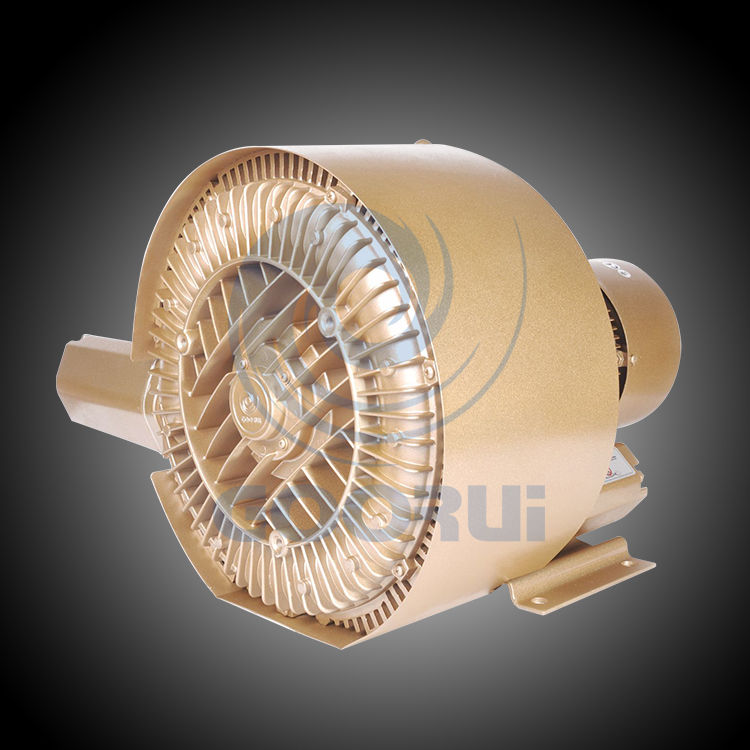

A regenerative blower, also known as a side channel blower or ring compressor, is a type of blower that uses a rotating impeller to move air or gas. It’s known for generating both pressure and vacuum and is commonly used in a variety of industrial and commercial applications.

Key Features & Working Principle:

Impeller:

A rotating impeller with blades accelerates the air or gas, creating pressure and vacuum.

Side Channels:

Separate ring-shaped channels on either side of the impeller guide the air flow, allowing for recirculation and increased pressure.

Regeneration:

The air is repeatedly accelerated and recirculated within the side channels, resulting in a “regenerative” effect that enhances pressure development.

Contactless Operation:

The impeller spins without direct contact with the housing, minimizing wear and maintenance needs.

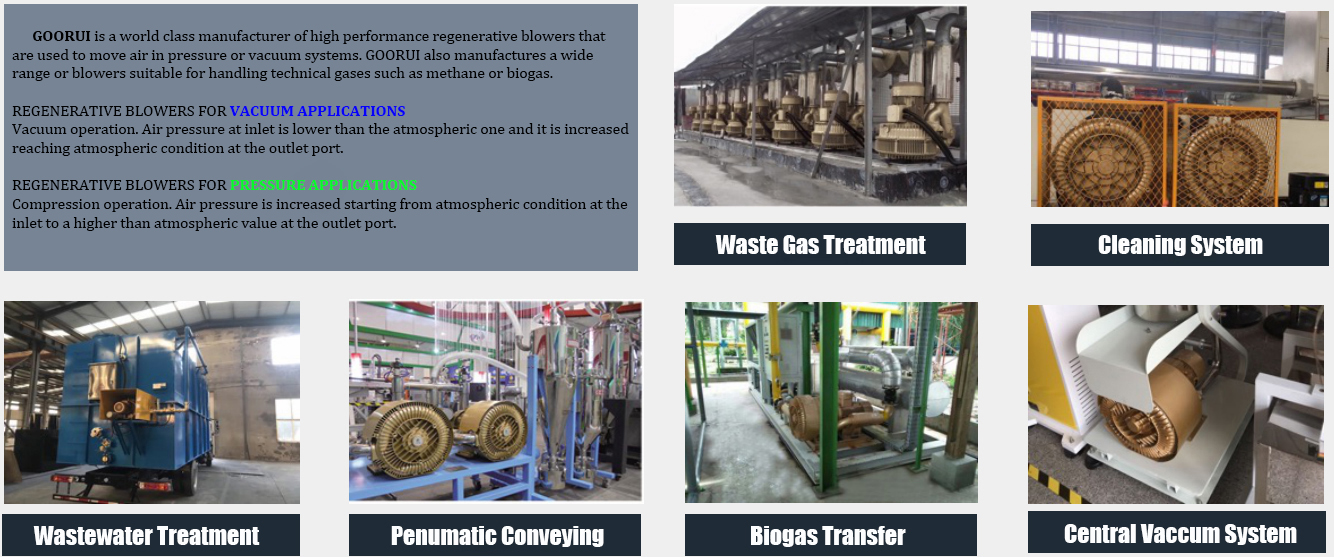

Applications:

·Pneumatic Conveying: Moving materials through pipes or hoses.

·Wastewater Treatment: Aeration and oxygenation in wastewater applications.

·Industrial Drying: Removing moisture from various materials.

·CNC Machining: Suction mounting for chip and dust removal.

·Vacuum Packaging: Creating a vacuum for sealing and preservation.

·Medical Devices: Used in some medical and surgical equipment.

Advantages:

High Pressure and Vacuum:

Regenerative blowers can achieve higher pressure or vacuum levels compared to some other blower types.

Oil-Free Air:

They typically deliver oil-free air, which is important in sensitive applications.

Compact and Lightweight:

Compared to some alternative blowers, regenerative blowers can be more compact and lightweight.

Energy Efficient:

They are often more efficient than equivalent air compressors in terms of energy consumption.

Quiet Operation:

Regenerative blowers can be designed to operate relatively quietly.

Low Maintenance:

Due to their contactless design and durable components, they generally require minimal maintenance.

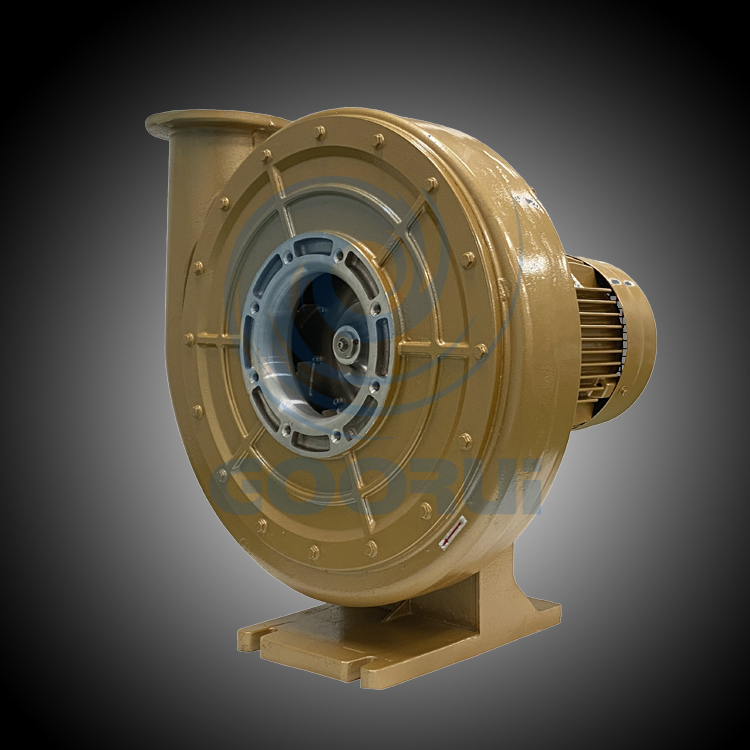

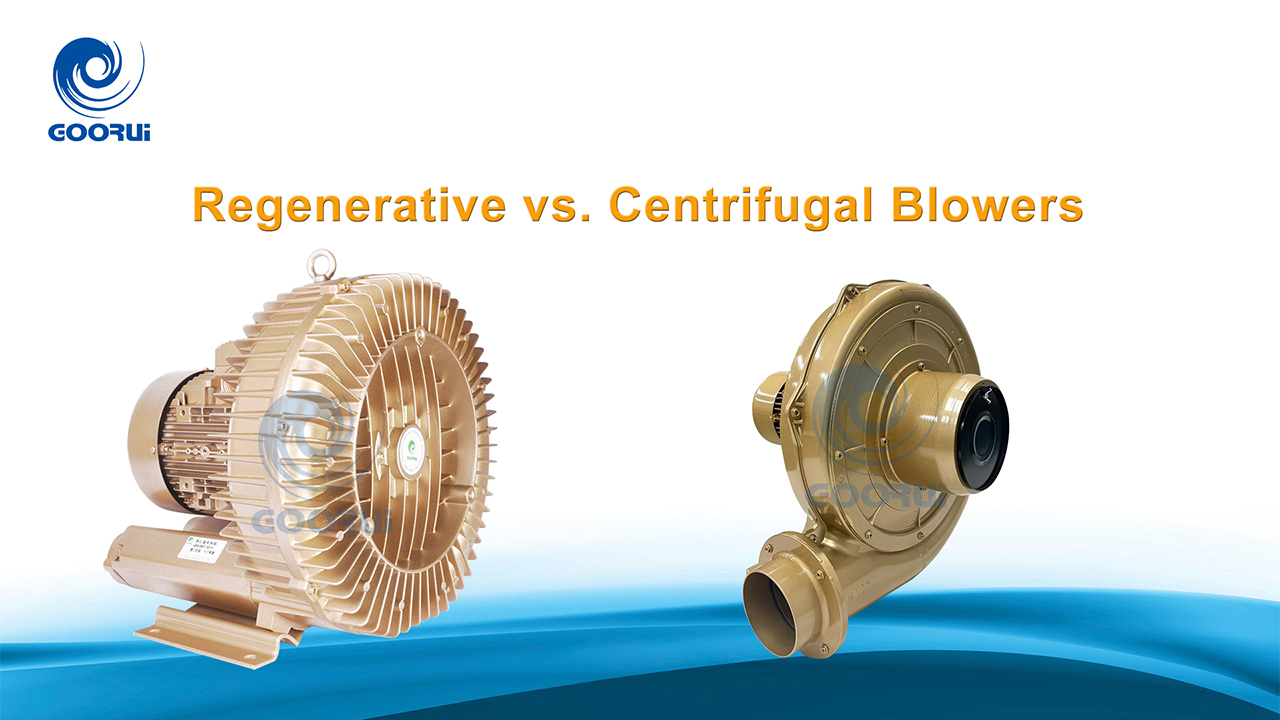

Distinction from Centrifugal Blowers:

Pressure vs. Flow:

Regenerative blowers are generally considered high-pressure, low-flow blowers, while centrifugal blowers are typically low-pressure, high-flow devices.

Air Path:

Centrifugal blowers move air through a single path, while regenerative blowers recirculate the air for increased pressure.

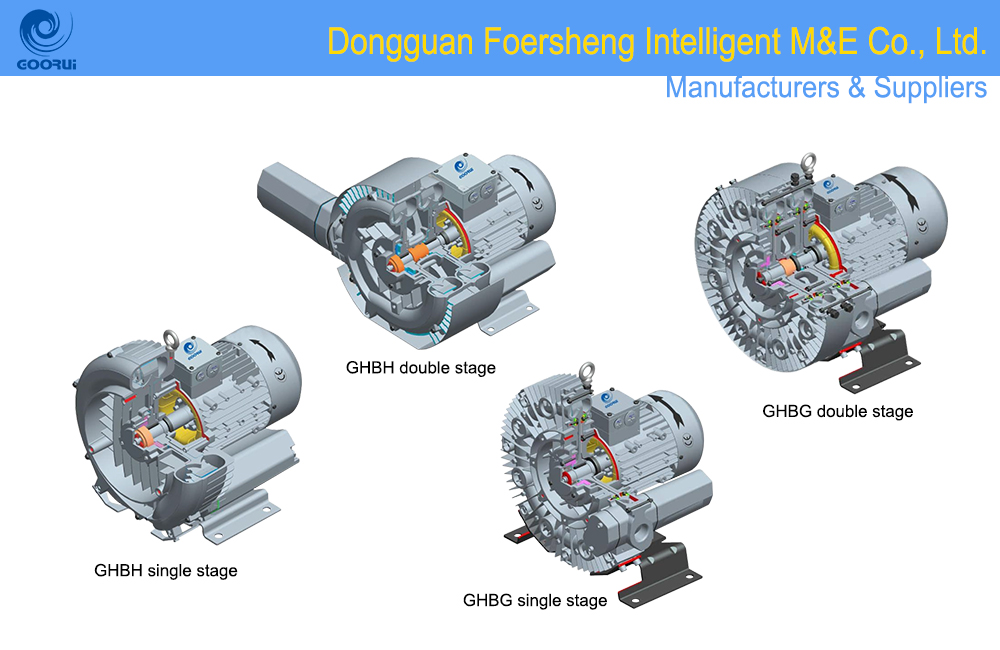

Types:

·Single-stage: Air travels around the impeller once before being discharged.

·Dual-stage: Air is channeled around the impeller twice for increased pressure.

If your business depends on quality performance from air technology equipment, then come and talk to GOORUI to find out more about our air technology services and solutions.

To learn more, or if you have a specific application, send us an email with your requirements. Please be sure to include required Flow Rate and Pressure/Vacuum Requirements.

You can email us at: service@goorui.com