The reason why regenerative blowers have become the “standard equipment” in sewage treatment plants lies in their ability to efficiently and stably address the key demands in the sewage treatment process – aeration and oxygen supply as well as material transportation.

Core application: Providing “oxygen” for biological treatment

The core link of a sewage treatment plant is biological treatment, which requires a large number of aerobic microorganisms to decompose the organic matter in the sewage. The regenerative blower serves as the “oxygen supply pump” in this process, and its role is irreplaceable.

· High-efficiency aeration: The regenerative blower can compress air and inject it into the aeration tank in the form of tiny bubbles through the aeration disc/pipe. This method features small bubbles and a large contact area with sewage, with an oxygen utilization rate of up to 20% to 30%, which is much higher than that of ordinary fans.

· Maintain microbial activity: Stable air pressure and large air volume can ensure that the dissolved oxygen concentration in the tank remains within the optimal range of 1.5-2.5mg/L, preventing microbial death due to oxygen deficiency and guaranteeing the treatment effect.

· Mixing and stirring: While aerating, the airflow can also drive the sewage to circulate and stir, preventing sludge sedimentation, allowing microorganisms to fully contact pollutants, and enhancing the degradation efficiency.

Auxiliary function: Address the transportation demands of multiple links

In addition to the core aeration, the regenerative blower can also cover other key scenarios in sewage treatment, achieving “multiple uses with one machine”.

· Sludge treatment: In the sludge dewatering process (such as belt filter press), regenerative blowers can generate high-pressure air flow to blow away the residual sludge on the filter cloth, clean the filter cloth and restore its air permeability, ensuring the dewatering efficiency.

· Water level control: Used in air-lift pumps, it conveys sewage or sludge from low water level areas to high water level areas through compressed air without direct contact with sewage, reducing equipment corrosion and clogging.

· Filter backwashing: In the filtration process, regenerative blowers can provide strong air flow to backwash the filter material (such as quartz sand), blowing off the impurities trapped by the filter material and restoring the filtration capacity of the filter.

Adaptability advantage: It meets the operational requirements of sewage treatment plants

The inherent characteristics of regenerative blowers make them more suitable for the harsh environment of sewage treatment plants than other types of blowers.

· Corrosion resistance: Some models can be made of stainless steel or coated with anti-corrosion materials, which can withstand the erosion of acidic, alkaline substances and moisture in sewage, reducing equipment failures.

· Stable operation: Compared with Roots blowers, regenerative blowers have lower noise and less vibration, and can stably output within a wide pressure range, adapting to fluctuations in sewage volume and quality.

· Energy consumption and cost balance: Under medium and small-scale oxygen supply demands, the energy consumption of regenerative blowers is lower than that of centrifugal fans, and the initial procurement cost and later maintenance cost are also more advantageous.

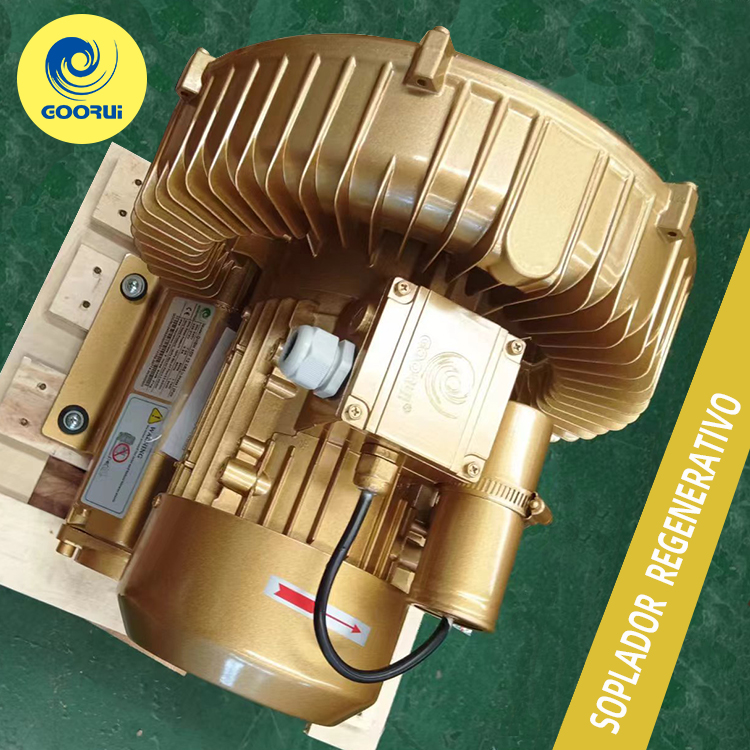

GOORUI in Sewage Treatment: Efficient, Reliable, Proven.

In the demanding world of water and sewage/wastewater treatment, precision and durability are everything. GOORUI high-performance regenerative blowers are engineered to meet the toughest environmental challenges – from aeration and ozone generation to vacuum filtration and sludge drying.

Why GOORUI?

✔ Energy-efficient & maintenance-friendly.

✔ Durable under continuous operation.

✔ Widely adopted in municipal and industrial water projects.

Trusted by global partners, GOORUI supports clean water initiatives with proven air movement solutions.

Interested in how GOORUI can power your next project? Let’s connect!