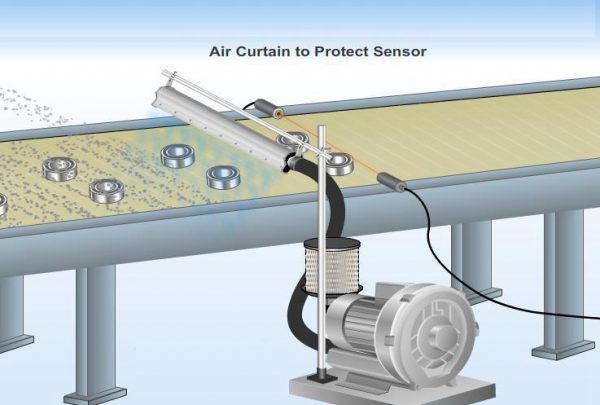

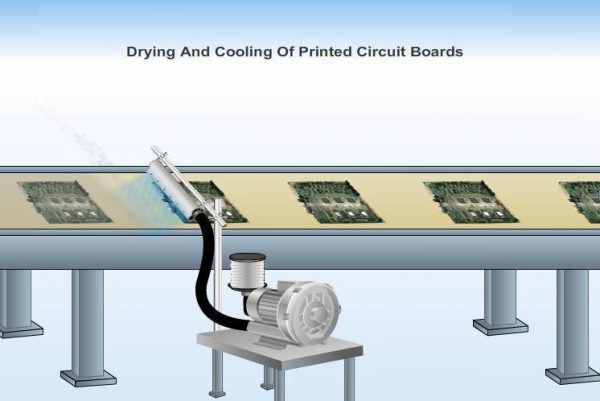

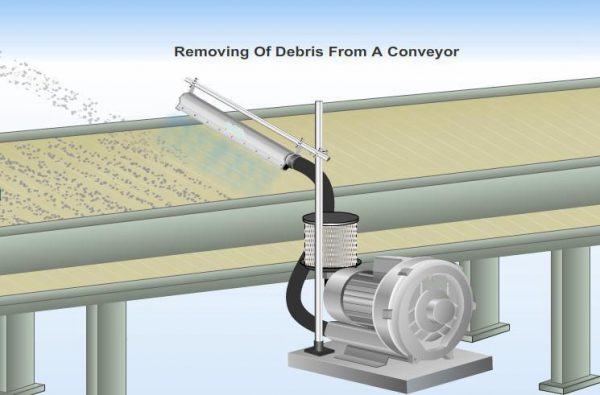

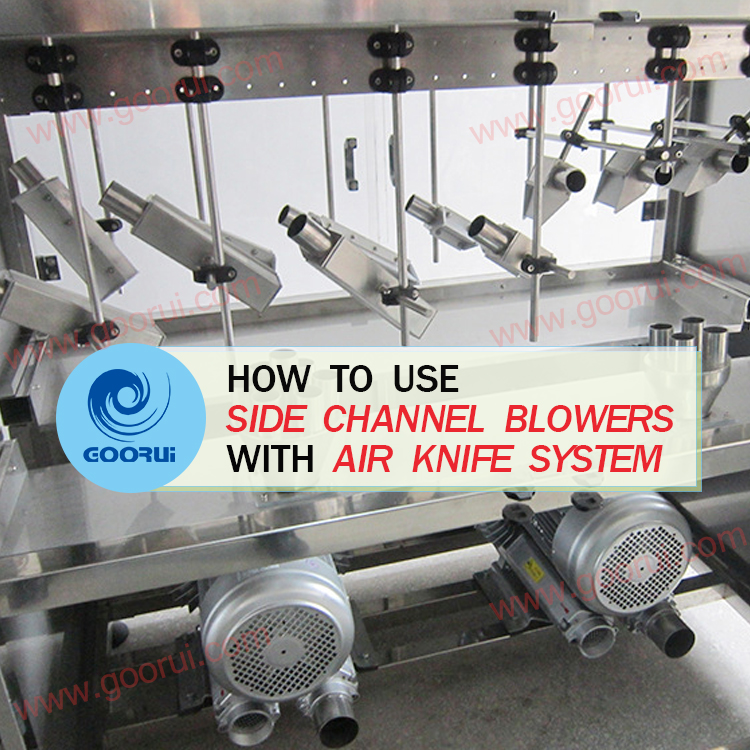

An air knife system is meant to use Side Channel Blower /Regeneratibe blower blow off any remaining substance (such as dust, water or any other liquid or debris) from products on a conveyor. These products have typically been washed or have been dipped in a liquid that needs to be dried for packaging. This is where an air agitation blower comes into play. As the product moves down the conveyor it passes through the airstream to be dried.

Air Knives for applications such as;

Drying vacuum-packed food products discharged from hot water shrink tunnels.

Drying conveyor belts after washing.

Removing “sticky” meat cuts from conveyor belts.

Removing machining swarf from alloy wheels prior to X-ray.

Removing excess lubricating oil from pressed metal plates.

Removing water from food cans after pressure cooking.

Bottle drying, plastic and glass fizzy drink bottles.

Bottle drying, wine bottles.

Blowing excess flour from meat pies.

Blowing excess paint from pre-painted building panels.

Drying plastic produce crates.

Density separation of bark and stone.

Removing water from washed fruit and vegetable products.

Dust/debris removal from bulk milk powder bags.