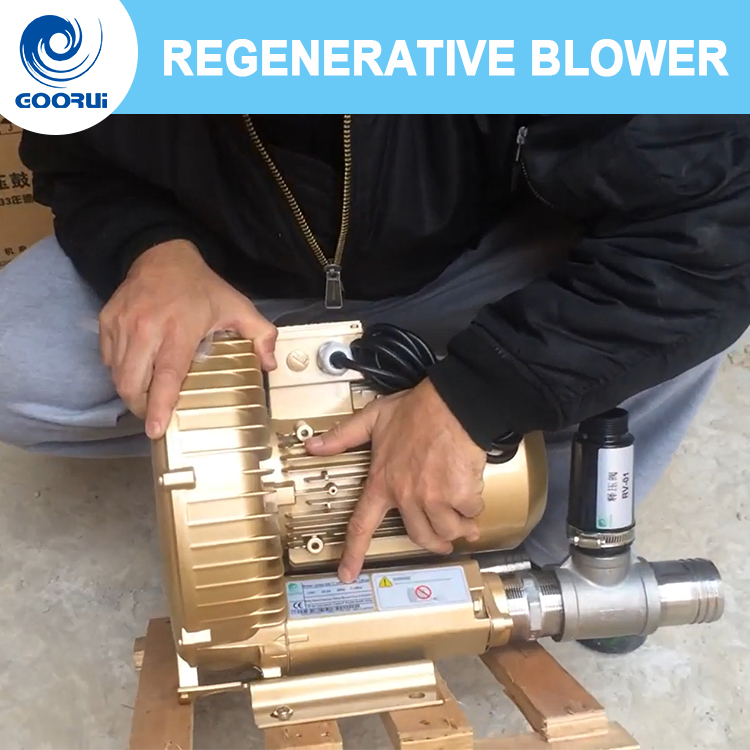

As a well-known high-pressure blower manufacturer at home and abroad, Goorui has always put safety production first. Not only do we pay special attention to the safe use of our high-pressure blowers during production, we also pay special attention to the safe use of our high-pressure blowers. Therefore, we have compiled a high-pressure blower safety manual for your reference. Because each company’s products are different, this manual is for reference only. For specific usage, please consult our engineers.

1. Pre-Start Checklist

Check Wiring:

• Ensure the power supply voltage matches the blower’s nameplate (e.g., 3-phase 380V/50Hz).

• Confirm the motor rotation direction is correct (usually indicated by an arrow on the housing).

Inspect Fasteners:

• Make sure all bolts and nuts are securely tightened to prevent vibration-induced loosening.

Check Air Inlet/Outlet:

• Ensure there is no blockage.

• Inlet should not be sealed off.

• Clean filters or silencers if installed.

Check Bearings & Lubrication:

• Most blowers are maintenance-free, but verify there are no unusual noises or resistance in the bearings.

2. Startup Procedure

Start Without Load:

• It is recommended to start the blower without load (disconnected from application equipment) during first-time use or after installation.

Gradually Apply Load:

• Once the blower runs smoothly, connect it to end equipment such as air knives, suction plates, or diffusers.

• If using a frequency converter (VFD), increase frequency gradually to avoid sudden torque.

Monitor Current:

• Watch the current during startup; it should not exceed the motor’s rated current.

3. During Operation

Avoid Overpressure Operation:

• Running beyond rated pressure may cause motor overload and damage.

Monitor Temperature:

• Outlet temperature rise is normal but should not exceed 80–100°C.

• If overheating occurs, check for pipe blockages or high backpressure.

Listen for Unusual Sounds or Vibrations:

• The blower should emit a consistent, high-pitched sound.

• Sharp noise, scraping, or vibration may indicate a mechanical issue.

4. Shutdown and Maintenance

Normal Shutdown:

• Disconnect the load first, then power off the blower.

• If using a VFD, ramp the frequency down to 0Hz before shutting off.

Routine Cleaning:

• Regularly clean inlet filters or silencers.

• In dusty environments, inspect and clean every 1–2 weeks.

Periodic Checks:

• Every 6–12 months, check motor bearings, insulation resistance, and winding temperature.

5. Common Issues & Troubleshooting

| Problem | Possible Cause | Solution |

| Motor Overheating | Overload, poor ventilation, wrong voltage | Check current, clean vents, verify voltage |

| Excessive Noise | Foreign object, bearing failure, impeller contact | Stop and inspect blower |

| Low Airflow | Leakage, clogged filter | Check for air leaks, clean filter |

| Startup Failure | Undervoltage, capacitor fault (single phase), high load | Check power supply and startup conditions |