The core role of high-pressure ring blowers in the production and post-processing of finished plastic products is to achieve material conveying, shaping, drying, and cleaning through high-pressure, high-velocity airflow. Specific applications are concentrated in the following four scenarios:

Plastic Finished Product Conveying (Core of Automated Production)

Utilizing the thrust or suction of high-pressure airflow, this technology enables automated transport of finished plastic products (such as plastic granules, pipes, sheets, and injection-molded parts), eliminating manual handling losses and improving efficiency.

Typical scenarios: Plastic parts produced by injection molding machines (such as appliance housings and toy parts) are transported directly from the mold outlet to subsequent sorting/packaging stations via negative pressure suction pipes generated by high-pressure fans. In plastic pipe production lines, positive pressure airflow propels pipes from the shaping machine to the cutting stage.

Shaping and Cooling Finished Plastic Products (Ensuring Dimensional Accuracy)

After forming, finished plastic products (especially extruded products) are rapidly cooled by strong airflow from high-pressure ring blowers, fixing their shape and dimensions and preventing deformation.

Typical Scenarios:

Plastic Film/Sheet Production: After the film exits the extruder die, a high-pressure ring blower blows air between the cooling roller and the film, accelerating cooling and shaping to ensure smoothness.

Plastic Profiles (such as door and window frames, decorative strips): Before extruded profiles enter the cooling water tank, they are pre-cooled by high-pressure ring blowers to prevent cracking or dimensional deviation caused by large temperature differences upon entry into the water.

Drying Finished Plastic Products (Removing Surface Moisture/Oil)

After production, finished plastic products (such as cleaned recycled plastic parts and freshly cooled extruded parts) are prone to residual moisture or release agent oil on their surfaces. High-pressure ring blowers can quickly dry them with powerful airflow, preparing them for subsequent processing (such as printing and painting).

Typical scenarios: In plastic bottle/can production lines, after washing and disinfecting bottles, the high-pressure blower’s circular airflow provides a 360° sweep to dry out moisture from the inside and outside of the bottles, preventing contamination of the liquid during subsequent filling. Before painting the surface of plastic toys, high-pressure airflow is used to remove surface dust and residual release agent, improving coating adhesion.

Cleaning and Sorting of Finished Plastic Products (Improving Product Cleanliness)

High-pressure airflow removes dust, debris, and other impurities from the surface of finished plastic products, or assists in sorting out defective products.

Typical scenarios: After screening finished plastic pellets, high-pressure ring blowers are used to remove dust from the pellets’ surfaces. In the plastic parts sorting process, the airflow impacts the displacement differences between finished products of varying weights to separate defective parts (such as plastic caps with missing corners).

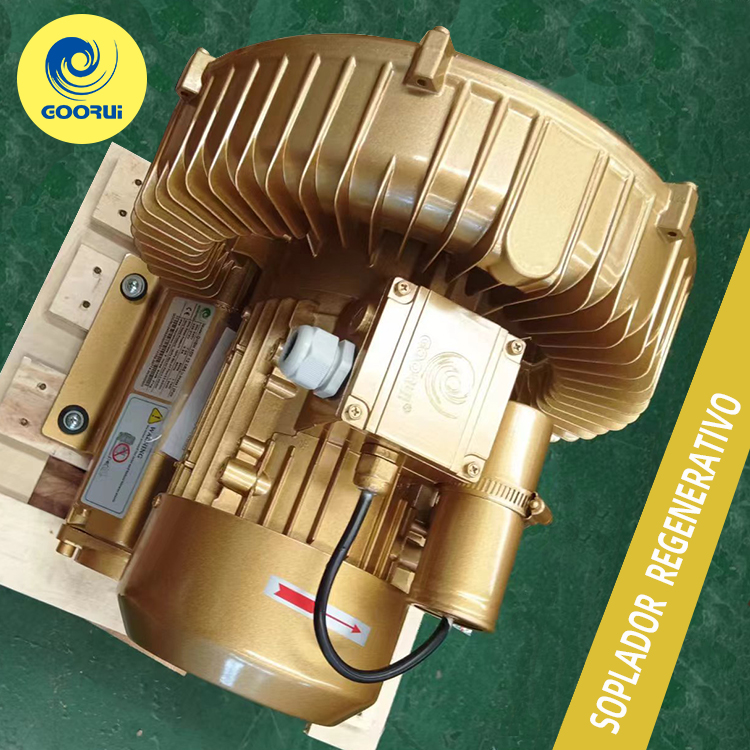

With flexibility and diversity, GOORUI team is always committed to providing quality side channel blower (ring blower, regenerative blower, vortex blower, vacuum pump, high pressure blowers) to customers in different industries for multi-applications of aerobic aeration, wastewater treatment, sewage treatment, pneumatic conveying, pharmaceutical machinery, garment machinery, wood working, plastic machinery, printing machinery, textile machinery, packaging machinery, garment machinery, paper processing, industrial cleaning machinery, air knives, dental suction equipment etc. Please contact with GOORUI blower sales representative for model selection and getting our best quotation.