Many existing facilities in the packaging industry are upgrading their equipment to keep up with modern times requirements. Factory owners are searching for new reliable tools to deploy. Newly developed blower technology sees its employment for drying treatment. Protecting packaged materials from moisture can effectively assure higher quality for the end product.

Within the packaging process, regenerative blower applications are varied. These types of channel blowers are a valid and effective option for cutting factories’ operational costs. In this article, we will talk about regenerative blower machines and their utilization within the packaging industry.

About Regenerative Blowers

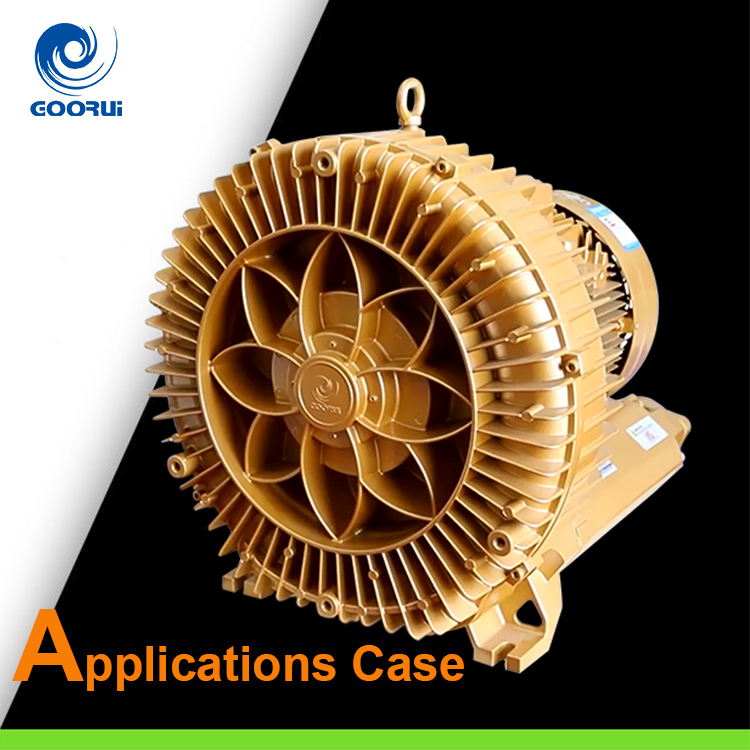

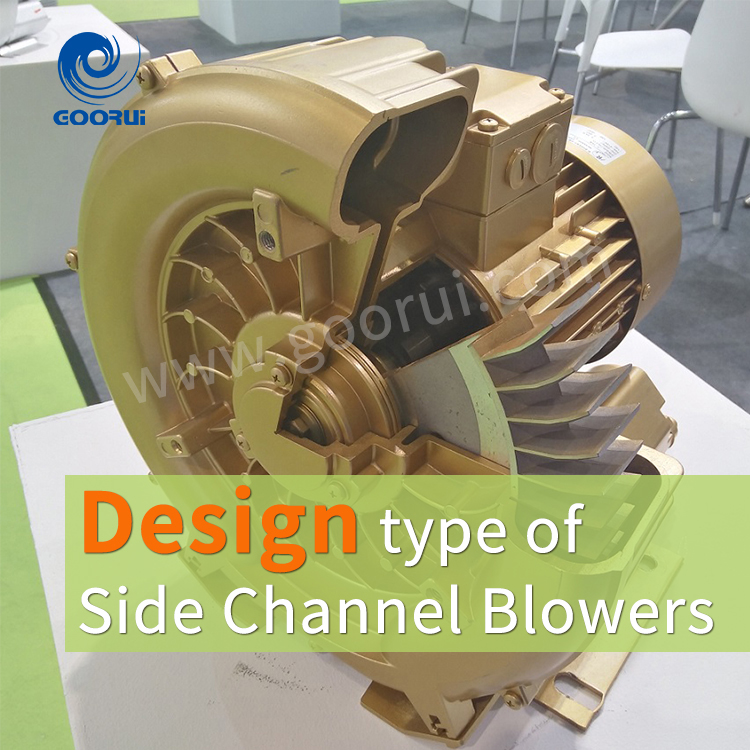

Regenerative blowers (also known as side channel blower and vortex blower) are one of the most versatile industrial blower types within the packaging industry. The equipment is powered by an electric motor shaft (usually of 2900 – 3500 rpm), which activates the impeller. The impeller consists of several radial blades spinning within a housing. The housing supports an inboard and outboard channel. Once the impeller rotates, the air is drawn in the inlet port and captured among the blades. At this point, the air is continuously being pushed outward and forward into the channels. This whole procedure is finalized to provide high pressure or vacuum through a non-positive displacement flow.

Among the many benefits, regenerative blowers are designed not to be requiring any maintenance and monitoring. The impeller is the only moving component, and it does not touch the housing channels resulting in the equipment to be virtually wear-free. A Regenerative blower operates without oiling, and do not have complicated suction and exhaust valving. On top of that, regenerative air blowers provide pulsation-free flow for a low vibration and noise level. Ultimately, the discharged air coming out of the machine is clean and safe.

Regenerative blower applications

Here we have reported some of the possible utilization of regenerative blowers within the packaging industry:

- Bottle Evacuation: Take out the oxygen and contaminants from bottles prior to filling to provide improved hygienic conditions. Some of the possible use can be adopted by beverages, cosmetics, and pharmaceuticals product package

- Drying Treatment: Often combined with air knife systems to remove moisture and debris before packaging. This employment is used above all with food cans.

- Dust Collection: Collect dust and debris from the area surrounding packaging machines. Here the primary purpose is keeping a clean working environment and ensuring other machinery optimal performance.

- Excess Product Removal: Remove and gather packaging scraps, eliminating the imperfections. Some of the examples could be trims from plastic-wrapped products, and cardboard boxes not suitable for wrapping.

- Gas Removal: Finally, blowers are used to evacuate the air and other gasses from plastic packs for more appropriate sterilization. Cereal and baked goods are just a few of the instances in which this process is applied.

Other than for packaging, regenerative air blowers are utilized in a wide range of fields: sewage aeration, vacuum lifting printing presses, aquaculture/pond aeration, spas, dryers, dust and smoke removal, industrial vacuum systems, pneumatic conveying and soil vapor extraction. For each of these applications, our company can offer customizable system solutions.