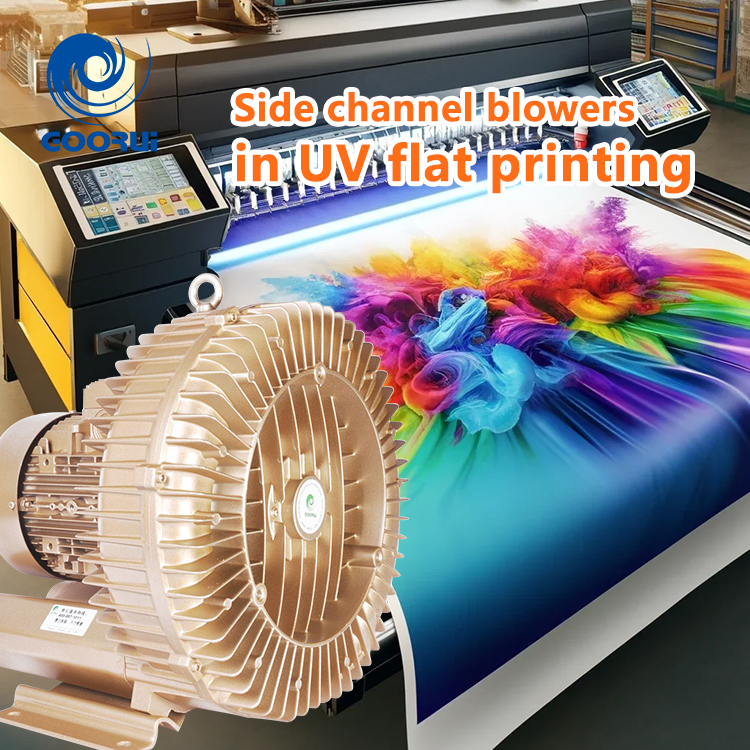

When side channel blowers (also called ring blowers or regeneration blowers) are applied in UV flat printing, the following key points and steps are usually involved:

1. Features of side channel blowers

·High pressure and low flow: suitable for scenarios where stable airflow is required but space is limited.

·Compact design: small size and easy to integrate into printing equipment.

·Low maintenance: no internal valves, suitable for long-term operation.

2. Uses in UV printing

Side channel blowers may be used for:

·Drying/curing: accelerate UV ink curing, which requires a UV lamp system.

·Cooling: prevent overheating of the nozzle or electronic components.

·Material fixation: ensure flatness by negative pressure adsorption of the medium (such as coils).

3. Key points of system integration

Airflow control:

Need to match the printing speed to avoid overdrying or undercuring.

The fan speed can be adjusted by the inverter to achieve dynamic control.

Air path design:

Use uniform nozzles or diffusers to ensure uniform airflow distribution.

Avoid turbulence affecting the printing accuracy.

Compatibility:

The fan material must be resistant to UV ink volatiles (such as aluminum alloy or stainless steel).

Noise and vibration must be controlled within the allowable range of the equipment.

4. Selection parameters

·Air pressure/flow: Calculate the requirements based on the printing width and media type.

·Power supply: Commonly single-phase or three-phase, matching the equipment power supply.

·Ambient temperature: Ensure that the fan operates stably at high temperatures near the UV lamp.

5. Maintenance and optimization

·Regular cleaning: Prevent ink dust from clogging the air duct.

·Monitoring performance: Check whether the wind pressure drops and replace the filter in time.

·Energy-saving design: Automatically reduce the wind speed during non-continuous printing.

6. Example configuration

Equipment: UV flatbed inkjet printer (format 1.5m×3m).

Blower selection: high-pressure side channel blower (such as 0.75kW, maximum pressure 300mbar).

Installation location: both sides or bottom of the nozzle, with negative pressure adsorption table.

Through reasonable selection and integration, side channel fans can effectively improve the quality and efficiency of UV printing, especially in high-speed or large-format applications.