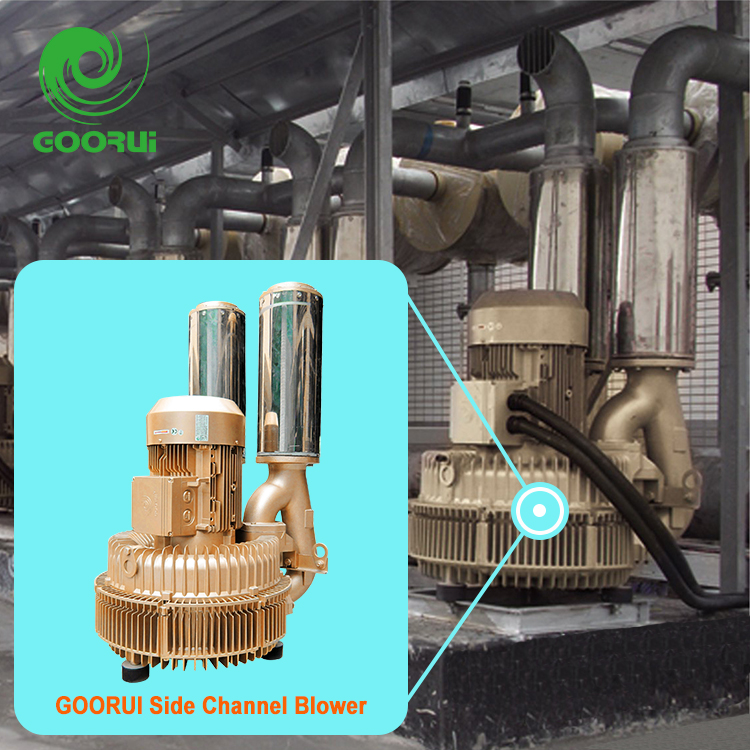

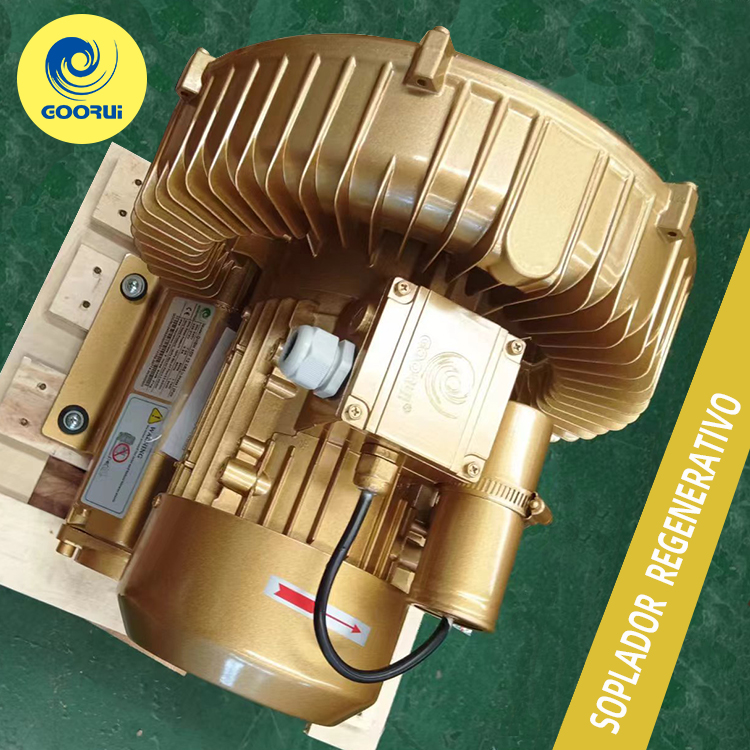

GOORUI Side channel blowers (also known as regeneratIve blowers or ring blowers) have unique advantages in the field of flue gas extraction, especially suitable for scenarios with medium pressure, medium flow rate, and high requirements for gas cleanliness and stability.

The side channel blower forms a high-speed airflow in the annular channel through the rotation of the impeller. It achieves gas compression by utilizing centrifugal force and the side channel structure, capable of generating a static pressure of up to 750 mbar (75kPa). This design enables it to perform exceptionally well in overcoming pipeline resistance and maintaining a stable extraction flow rate, making it suitable for scenarios requiring moderate pressure in flue gas extraction systems (such as incinerators, furnaces, etc.). Compared with centrifugal fans, side-channel blowers have higher efficiency under high static pressure and a wider range of flow regulation.

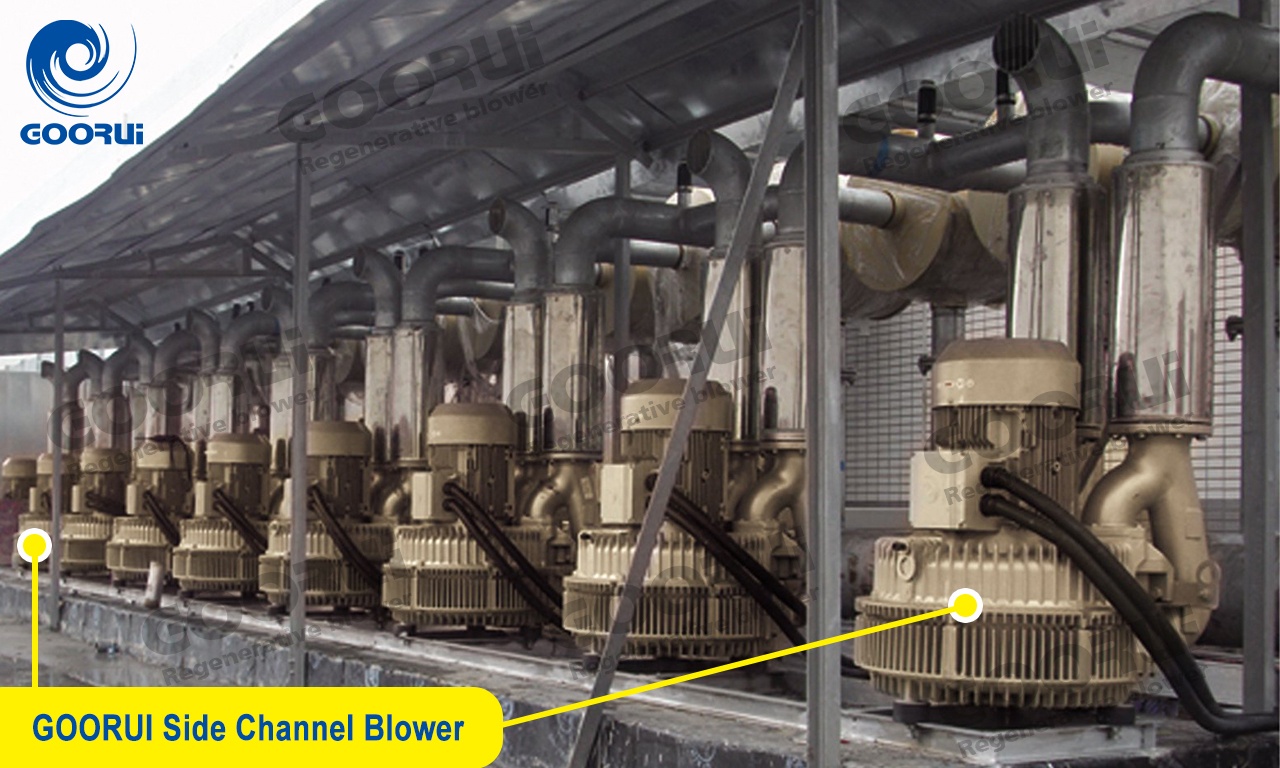

Typical application scenarios and cases

Industrial flue gas treatment

Incinerators and furnaces: Side channel blowers are used to extract high-temperature flue gas generated by combustion (such as below 300°C), and in combination with a waste heat recovery system, energy consumption can be reduced. For instance, Sinopec Qingdao Refining & Chemical Company has adopted blowers in its continuous reforming heating furnaces to recover the waste heat from flue gas, reducing the flue gas temperature from 249°C to 80°C.

Boiler denitrification and desulfurization: In the SCR/SNCR system, the side channel blower evenly injects the reducing agent (such as ammonia) into the flue gas, and its stable pressure output ensures the reaction efficiency.

Waste gas treatment and emission control

Welding fume treatment: Through the negative pressure suction of the side channel blower, the fumes and harmful gases (such as ozone and nitrogen oxides) generated during the welding process can be efficiently collected, purifying the air in the workshop.

Incinerator tail gas emission: It is used to extract the high-temperature tail gas after incineration, and in combination with activated carbon adsorption or catalytic oxidation devices, achieve deep treatment of pollutants such as dioxins.

Adaptability to special environments

High-humidity flue gas: The oil-free design of the side channel blower prevents condensate water from mixing with grease, thus avoiding pipe blockage. For instance, when treating flue gas containing steam in a waste incineration plant, its stability is superior to that of traditional fans.

Flammable and explosive scenarios: Some models (such as explosion-proof types) can be used to handle flue gas containing flammable gases (such as chemical tail gas), ensuring safety through explosion-proof motors and anti-static coatings.

Key parameters for selection and design points

Core parameter matching

Pressure and flow rate: Calculate the required static pressure based on the system resistance (typically 20-50 kpa), and simultaneously meet the flue gas flow rate requirements (such as 500-5000 m³/h).

Temperature and medium composition

If the flue gas temperature exceeds 150°C, water-cooled type or high-temperature resistant materials (such as nickel-based alloy impellers) should be selected.

When corrosive gases are present, stainless steel casings and PTFE-coated impellers should be given priority.

When the dust content is high, a pre-filtering device should be configured and a wear-resistant impeller (such as one with tungsten carbide coating) should be selected.

System design optimization

Cooling and noise reduction

High-temperature flue gas requires the configuration of an air-air heat exchanger or water-cooled jacket to reduce the intake air temperature to the temperature range that the fan can withstand.

The integrated muffler can keep the noise below 70 dB, meeting the noise standards of the workshop.

Intelligent control: By adopting variable frequency speed regulation technology, the rotational speed is adjusted in real time according to the flue gas flow, reducing energy consumption (energy savings can reach 30%). Meanwhile, predictive maintenance is achieved by monitoring the temperature and vibration of the bearings through Internet of Things sensors.

The advantages over traditional solutions

Compared with centrifugal fans, side-channel blowers have higher efficiency under high static pressure and are smaller in size, making them suitable for renovation projects with limited space. For instance, in the treatment of chemical waste gas, under the same pressure, the energy consumption of side-channel fans is 15% lower than that of centrifugal fans.

Compared with Roots blowers, side-channel blowers have smoother flow regulation and no periodic pulsation, avoiding impact on downstream equipment such as bag filters.

Maintenance and safety precautions

Daily maintenance

Regularly clean the air intake filter to prevent blockage and pressure drop.

Check the bearing temperature (it is recommended to be ≤75°C) and vibration value, and replace the grease in time (every 2000 hours of operation).

Safe operation

The high-temperature flue gas system needs to be equipped with temperature interlock protection. When the intake gas temperature exceeds the threshold, it will automatically shut down.

When handling flammable and explosive gases, it is necessary to ensure that the fan is well grounded and to use explosion-proof motors and electrical components.

Summary

Side channel blowers, with their high static pressure, oil-free operation, temperature resistance and corrosion resistance, have become one of the mainstream choices in the field of flue gas extraction. When selecting the type, it is necessary to comprehensively consider the flue gas temperature, composition, pressure requirements and environmental protection standards, and give priority to choosing products with intelligent control and modular design. With the development of materials science and Internet of Things technology, side channel blowers will be further upgraded towards high efficiency, low noise and intelligence in the future, providing more reliable solutions for industrial flue gas treatment.