GOORUI vortex air pumps (also known as ring blowers) play a key role in foam molding (such as EPS, EPP, PU and other foam products) with the characteristics of stable pressure, moderate flow, smooth operation and easy maintenance. Its core function is to optimize production efficiency and product quality through positive pressure air supply or negative pressure air extraction in accordance with the requirements of each link of foam molding. The following are specific application scenarios and working principles:

Foaming stage: Helping bubbles to form evenly

The core of foam molding is to mix raw materials (such as expandable polystyrene beads, polyurethane prepolymers, etc.) with gas to form a uniform bubble structure. The role of the vortex air pump at this stage is to stabilize the supply of air flow to ensure that the bubbles are fine and evenly distributed.

·EPS pre-foaming stage: Expandable polystyrene (EPS) beads need to be introduced into the pre-foaming machine with air to absorb heat and expand. The continuous, pulse-free airflow provided by the vortex air pump can evenly wrap the beads, avoid local over-expansion or under-expansion, ensure the uniform particle size of the beads (usually controlled at 0.5-5mm), and lay the foundation for subsequent molding.

·Polyurethane foaming assistance: In the production of polyurethane foam, air needs to be introduced to form bubbles when the raw materials are mixed. The low-pressure airflow of the vortex air pump can accurately control the amount of gas injection, and cooperate with the stirring device to make the bubbles disperse more evenly, reducing defects such as “large bubbles” and “cavities” caused by unstable airflow.

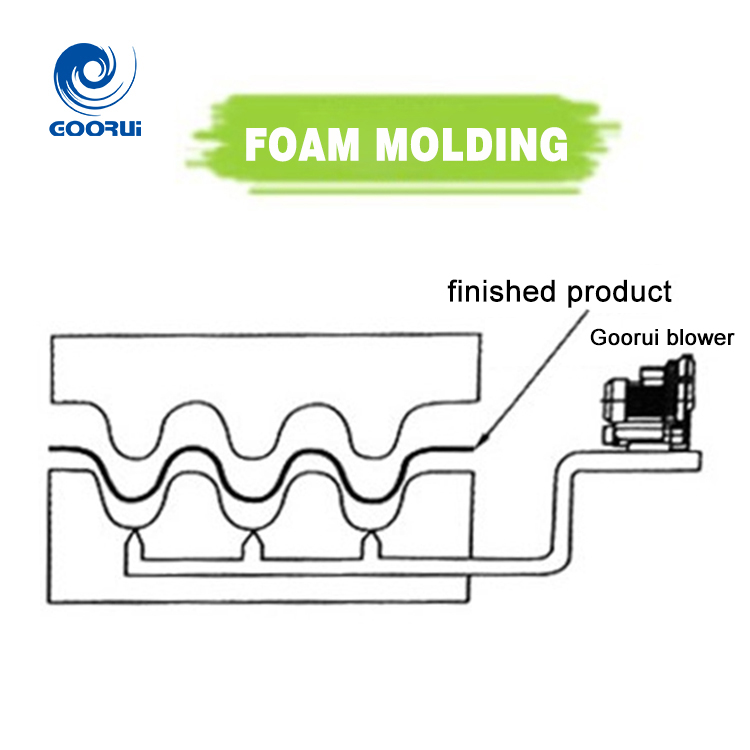

Molding stage: ensure that the mold is tightly filled

Foam molding needs to be finalized in the mold, and the raw materials need to fully fill the mold cavity, while exhausting excess gas to avoid missing corners, depressions or uneven surfaces of the product. The vortex air pump achieves this goal through negative pressure extraction or positive pressure pressurization.

·Mold exhaust (negative pressure exhaust): When the raw materials (such as EPS beads) are injected into the mold, air will remain in the mold. If it is not discharged, it will hinder the filling of the raw materials. The vortex air pump is connected to the exhaust hole of the mold through a pipe, and uses negative pressure to quickly extract air, so that the raw materials fit closely to the inner wall of the mold under pressure, ensuring the dimensional accuracy of the molded product (the error can be controlled within ±0.1mm).

· Auxiliary pressurization (positive pressure air supply): When some high-density foams (such as EPP foam) are molded, a certain pressure needs to be applied to the raw materials in the mold to reduce the bubble gap. The vortex air pump can send a stable airflow into the mold through positive pressure, and cooperate with heating to further expand and compact the raw materials, thereby improving the compressive strength of the product (such as the compressive strength of EPP automotive parts can reach more than 10MPa).

Cooling and curing stage: accelerate shaping efficiency

After the foam is molded, it needs to be cooled quickly to fix the shape to avoid deformation due to continuous high temperature. The vortex air pump accelerates heat dissipation through forced air circulation, shortens the cooling time, and improves the production cycle.

· Heat dissipation on mold surface: After heating and molding, the mold temperature is high (such as EPS mold temperature is about 100-150℃). The strong airflow generated by the vortex air pump can be blown directly to the outer wall of the mold or through the built-in air duct of the mold to accelerate the heat transfer to the air, so that the mold temperature drops below 50℃ within 5-10 minutes to meet the needs of continuous production.

· Cooling of product surface: For large foam products (such as foam packaging pads, insulation boards), the internal heat is not easy to dissipate after molding. The vortex air pump blows room temperature air to the surface of the product through the air duct to form convection heat exchange, so that the center temperature of the product quickly drops to room temperature, avoiding shrinkage and deformation caused by slow cooling.

Demolding stage: auxiliary product separation

Some foam products (especially molds with complex shapes) may be difficult to demold due to the adsorption force of the inner wall of the mold or the pressure difference. The vortex air pump assists separation through positive pressure blowing or negative pressure adsorption to reduce manual intervention.

· Positive pressure demoulding: At the moment of mold opening, the vortex air pump blows high-pressure air into the gap between the mold cavity and the product to form an “air cushion” to push the product out of the inner wall of the mold to avoid damage to the corners caused by manual prying (such as special-shaped foam for home appliance packaging).

· Negative pressure removal: For lightweight foam products (such as disposable foam lunch boxes), the negative pressure adsorption device of the vortex air pump (with a suction cup) can be used to “suck away” the molded product from the mold and quickly transfer it to the next process to improve the degree of automation.

Advantages: Why choose a vortex air pump?

Compared with piston pumps, Roots blowers and other equipment, vortex air pumps are more adaptable in foam molding, and their core advantages include:

·Stable airflow: Pulse-free airflow ensures uniform bubbles and consistent mold filling, reducing product defect rates;

·Lower energy consumption: At the same flow rate, the power of vortex air pumps is 20%-30% lower than that of Roots blowers, which is suitable for continuous production scenarios;

·Easy maintenance: The structure is simple (no pistons, blades and other vulnerable parts), and only the filter needs to be cleaned daily, and the service life can reach more than 8,000 hours;

·Controllable noise: After installing a muffler, the noise can be reduced to below 60 decibels, which meets the environmental protection standards of the workshop.

Summary

GOORUI vortex air pump has become a key auxiliary equipment for the foam molding production line through the full process of “stable flow air supply – precise pressure control – efficient heat dissipation – auxiliary demoulding“. Its application directly affects the density uniformity, dimensional accuracy and production efficiency of foam products, especially in automated and large-scale production (such as automotive foam accessories and building insulation boards), and is one of the core tools to improve product quality and production capacity.