Side channel blowers, known for their high efficiency and reliability in generating continuous airflow, play a pivotal role in the ozone industry. Their unique design and operational advantages make them indispensable in various ozone-related applications, ranging from ozone generation to distribution and system cooling. Below is a detailed exploration of their key applications and contributions:

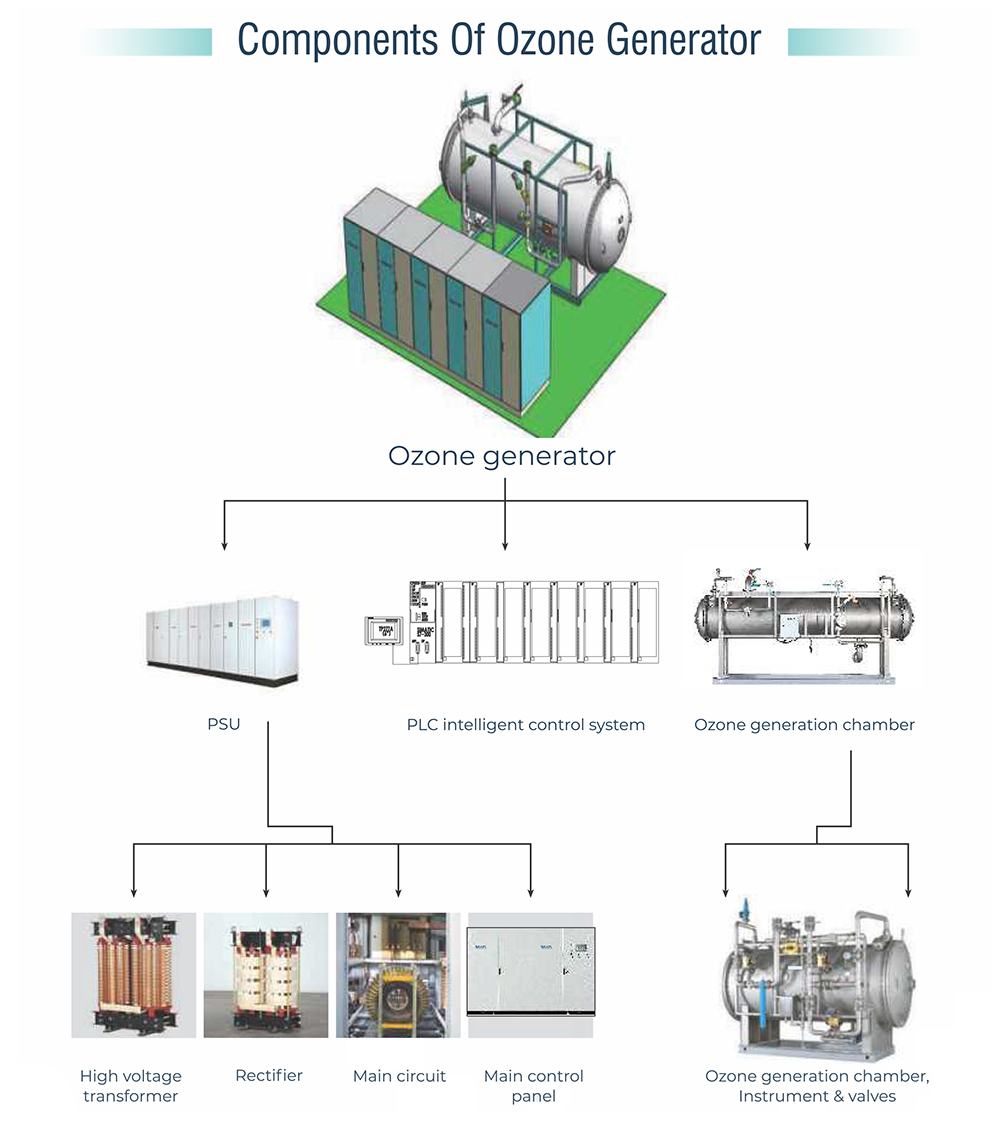

1. Ozone Generation: Oxygen Supply and Air Compression

Ozone generators require a stable supply of oxygen or dry air to produce ozone (O₃) through electrical discharge or UV irradiation. Side channel blowers excel in delivering consistent airflow, ensuring optimal oxygen input for efficient ozone production. Their ability to operate under varying pressures makes them ideal for both small-scale and industrial ozone systems, particularly in water-cooled or air-cooled generators.

2. Cooling Systems in Air-Cooled Ozone Generators

Air-cooled ozone generators, favored for their simplicity and cost-effectiveness, rely on side channel blowers for thermal management. These blowers dissipate heat generated during ozone production, maintaining equipment stability and prolonging service life. Compared to water-cooled systems, air-cooled designs reduce maintenance complexity and operational costs, aligning with the industry’s trend toward energy-efficient solutions.

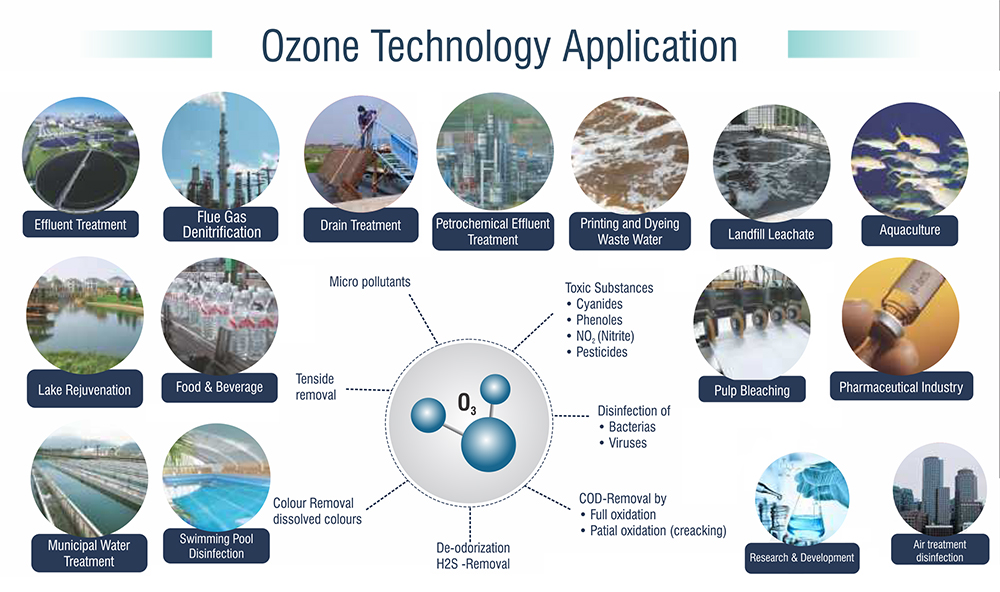

3. Ozone Distribution in HVAC and Water Treatment Systems

In applications such as air purification and water treatment, side channel blowers facilitate the uniform dispersion of ozone. For instance, in HVAC systems, blowers integrate with ozone generators to inject ozone into air ducts, ensuring thorough disinfection of large spaces like hospitals, laboratories, and food processing facilities. Similarly, in water treatment plants, blowers assist in dissolving ozone into water, effectively eliminating pathogens and organic contaminants.

4. Material Durability for Corrosion Resistance

Ozone’s strong oxidizing properties demand equipment materials resistant to corrosion. Side channel blowers constructed with ozone-resistant components (e.g., stainless steel or specialized coatings) ensure longevity in harsh environments. This durability is critical in industries such as chemical processing and wastewater treatment, where ozone exposure is frequent.

5. Energy Efficiency and Environmental Compliance

Modern side channel blowers are designed to minimize energy consumption while maximizing output, aligning with global sustainability goals. Their low-noise operation and compatibility with renewable energy systems further enhance their appeal in eco-conscious industries. For example, in food preservation and pharmaceutical manufacturing, these blowers support ozone-based sterilization without compromising environmental standards.

Conclusion

Side channel blowers are integral to the ozone industry, driving advancements in disinfection, environmental protection, and industrial efficiency. Their versatility in oxygen supply, cooling, ozone distribution, and corrosion resistance positions them as a cornerstone technology for current and future applications. As the demand for ozone-based solutions grows—spanning water treatment, healthcare, and food safety—the role of side channel blowers will continue to expand, underpinning innovation and sustainability in this dynamic field.