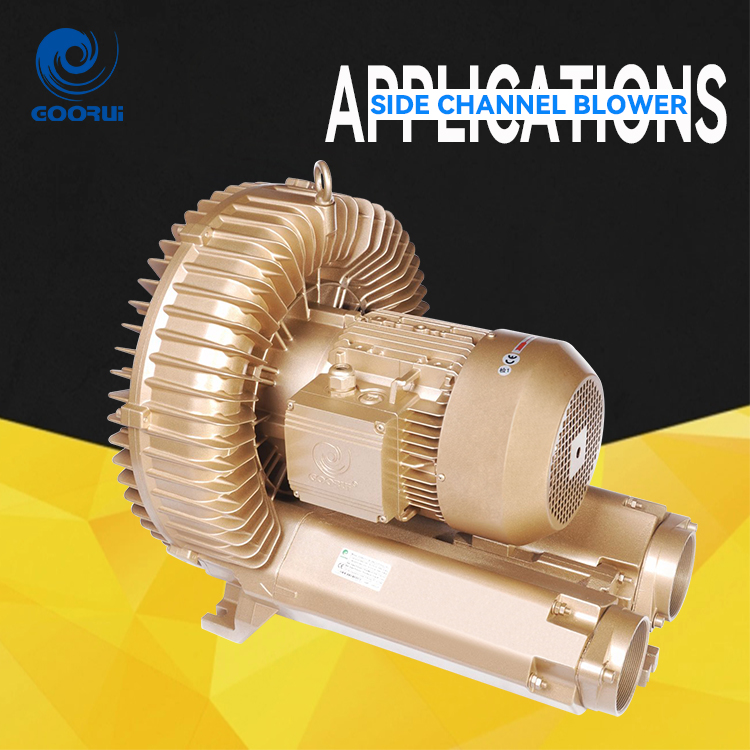

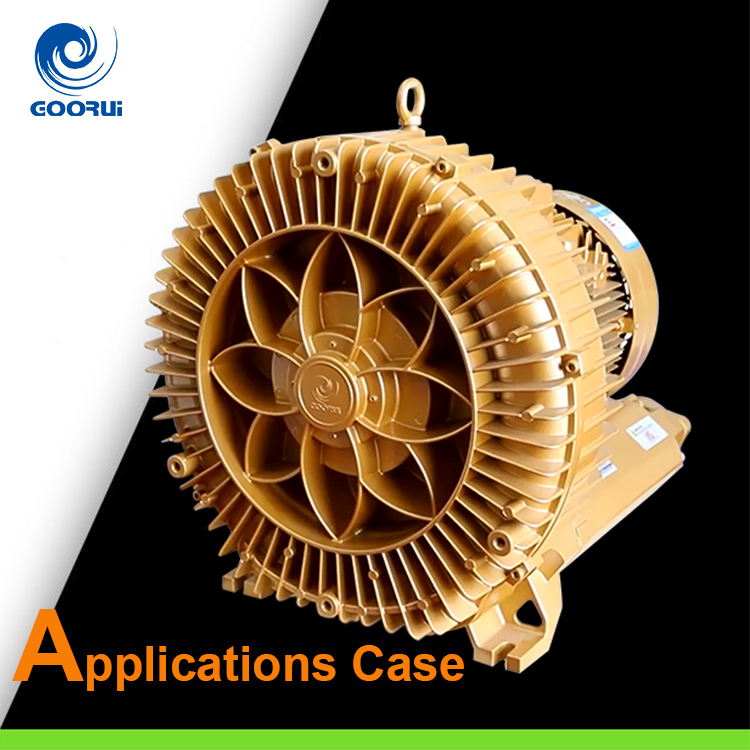

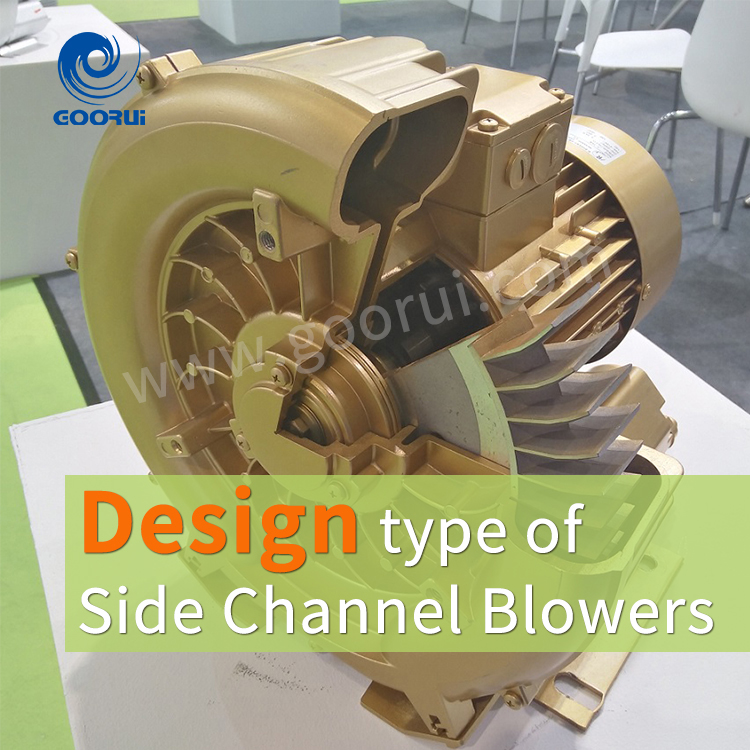

GOORUI side channel blowers are used for air, gases and for pneumatic transport, with no material passing through the pump housing. In vacuum applications, GOORUI products have proven their reliability for central dust extraction systems, point extraction, cooling and vacuum lifts. In pressure settings, clean and dry blowing with air are common applications as well as aerating pools, blowing-off tanks, packaging machines and various applications in the biology and chemical industry. Standard versions are suitable for all non-corrosive and non-flammable gases between -20° and +40°C. All versions of GOORUI side channel blowers are extremely suitable for continuous operation.

Applications

Side channel blowers provide reliable solutions for many different industries. View the many blower applications below.

Air Knife Drying / Air Knife Blow-off

An air knife system is meant to blow off any remaining substance (such as dust, water or any other liquid or debris) from products on a conveyor. These products have typically been washed or have been dipped in a liquid that needs to be dried for packaging. This is where an air agitation blower comes into play. As the product moves down the conveyor it passes through the airstream to be dried.

CNC Router Vacuum Hold-Down and Collection

Using the vacuum side of a regenerative blower, a CNC router table holds down the product to assist in the process of cutting and/or ornamentation. A centrifugal blower is used for waste collection.

Dental Fluid Collection

A regenerative blower can be used to collect waste fluid from a dental chair to a collection tank.

Food Processing

Regenerative blowers can be used in the handling of delicate items, such as eggs in the food processing industry.

Hopper Agitation

Hoppers can sometimes become clogged by bringing material from a larger area down to a smaller area. A regenerative blower or centrifugal blower can be used to agitate the material inside to encourage movement to the smaller area of the hopper.

Material Conveying

Material is fed into the ducting from a hopper, and then conveyed down the pipe with the use of a regenerative blower.

Ozone/Vapor Extraction

The blower is being used to collect ozone and/or other vapors from a tank that can be used elsewhere.

SPA

A regenerative blower is being used to push air into a spa to create bubbles. Many of our smaller regenerative blowers can replace your current residential system with twice the efficiency.

Venturi-Waste Collection

Using the pressure side of the blower, vacuum is created through a venturi to collect waste or useful particles.

Waste Water Treatment / Tank Aeration

Microorganisms in an aquatic system require oxygen to breakdown waste material. This process is just one step in waste water treatment that ultimately results in a clean water source. When using our regenerative blowers and diffusers for aeration, we can assure maximum oxygen transfer efficiency in any waste water system.

Air Handling

Industrial blowers provide high and even airflow through the ductwork of a building. Air movement is achieved by large angle blades connected to the hub of the blower.

Dust Loading

Dust loading industrial blowers collect dust to improve air quality. For some industries, dust collection is an essential part of their operations as well as being a legal requirement under Environmental Protection Agency (EPA) regulations. Air quality regulations are for the protection of workers since air particulates can lead to a variety of health conditions.

Industrial dust loading units move air and contaminants through a system that captures, collects, and removes dangerous particles. Included in the system are hoods, air filtration systems, and collectors such as baghouses, traps, and ductwork.

Fume Extraction

A wide variety of industrial processes produce fumes, smoke, and chemicals that have to be removed from the air. The fumes and other contaminants are removed by scrubbers or points of emission. This is normally achieved through the use of a system of blowers and fans.

Fume remover industrial blowers are a part of a whole system that is designed with a large capacity filtration system. The 99% efficiency of the system guarantees that all harmful odors, contaminants, and gas fumes have been removed.

Material Handling

The material handling industry uses pneumatic pressure systems to move granular and powder materials to production. Industries such as the pharmaceuticals, food processing, agriculture, chemical, and cement producers require industrial blowers to remove fine particulates from the air.

Though normal fans can remove average particles, heavier materials have to be handled by abrasion resistant, heavy duty industrial blowers that are specifically designed to withstand the wear of such materials. Blowers for these types of operations are made of exceptionally sturdy materials and are capable of enduring the severe abuse from removing the chips, particles, and granular residue.

Saturated Air

Saturated air contains moisture or gases. The term saturated air refers to when the humidity in the air is at its highest possible point in regard to the pressure and temperature. Above the established point, condensation occurs. The danger of such concentration is damage to equipment from corrosion and rust, which requires the air to be removed and cleaned.

To produce the needed results of removing saturated air, customized industrial blowers are made that are corrosion and rust resistant, which means the use of stainless steel or metals coated in a moisture resistant epoxy. The manufacture of saturated air industrial blowers requires custom designed blower blades that can perform in wet environments.

Exhausting

In small and enclosed workspaces where paint and vapors accumulate, industrial blowers serve the purpose of removing and filtering the fumes and vapors to keep the air clean. Since some of the chemicals in these applications can be combustible, exhaust industrial blowers have to be spark resistant.

A buildup of paint, lacquer, and varnish has the potential of being volatile and explosive. The spark resistant blowers for these conditions are normally made with specially fabricated aluminum impellers.

Cooling

Cooling industrial fans are referred to as fluid displacers due to the fact that they displace air in one location to move it to another location through the use of rotating blades. The purpose of cooling fans is to blow in cold air and drive out hot air, which gives them the name of industrial cooling blowers.

To accomplish the multiple operations of pulling in cool air and driving out hot air, requires a specially designed blower. Cooling fans have a larger diameter, which allows them to move large volumes of air at low pressure. Though this single feature distinguishes cooling industrial blowers, their other components, such as the motor, rotor shaft, impellers, casing, and mountings, are the same as other units.

Blow-Off

In the manufacturing process, parts that need to be painted normally go through some form of cooling and cleaning process that can involve water, specs of dust, granules, or other forms of abrasive materials. Before the parts can be painted, the particulate matter has to be removed by the forceful application of streams of air, which is provided by an industrial blower.

Industrial blowers provide a sufficient amount of force and power to remove water vapor from cooling operations or matter that accumulates on parts prior to their being painted. Pressure blowers for this purpose are made of materials to create the necessary pressure and drive to eliminate and clean parts.

Material Conveying

Material conveying industrial blowers move air in a confined space to transfer and move various forms of granular and powder materials. Their main function is to generate air flow in a tube by creating a vacuum to pull granular, paper, powder, and pellet materials. The special nature of this type of blower requires that they be enclosed in a confined system to be able to perform pneumatic conveying. The type of material transport is considered to be the most efficient method for moving raw materials.

Wastewater Treatment

The purpose of industrial blowers for wastewater treatment is for tank aeration, which has to be maintained round the clock. The types of industrial blowers have to be highly reliable and be low maintenance. Another aspect of wastewater treatment is the potential for methane gas and other types of gases, which can be dissipated with industrial blowers.

Food Industry

The food industry makes special use of industrial blowers above and beyond the need for clean air. Any equipment for the food industry has to meet the demanding requirements of the Federal Food and Drug Administration (FDA) and must be completely sanitary to comply with industry regulations. Though clean airflow is a necessity for food production, there are several other functions that industrial blowers perform.

Prior to production, fruits and vegetables have to be cleaned of contaminants by being scrubbed. Before being placed into production, any residual water or possible contaminants have to be removed, which is done by an industrial blower. This is also true for bottles and cans used for packaging food products.

Soil Vapor Extraction

As industrial operations progress and businesses fail, there is a constant need for a means to ensure that soil is free of any lingering gases or toxins. Industrial blower exhausters are used to remove any possible toxins from soil to provide for safe environmental conditions.

Soil vapor extraction blowers are connected to wells and apply negative pressure to the subsurface to remove contaminants. The removed vapors are treated at the surface to guarantee total removal. The main parts of the system are the blower, its motor, and a moisture separator.

Mining

Of all of the different industries that rely on industrial blowers, the mining industry has the most obvious use as a ventilation system for underground mining. The harsh and demanding conditions of the mining industry requires that industrial blowers be robust and resilient. It is essential that they provide longevity, durability, and be maintenance free.

A concern for industrial blowers for mining operations is the dust, dirt, and particulates that can be damaging to blowers at mining operations. These hazards require that the blowers be specially designed with collection units or filtration systems.

Aquaculture

In the production of seafood, hatcheries play a vital part in the growing and cultivating of fresh and saltwater animals. Blowers are used to generate oxygen to help guarantee water quality and the freshness of food products. They are also used for feeding systems and the creation of bubble curtains. The main importance of air blowers for the aquaculture industry is the constant supply of fresh clean oxygen to ensure the life of the densely populated tanks.

Oxygen is a vital part of the survival of water animals, which makes aeration an important part of the production process. The aeration process maintains oxygen levels, provides constant oxygen levels, keeps water circulating, and offers protection against extreme temperature variations.

Pneumatic conveying systems offer a means of safely feeding the water organisms with pellets and powders. Industrial blowers ensure the smooth operation of pneumatic feeding systems. The versatility of industrial blowers makes them adaptable to any form of installation regardless of its location.

Oil Refining

Low pressure industrial blowers are a central part of conveying petroleum materials for product production. Part of the refining process is the production of toxic hydrogen sulfide. Thermal incinerators are used to oxidize the sulfur by cleaning it. Blowers enhance the combustion process to assist in further cleaning of the gases.

In the production of carbon, that is used to produce plastics, paints, and ink, combustion is used to produce the material. Blowers supply high volumes of air to the furnaces and assists in injecting natural gas, which allows thermal decomposition to occur.

Dust Collection

The size and volume of air that an industrial blower moves requires some form of collection system. Depending on the operation, that system can involve a receptacle, bag, filter, or some other type of collection device. The simple fact that industrial blowers stir up the air makes it a necessity to have some form of collection method to protect workers. The type and size of the collection is dependent on the size of the industrial blower and the space to which it is directed.

Soil Remediation

Remediation of soil is done when cleaning up accidental spills from vehicles transporting petroleum products and industrial solvents, or leaks from fuel storage tanks. It involves the extraction of volatile organic compounds such as hydrocarbons and solvents. A combination of pressure and vacuum systems is used to evaporate these volatile organic compounds by moving large quantities of air through the contaminated soil. The contaminated air is then processed to remove the hydrocarbons and solvents and allow safe and immediate exhausting into the atmosphere.