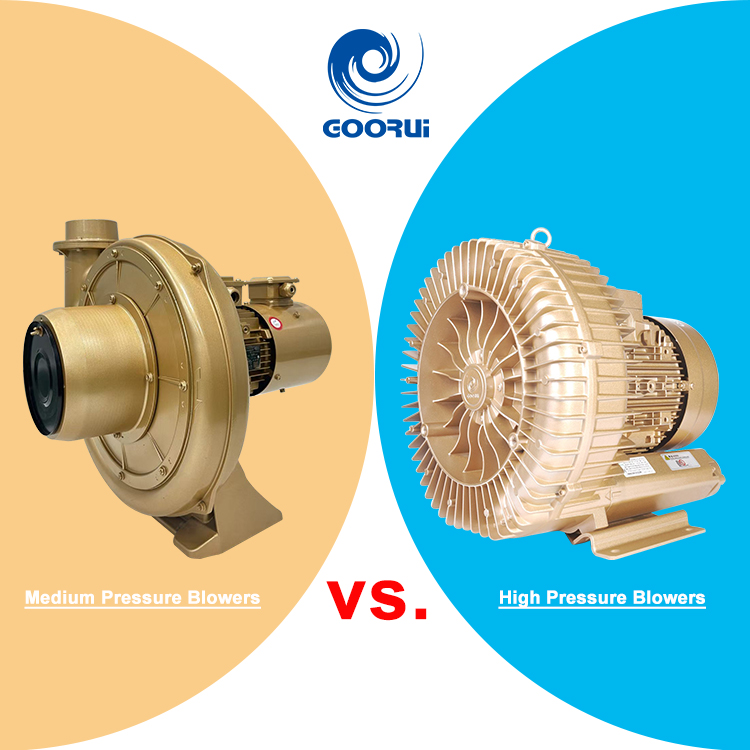

Medium and high-pressure blowers are centrifugal fans used to move air or gas, but they differ in their pressure and airflow characteristics, as well as their applications. Medium-pressure blowers are typically used where a balance of pressure and flow rate is needed, such as in ventilation, air conditioning, and certain industrial processes. High-pressure blowers, on the other hand, are designed for applications requiring high pressure and lower airflow, such as pneumatic conveying, combustion air supply, and industrial drying.

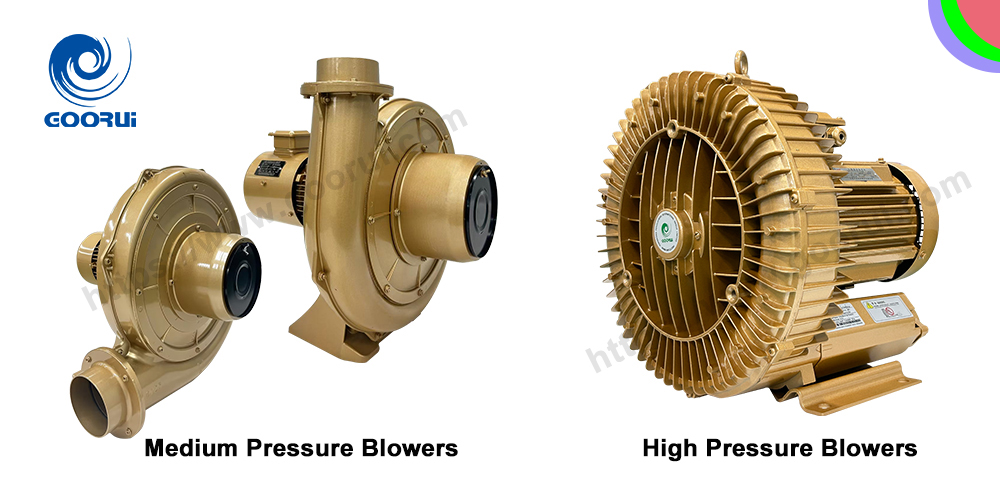

Medium Pressure Blowers:

Pressure Range:

Medium-pressure blowers operate within a range of moderate pressures, typically from 1,300 Pa to 9,600 Pa.

Airflow:

They offer a balanced airflow and pressure for various applications.

Applications:

Commonly found in ventilation systems, air conditioning, and industrial processes where moderate air pressure and flow are required, such as in cooling towers, automobiles, and ships.

Example:

The Elektror RD series is a medium-pressure fan that offers a wide range of sizes and airflow/pressure combinations.

High Pressure Blowers:

Pressure Range:

High-pressure blowers are designed for higher pressure levels, often exceeding those of medium-pressure blowers.

Airflow:

They prioritize high pressure over high airflow, making them suitable for applications needing powerful air movement against significant resistance.

Applications:

High-pressure blowers are used in pneumatic conveying, combustion air supply, industrial processes like drying and cooling, and other applications where high pressure is essential.

Example:

AirPro Fan & Blower Co. offers high-pressure centrifugal blowers for industrial applications requiring high static pressure and low airflow.

Key Differences:

Pressure and Flow Ratio:

High-pressure blowers prioritize high pressure, while medium-pressure blowers balance pressure and airflow.

Application Focus:

Medium-pressure blowers are often used for ventilation and general air movement, while high-pressure blowers are more specialized for applications like material conveying and combustion air.

Design:

High-pressure blowers may feature specialized impeller designs for optimal performance at high pressures.

In essence, the choice between a medium and high-pressure blower depends on the specific requirements of the application, with medium-pressure blowers offering a balance of pressure and flow and high-pressure blowers providing high-pressure capabilities for more demanding tasks.