The use of side channel blowers in wastewater treatment plants (STP/WWTP) offers several key benefits, as highlighted across multiple sources.

1. High Efficiency and Pressure

Side channel blowers are designed to deliver high pressure (up to 410 inH₂O) and large volume flow (up to 1,300 cfm), making them ideal for demanding applications like aeration in biological treatment processes. This ensures sufficient oxygen transfer for microbial activity, critical for breaking down organic matter in wastewater. Their efficiency in gas and air boosting also supports biogas production in anaerobic digestion systems.

2. Oil-Free Operation

A standout feature is their oil-free design, which eliminates the risk of contaminating treated water or sludge. This aligns with environmental regulations and ensures compliance with standards such as China’s GB18918-2002 for pollutant discharge. Oil-free operation also reduces maintenance costs and avoids fouling in sensitive systems like membrane bioreactors.

3. Durability and Corrosion Resistance

Constructed with aluminum casings (anodized for added protection) and stainless steel shafts, these blowers withstand harsh environments, including exposure to corrosive gases like hydrogen sulfide and moisture in WWTPs. This extends their operational lifespan and reduces replacement frequency.

4. Low Maintenance and 24/7 Reliability

Side channel blowers are maintenance-free and built for continuous operation, even under heavy workloads. For instance, the LT1 720 H16 model is explicitly noted for its ability to run 24 hours a day without downtime, ensuring uninterrupted treatment processes. Their simple design with minimal moving parts further reduces wear and tear.

5. Versatility in Applications

These blowers are adaptable to multiple WWTP processes:

Aeration: Critical for activated sludge systems and oxidation ditches.

Biogas Boosting: Enhances methane recovery in anaerobic digesters.

Vacuum Systems: Used in sludge dewatering and pneumatic conveyance.

Odor Control: Supports air circulation in enclosed treatment facilities to mitigate harmful gases.

6. Energy Efficiency and Low Noise

Advanced designs, such as TEFC (Totally Enclosed Fan-Cooled) motors and optimized impellers, contribute to energy savings. Additionally, their low noise levels (below 75dB in some models) improve workplace safety and reduce noise pollution.

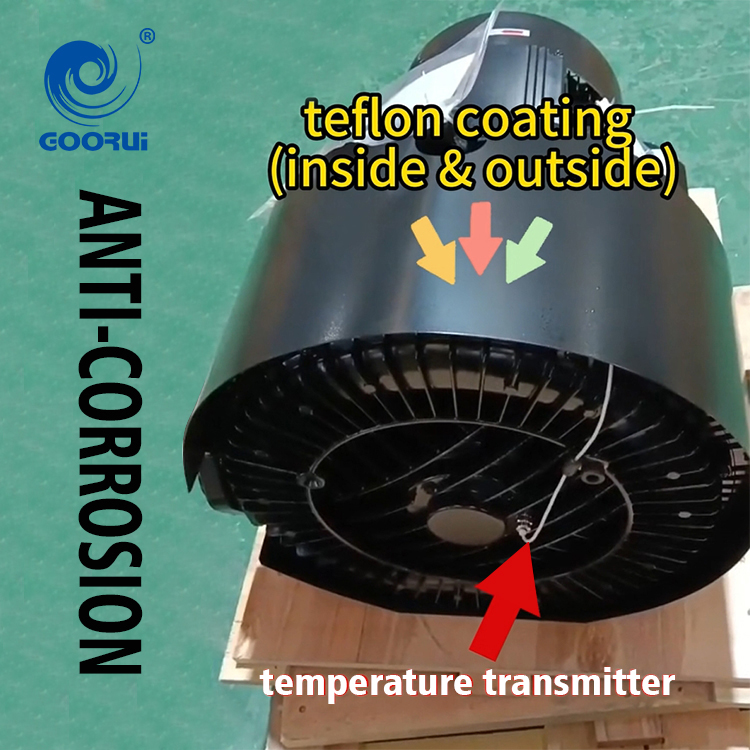

GOORUI customzied blower with advantages below :

GOORUI Blower with TEFLON coating (inside & outside ) / PTFE;

PTC in the motor coil;

PT 100 in the bearing side;

temperature transmitter;

High temperature resistance 200 Deg C.

If your business depends on quality performance from air technology equipment, then come and talk to GOORUI to find out more about our air technology services and solutions.