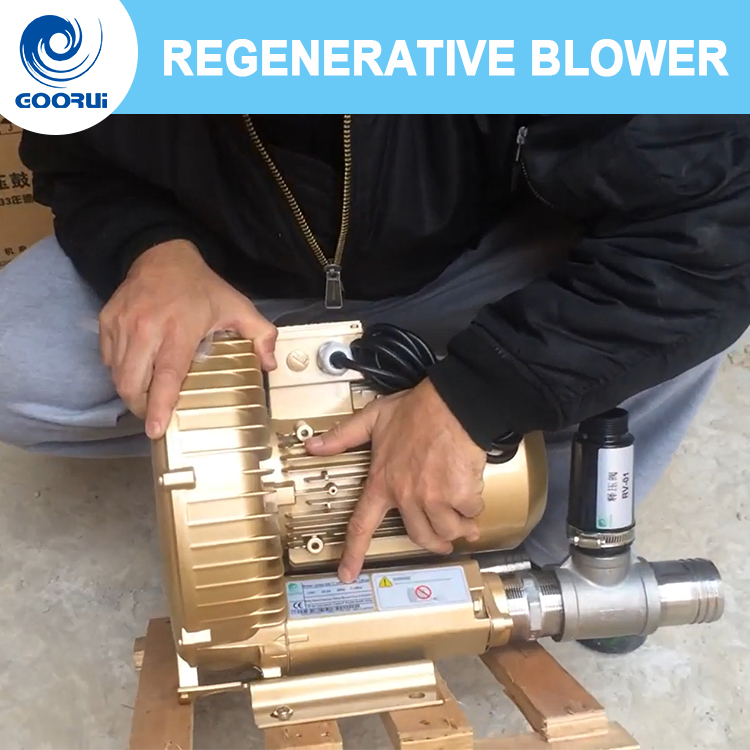

A regenerative blower, also known as a side-channel blower, is a type of blower that uses a rotating impeller to move air or gas. It’s designed for moving large volumes of air at low pressures or vacuums. Key aspects of operation include proper ventilation, temperature considerations, and maintaining airflow.

Key Aspects of Operation:

Proper Ventilation:

Ensure adequate airflow around the blower to prevent overheating and maintain optimal operating temperatures. The ambient temperature should be within the specified range.

Temperature Management:

Regenerative blowers can generate significant heat during operation. Avoid touching the blower during operation and allow it to cool down before handling. If operating near the blower’s maximum pressure or vacuum duty, install a pressure gauge to monitor performance.

Airflow and Filtration:

Operate the blower with clean, dry air. If the blower is located where dust or moisture is present, install a filter on the suction side of the piping to prevent contaminants from entering.

Safety Precautions:

Disconnect power before installation or maintenance. Install safety guards to prevent accidental contact with rotating parts. Wear appropriate eye and hearing protection due to the potential for eye damage from the air stream or noise levels.

Installation:

Install the blower in a location that is protected from the elements and where it can be properly grounded. Use properly sized fittings and consider using a relief valve for pressure applications and a vacuum relief valve for vacuum applications.

Maintenance:

Regularly inspect and lubricate the blower, Clean or replace air filters to maintain optimal airflow.

Troubleshooting:

If the blower is not operating correctly, consult the troubleshooting section of the manual for potential causes and solutions. Common issues include motor overheating, reduced airflow, or unusual noise.

Additional Considerations:

Explosion-proof motors:

If handling flammable or explosive gases, use a blower with an explosion-proof motor.

Corrosive or aggressive gases:

Special blower configurations may be required for handling corrosive or aggressive gases.