A vortex blower, also known as a regenerative blower or side channel blower, is a type of blower that uses a rotating impeller to create a vortex of air, generating both airflow and pressure. These blowers are known for their compact size, quiet operation, and suitability for a wide range of applications requiring continuous, non-pulsating air delivery.

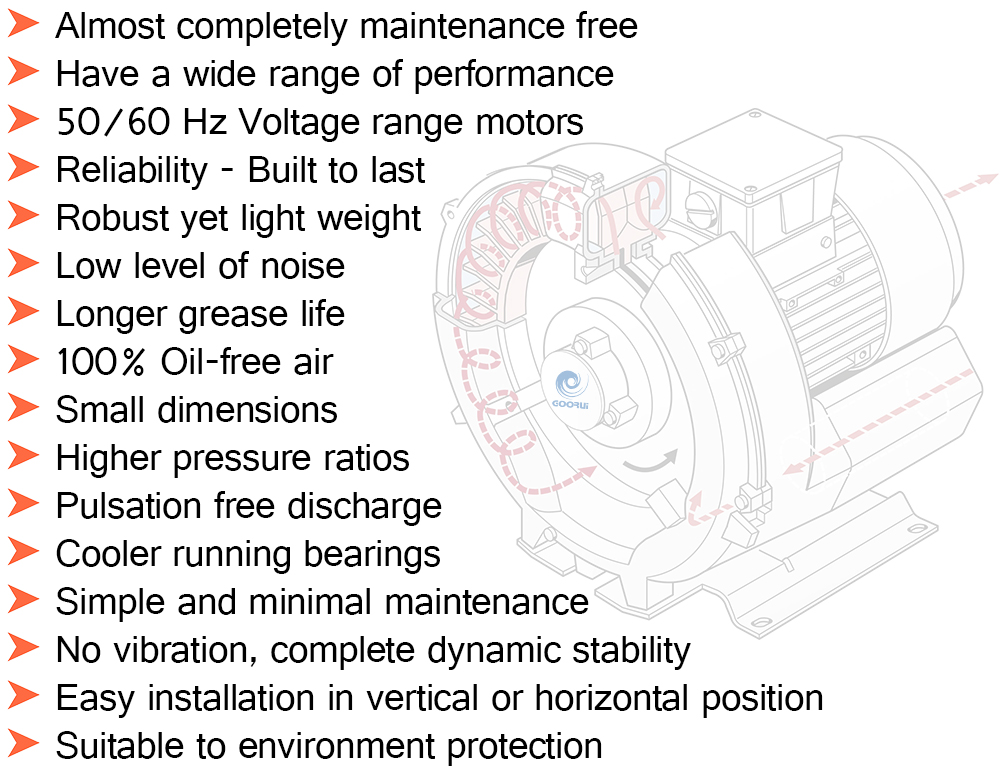

Key Features and Benefits:

Non-Positive Displacement:

Unlike some other types of blowers, vortex blowers operate without positive displacement of air, meaning they don’t trap and force air through a specific chamber.

High Pressure and Airflow:

They can produce significant pressure and airflow, making them suitable for applications like wastewater treatment aeration, pneumatic conveying, and dust collection.

Compact Design:

Vortex blowers are generally smaller and lighter than positive displacement blowers, making them easier to integrate into various systems.

Low Maintenance:

They are known for their low maintenance requirements, which can translate to reduced downtime and lower operating costs.

Quiet Operation:

Vortex blowers typically operate with lower noise levels compared to some other blower types.

Oil-Free Air Delivery:

They are designed to provide oil-free air, which is crucial in applications where air contamination is undesirable.

Applications:

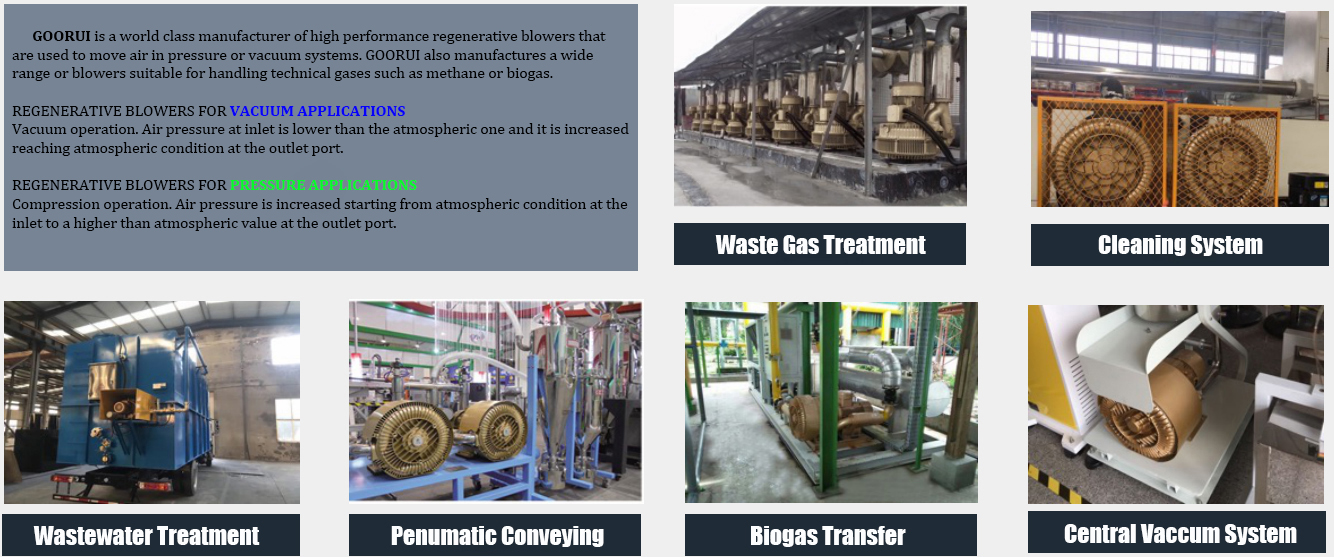

Vortex blowers find applications in a variety of industries and processes, including:

·Wastewater Treatment: Aeration of wastewater to support biological processes.

·Pneumatic Conveying: Moving materials like powders, granules, and other lightweight items through pipes.

·Dust Collection: Removing dust and particulate matter from industrial environments.

·Aquaculture: Aeration of fish ponds and other aquatic environments.

·Combustion Air: Providing air for combustion processes in various equipment.

·Scrap Collection: Removing debris and waste materials.

·Air Knives: Generating high-velocity air streams for drying, cleaning, or separating materials.

·Other Applications: Test air, soil remediation, tank agitation, air sampling, de-icing, food packaging, and more.

To learn more, or if you have a specific application, send us an email with your requirements. Please be sure to include required Flow Rate and Pressure/Vacuum Requirements.

You can email us at: service@goorui.com