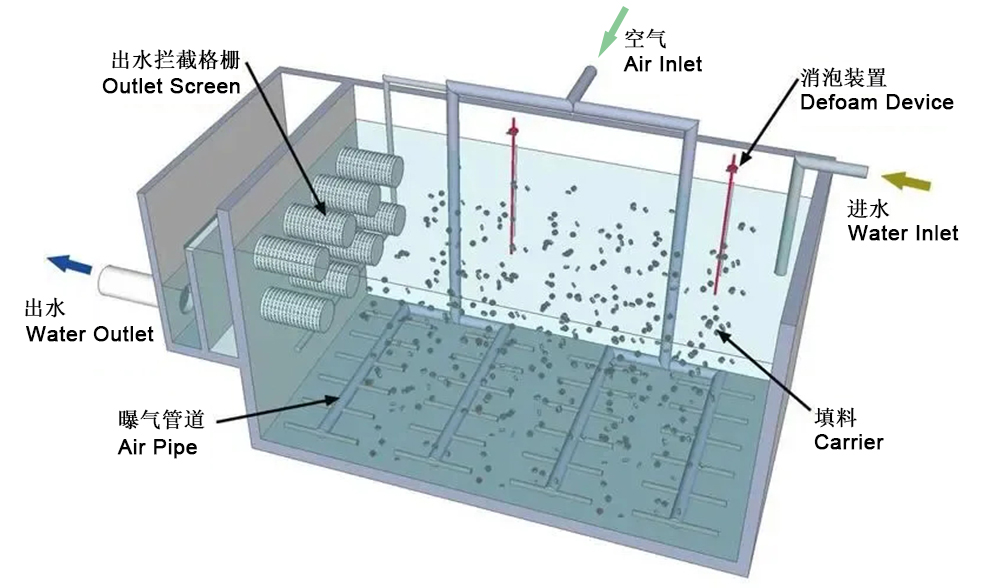

An MBBR in STP refers to a sewage treatment plant that uses the Moving Bed Biofilm Reactor process for treating sewage and industrial wastewater. It utilizes plastic bio-media that floats freely in the aeration tank. These media provide a high surface area for microorganisms to grow and degrade pollutants in the water.

MBBR vs MBR vs SBR – Which is Better?

| Efficiency Comparison (BOD, TSS Removal) | ||

| MBBR excels in volumetric efficiency for BOD and nitrogen removal and is highly robust, but still requires a conventional clarifier for TSS separation, similar to ASP. | MBR stands out for its exceptional effluent quality, particularly for TSS and pathogen removal, due to the physical membrane barrier. It’s often the choice when direct reuse or discharge to sensitive waters is required. | SBR offer highly flexible and efficient systems for achieving stringent BOD, TSS, and especially nutrient removal (nitrogen and phosphorus) through their programmable batch operations. SBBR adds robustness and higher capacity due to the biofilm. |

| Cost Analysis (CAPEX, OPEX) | ||

| MBBR has a moderate to high CAPEX due to the cost of carriers, but its OPEX is generally moderate, benefiting from no RAS pumping. | MBR typically has the highest CAPEX and OPEX due to the cost of membranes, their replacement, the energy for aeration (both biological and membrane scouring), and chemical cleaning. However, the higher effluent quality and smaller footprint can justify this cost in specific scenarios. | SBR has a moderate to high CAPEX due to the need for sophisticated controls and potentially larger tank volumes than a continuous system, but its OPEX can be moderate, especially if nutrient removal is optimized. |

| Footprint Comparison | ||

| MBBR also offers a significantly reduced footprint compared to ASP, but still requires post-clarification. | MBR is the undisputed winner in terms of smallest footprint, making it ideal for urban areas or retrofits where space is limited. | SBR are generally more compact than ASP, as they integrate multiple processes into a single tank. SBBR potentially offers a smaller footprint than a pure SBR due to the higher volumetric efficiency from the biofilm. |

| Operational Complexity | ||

| MBBR is generally moderately complex, requiring attention to carrier retention and post-clarification, but less prone to biomass upsets than ASP. | MBR is generally the most operationally complex due to the need for diligent membrane management, cleaning, and integrity monitoring. | SBR require high levels of automation and skilled operators to manage the precise timing of their batch cycles and optimize for nutrient removal. |

Conclusion

Whether you are planning a new plant or upgrading an existing facility, MBBR provides a future-ready approach that aligns with environmental compliance, performance efficiency, and long-term sustainability.