Technical Benefits of the Side Channel Blowers

Side channel blowers, often referred to as regenerative blowers or vacuum pumps, are frequently utilized in many commercial and industrial applications. The following are some of the essential benefits of side channel blowers that are propelling the demand for these machines:

High Efficiency: Side channel blowers are made to operate with a high level of efficiency. They deliver high flow and pressure ratios while using little power. Therefore, they are affordable options for a range of industrial and business applications.

Minimal Noise: Side channel blowers work with a low level of noise, due to their special design. These provide a pulsing flow of air that makes less noise, compared to other types of blowers.

Low Maintenance & Compact Size: Side channel blowers require little maintenance. They feature a straightforward construction with minimal moving components, which lowers the possibility of malfunctions and maintenance expenses. The small size and compact design of side channel blowers are appropriate for applications with limited space. These blowers are simple to carry and put in confined areas. Therefore, these blowers are highly preferred in the food and waste water treatment industries, which is anticipated to spur the market growth in the coming years.

Oil-free Operation: Side channel blowers don’t need oil for lubrication. Therefore, there is less chance of process air to be contaminated with oil. This qualifies these blowers for using for oil-free products in the food and pharmaceutical sectors.

Versatile: Side channel blowers are versatile and are utilized for both vacuum & pressure applications. These blowers are used for wide-ranging applications, such as pneumatic conveying, wastewater treatment, printing, and packaging. Side channel blowers are a dependable and affordable option for a variety of industrial and commercial applications, owing to their overall advantages.

Limited Features of Side Channel Blowers and Availability of Parallel Products in the Market

More over factors that act as disadvantage to the side channel blowers market are as follows:

Limited Pressure: Side channel blowers have limited pressure capabilities compared to other types of blowers. They are typically used for low-pressure applications and cannot generate the high pressure levels that are required for certain industrial processes.

Limited Flow Rate: Side channel blowers have a limited flow rate, which is not sufficient for high-volume applications. In such cases, larger or more powerful blowers than the side channel blowers are required.

Heat Generation: These blowers generate heat during operation, which affects their efficiency and lifespan. The heat also poses a risk of damage to the process air or surrounding equipment.

Sensitivity to Operating Conditions: Side channel blowers are sensitive to changes in operating conditions, such as variations in temperature or pressure. This affects their performance and efficiency, and requires adjustment to maintain optimal operation.

Noise: In some applications, where noise levels must be kept to a minimum, side channels blowers are being used extensively because they are designed to operate at a low noise during operations. , Hence, the above factors may limit the buyers buying a side channel blower, therefore limiting market growth.

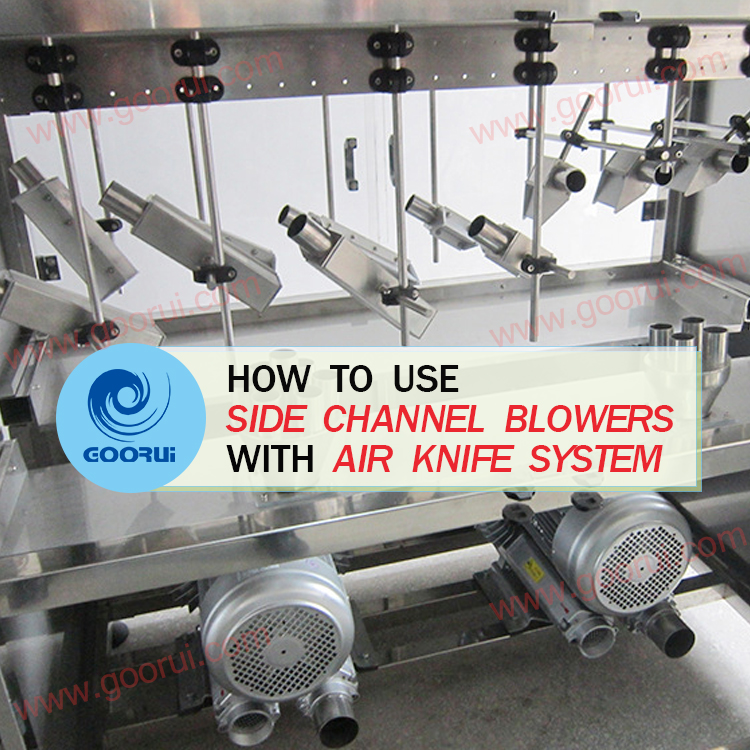

GOORUI always try our best to help our customer, as we said we are not only selling the blowers but also provide a full systems and solution. Contact us on service@goorui.com